I'm back with another update on endurance testing painted welting. After I put the samples through the freezing tests I put the sample board up on a flat roof above my rear lanai. They got full sun and weather every day unless there was a hurricane possibility. It's been almost 3 years since I painted the samples and I'm really, really, impressed with the welting.

Results

No discernible fading, yellowing, or stiffening of unpainted samples.

No discernible fading, yellowing, or peeling of clear coated stock colored pieces whether adhesion promoter was used or not.

No discernible fading or peeling of BC/CC pieces whether adhesion promoter was used or not.

No discernible fading or peeling of single stage urethane whether adhesion promoter was used or not.

The single stage acrylic enamel with flex agent but without adhesion promoter has finally started peeling, it took much longer than I expected.

The single stage acrylic enamel with flax agent and adhesion promoter is still holding! Surprising!

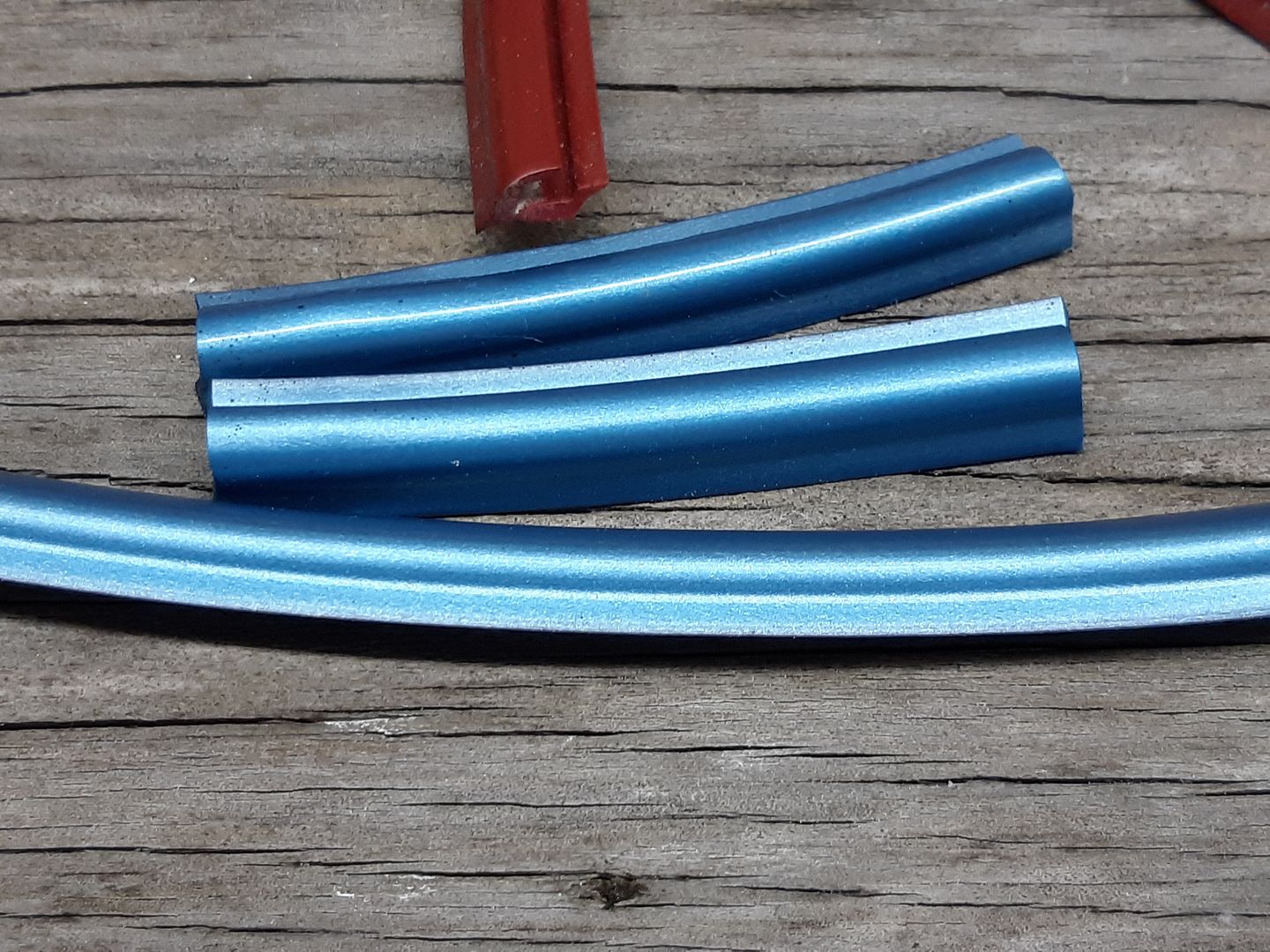

In the pics below the long piece of each color is the "control group" pieces that were stored in the house. The middle piece is stock color with no clear, and the top piece is stock color with clear coat. The bottom pic is the now failing single stage acrylic enamel with flex agent but without the use of adhesion promoter. I expect even the ones with the adhesion promoter will fail soon, but who knows? I didn't think any of the single stage acrylic enamel would survive the torture this long! I really bend and twist all the samples a lot, far more than anyone would installing the welting on flares.