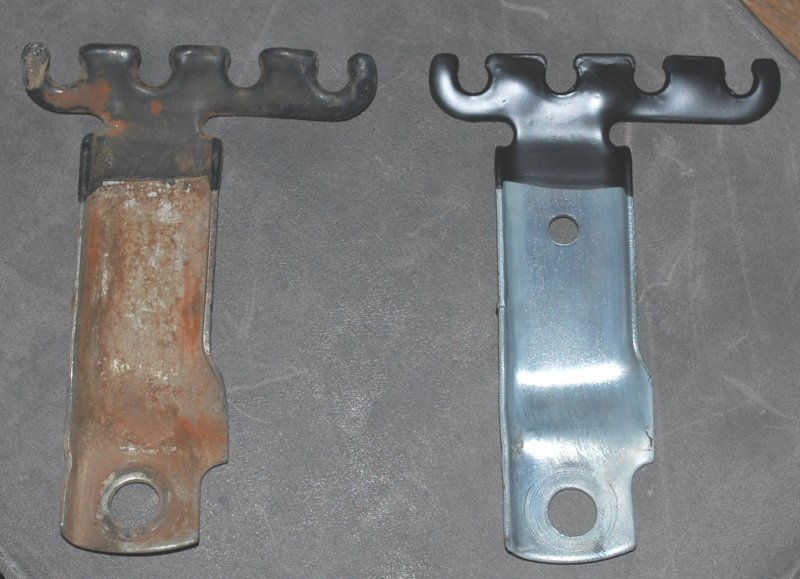

Latest Zinc plating work.

Some before after pics of the wire looms for my 68 GTO.

Tore, scape, burn off original plastic coating.

Power brushed the dirt/scale/rust off.

Bend, flatten back to original shape if needed.

Then dipped in pure muriatic acid (be careful) for five minutes or so to burn off the original zinc plating and rust.

Rinsed in clean water

Electro plated with Zinc (about 2.7 volts, holding by hand for five minutes or so)

Rinsed in clean water

Brushed with a fine brass wire brush.

Dipped in black "Plasti-Dip" (pretty much same process as originals)

Dip is still a bit thick in the photos because it's still drying.

Rather than buying new re-pops, restore the originals ... yes takes time, but stuff like this is how I can restore my car for a LOT less than the "gentleman" restores pay. And I end up with a more original vehicle.

As mentioned in prior pages of this thread, countless nuts, bolts, washers, brackets, straps, etc. than can be done this way. If it's got a zinc plated part (galvanized) and you can take it apart, you can plate it.

Everything doesn't always turn out this nice, but much of it does, and what doesn't has that genuine two year old original part look.

PS. Thanks to forum member Scott Thelander for selling me an original set to start with.