Thanks again dmorg1

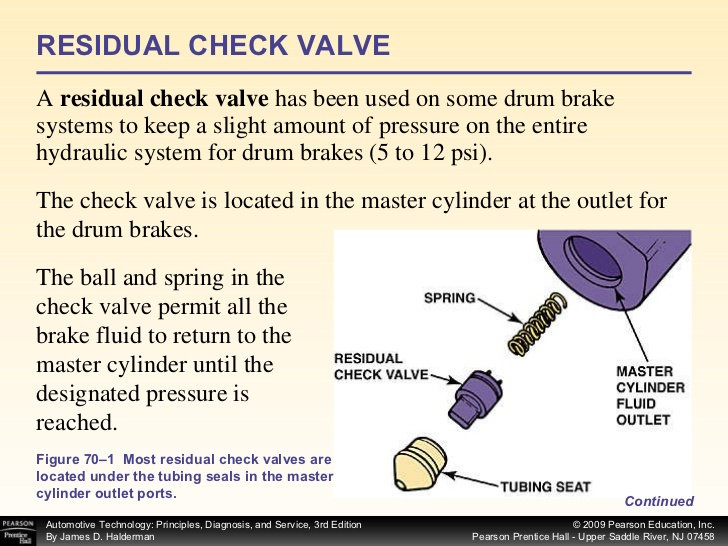

I wrongly assumed it was a simple spring-actuated check valve until I saw your diagram and others online. I couldn't figure out why the spring was on the "wrong" side of the "stopper". If it was a simple check valve, the seat would be on the reservoir side and the spring would be on the line side. Not so.....:

This drove me nuts and I clicked for an hour until I found an explanation for how the valve works. This is definitely NOT a simple check valve. Here is the best explanation of "how it works" that I found. This is very consistent with dmorg1's great explanation:

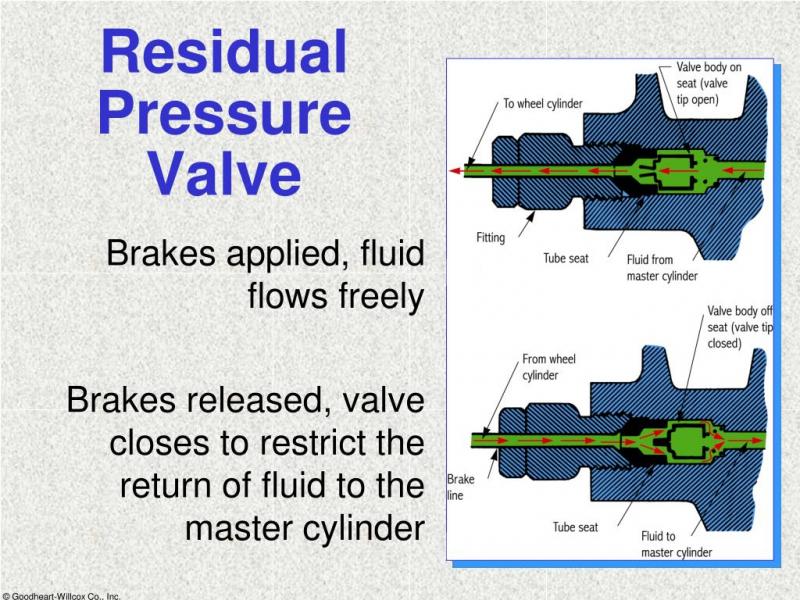

Unfortunately, the diagram is still missing the state when the valve is holding residual pressure. The bottom diagram shows line pressure exceeding the spring force and allowing fluid flow back into the master. Once the pressure reaches the "set point" or desired residual pressure, the spring will push the valve back into the tubing seat and the flaps in the rubber valve will close. So this diagram is missing an illustration like the upper diagram, only with the flapper CLOSED. This would be the state with residual pressure in the line.

The other question remains what happens when there is no residual pressure in the line. The valve will be seated against the tubing seat by the spring but not clear if the flapper valve will leak enough to allow gravity bleeding. I suspect it is possible and accept Sirrotica's experience that it does. As he said, cutting the line and looking for flow would be a compelling confirmation but I don't have a master with a check valve knocking around.