| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#261

|

||||

|

||||

|

photobucket fail :-)

Andrew |

|

#262

|

||||

|

||||

|

Pics will all return on the 28th when a new 'bandwidth month' starts.

This month has been pretty heavy out in the garage, and I like to take too many pics.

|

|

#263

|

||||

|

||||

|

Can never take too many photos to document this install. Keep up the good work.

__________________

Its ok to giggle and snicker, Dont laugh and point |

|

#264

|

||||

|

||||

|

.....arrived via truck freight last Tuesday, so today I took some time to get it ready to install.

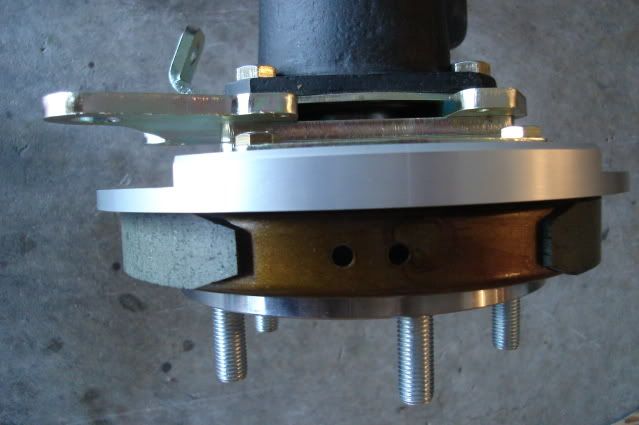

I did a little grinding on the driver's side upper control arm to provide clearance between the control arm pivot area and the top of the differential housing. A big thank you to member gearheads78 (Richard) on the Pro-Touring forums for the heads-up on this mod. Just goes to show that you need to pre-fit all of your new aftermarket components whenever possible.  Here you can see the tight clearance between the arm and the housing after grinding. It's a bummer when you have to grind on a freshly powder coated brand-new component, but a little black enamel takes care of the minor touchup needed.  I took the threaded ends of the arms apart and added a little more moly grease to the threads, I was glad to see they came with a decent amount of proper lube on them. These parts almost look too pretty to hide up underneath the car.  Here's the new 3.42-geared Eaton posi-equipped Buick A-body rear end with the Moser 30-spline axles and all of the KORE3 C6 Z06 rear brake adapter parts and internal parking brake components laid out.  The KORE3 kit comes with all of the proper spacers and brackets necessary to make the Corvette brakes a true bolt-on installation. The fully-machined billet aluminum parking brake backing plates are a true work of art, this high-quality kit was worth every penny.  A look at the parking brake assembly before the rotor is installed.  From the back side, the caliper and bearing retainer bracket is one piece.  From the top you can see the series of spacers as they stack up to make everything fit. First a .105" thick spacer between the bearing retainer/caliper bracket and the housing end, next two .250" thick spacers between the retainer/caliper bracket and backing plate. Last there is a steel plate about .100" thick between the aluminum backing plate and the four 3/8-16 flanged self-locking nuts that hold everything in place.  Both 13.4" rotors and 4-piston calipers are now installed to check for fit. These things are monsters!   These should help haul this soon to be very fast Tempest down quickly. Good brakes = a safer car.   That's all for today, tomorrow I'm hoping to be able to stuff this assembly under the car and check out how well my new 18X9" rear wheels & 275/40-18 tires will fit back there.  Hope you all had a great 4th of July, I sure did!

|

|

#265

|

||||

|

||||

|

Taper bearings on the rear axles for cornering?

Man looks like a cool deal, should send the pics into a magazine!

__________________

Skip Fix 1978 Trans Am original owner 10.99 @ 124 pump gas 455 E heads, NO Bird ever! 1981 Black SE Trans Am stockish 6X 400ci, turbo 301 on a stand 1965 GTO 4 barrel 3 speed project 2004 GTO Pulse Red stock motor computer tune 13.43@103.4 1964 Impala SS 409/470ci 600 HP stroker project 1979 Camaro IAII Edelbrock head 500" 695 HP 10.33@132 3595lbs |

|

#266

|

||||

|

||||

|

.....after work today, I stopped by the local Pep Boys and picked up a couple of 40" lengths of 3/16" brake line on the way home.

I ended up using 33.5" of line on the driver's side and 36" on the passenger side, owning a decent flaring tool is a must when shortening pre-made hard lines or making up new ones. The difference in line length was due to the offset location of the brake line tee on the top of the differential housing. The 8.5 rear has a cast-in bolt boss on top that's tapped for 5/16-18 thread to mount the tee, unlike the 8.2 rear these cars came with that use a bracket attached to the top cover bolt to mount the tee.  I bought some FlexKORE (TM) brake lines from KORE3 for the entire brake system to replace all of the flexible rubber lines, top-quality parts that will last forever and give better braking performance. I had to make sure that the FlexKORE lines were mounted in such a way that would allow the caliper to be pulled off the rotor for pad changes without disconnecting the lines.    I filled the rear end with 2.5 quarts of Castrol 80W-90 gear oil (no synthetic for limited-slip units) and a 4oz bottle of GM #1052358 Limited Slip Additive, after 1000 miles I'll dump the oil and refill with new. With the gear lube taken care of and the brake lines completed it's finally ready to install this weekend for sure.  Moving forward. |

|

#267

|

||||

|

||||

|

.....on the rear end install, I got up at 7AM because I knew it would be a long day out in the garage.

I pushed the Tempest out and laid out all of the rear suspension pieces: Currie Currectrac control arms, Global West S-60 springs, 1" rear sway bar, Bilstein shocks and some Hotckis mounting braces to reinforce the frame. I found that I was missing a couple of bolts that I needed for the Hotchkis mounting braces (used parts generously given to me by PY member Colin Frolick along with the 1" sway bar), so after spending a few hours removing the old rear end I headed to NAPA and picked up the Grade 8 bolts. I laid the new adjustable upper control arms next to the stock ones and slipped some bolts through them both. I adjusted the length on the new ones so they would match the stock ones to have a good baseline to start out with. I pumped all of the Johnny Joints and urethane bushings full of grease while I had easy access.  Out with the old.  I had read about the tight fit of the Currie arms to the frame mounting points, and sure enough there was about .010" of interference.   I used a slide hammer with a hook attachment and gave it about 3 hard knocks, this opened up the clearance that I needed. The mounting points are crushed inward a little by the previous tightening of the old suspension parts, it's not a big deal to open them back up again.  Control arms and mounting braces installed. On the lower arm on the pasenger side the very front end of the Currie arm interfered with the mounting bracket on the frame. I removed the arm and hammered the center of the mount in about 1/16" to get the clearance I needed. As you can see in the picture below, this was as low as the arm would pivot downward before doing the clearancing. You must remove the front grease zerk before installing these and put it back in when you're all finished, otherwise you'll break it off as the arm pivots down while putting the rear end in.  In with the new.   All buttoned-up. No sway bar installed yet nor any brake pads.  Suspension at full droop, shocks fully extended.  Rear end install complete, back down to earth.  I'm really liking the contrast of the black wheels and the red Corvette Z06 calipers.   I'm stoked. |

|

#268

|

||||

|

||||

|

.....from the weld shop today, it came out looking pretty good.

The welding on the crossmember was done by Jeff Moore at Chassis Fab in Acton CA. http://www.chassisfab.com/ Jeff does top-quality work and has a fully-equipped shop that can easily handle the small jobs like this one or bigger projects requiring extensive chassis fabrication. Now I'll be able to get the trans mounted in the car, this should add enough weight to make it easier to remove the front springs when I swap the old front end components for the new ones.

|

|

#269

|

|||

|

|||

|

While I'm thinking about this I should warn you to test fit your trans-dipstick with the engine and transmission out of the car. After I got the right bellhouse for my transmission the dipstick tube I had would not work. I used a 2000 Camaro tube, but I had to cut part of the mounting bracket off and bend the tube slightly to clear the back of the engine block. This would be next to impossible to do with the engine/transmission installed in the car. Maybe a tube from a truck might fit with no mods, but I already had the Camaro tube.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#270

|

||||

|

||||

|

Bart,

Have you checked into the new rack and pinion units for our A bodys, Flaming river sells them for a god awful 2500 Performance online has a similar setup for 1150.00 The nice thing about it is it eliminates the alternator to steering box clearance issue, However I don't know if the AutoKraft pan will interfere with the rack setup. I am collecting parts for my own 65 LS1 swap. Going to plan to use the same pan as you and the E headers. Like the looks of the Rack and pinion but.............

__________________

Eric CURRENT CARS 68 Firbird 400ci convertible |

|

#271

|

||||

|

||||

|

Eric,

Rack & pinion steering is definitely not going to be part of this build, I'm already tapped-out with all of the unplanned upgrades I've made to the brakes and suspension. I have a nice Lee 12.7:1 power steering box in the car that's 20 years old and still going strong. I was already having issues with the deep backspacing on the 18X9" front wheels, the rim was hitting the rearmost tube on the Hotchkis upper control arms near full steering lock. I bought the SPC adjustable uppers to gain some clearance there (straight adjuster vs outward curved tube) and it just sort of snowballed into a complete front end upgrade. The limited turning radius won't be any big deal. It was already reduced with the B-body spindles with their longer steering arms (I hardly noticed the reduced radius), the new ATS spindles will give me some turning radius back so it's probably a wash. Having the tierod end (grease zerk removed, a plug in there instead) touch the pan once in a while won't hurt it. If the new SPC upper arms don't have enough clearance to prevent the rim from rubbing, the limited travel of the centerlink will.  Bart |

|

#272

|

||||

|

||||

|

.....and took another step forward. The weather cooled down into the mid to low 90s today, last weekend it was close to 110 degrees

and just too hot to do anything. and just too hot to do anything. I put the Tempest up high on small wooden pallets once again and removed the passenger side header. The headers need to be out of the way so I can remove the lower control arm bolts, a complete front suspension upgrade is my next task. While doing some fitting and checking I found that with the transmission bellhousing just barely touched one of the passenger side header tubes right where the starter goes. I knocked off the corner of the bellhousing with a large flat file to give the header tube some clearance.  Next I bolted the trans up to the engine. I bolted the finished trans crossmember to the trans mount and jacked it up tight against the bottom of the frame.  After drilling three 5/16" holes in each side of the frame using the crossmember holes as a guide I bolted the trans crossmember in place using the upper and lower reinforcement plates I made previously.  The crossmember and lower reinforcement plate hang a little over 5/16" below the bottom of the frame rail.  Right above the exhaust clearance hump you can just get your finger between the top of the crossmember and the floorpan, about 1/2" to 5/8" of clearance.  Finally, I would like to thank my two daily drivers for their patience, putting up with numerous cold starts when they're getting moved around and for braving the hot sun all day whenever the Tempest is getting attention.  They're both very spoiled and really hate sitting outside. They're both very spoiled and really hate sitting outside. Now there is finally enough weight over the front end to start to compress the springs, the added weight of the 4L70E trans got the front suspension off of the upper bump stops. Next up is all of the front suspension and brake work, stay tuned. |

|

#273

|

||||

|

||||

|

.....by removing all of the old front end components.

I put the Tempest up on two large 6-ton jackstands and removed the wheels, then removed both front shocks and the sway bar end links. Next I loosened up the tie rod adjusters, but left the tie rods attached for now so they would help keep the spindles from moving while loosening up all 4 of the ball joint castle nuts. After removing the cotter pins and loosening the ball joint castle nuts by a few turns I used a 12" long by 1" diameter brass bar as a drift to knock them loose from the tapered holes in the spindle. After only a couple of hard raps on the ball joint studs with a 2-pound hammer they popped right out of the spindle, against the loosened castle nut. The brass bar is long enough to do all of your hammering clear of the suspension parts, plus you can get a good swing with the hammer.   Next I put my floor jack with a 2X6 wood block underneath the control arm spring pocket and jacked it up enough to remove the tension against the castle nuts. After removing the castle nuts I let the jack down just enough to get the spindle assembly out, I disconnected the brake hose at the frame bracket beforehand.  The H-O Racing front springs are fairly short and came out easily after letting the lower control arms all the way down with the jack, I didn't need to use a spring compressor. Having enough weight on the front end is the key to getting away without the need for a spring compressor, along with a short free-height spring.  To get the upper control arms off I had to remove the rubber spash shields from the inner fenders to get enough room to manuever them out. I also had to take the steering shaft loose from the rag joint coupler on the driver's side and push the steering shaft over as far as possible to get the control arm shaft off the 2 mounting bolts that are pressed into the frame. Tear down is now complete, all I need to do now is a little cleaning of the suspension attachment points on the frame and I'll be ready to start installing the new parts.  There's really nothing wrong with the old '78 B-body spindles with 12" rotors, reinforced stock lower A-arms and Hotchkis upper control arms with greasable poly bushings. They truly made a night and day difference in braking and handling over the original factory 9.5" drum brakes and rubber-bushed suspension pieces that had over 140K miles on them.  I'm replacing them all now with SPC adjustable upper control arms and tubular lowers, American Touring Specialties AFX forged aluminum spindles and C6 Z06 brakes with hopes that I'll see yet another night and day difference in braking and handling. This is really going to be a fun canyon carver.

|

|

#274

|

||||

|

||||

|

Awesome!

|

|

#275

|

||||

|

||||

|

Jeez !

That thing's gonna be a helluva ride, handle like a corvette and get you great MPG like a chevette Nice work as usual B-MAN

__________________

Knock Knock Knockin' on 11's Door '70 Judge, Palladium Silver w/Red Interior Powered by SD Performance, Ported 6X Heads 501 HP, 554 ft lbs TQ 12.14 ET @ 114 MPH , Supercase Muncie M22, 3:55 Suspension: HO Racing, BMR< Sykorat, and Bilsteins Narrowed 12 bolt , 16x8 VintageWheel Works, Comp T/As on street, MT Drag Radials @ Strip http://www.sdperformance.com/custome...1.php?carID=42 |

|

#276

|

||||

|

||||

|

I am so happy you took on this project so that I can watch all the great progress and see the amount of $$ and hard work, skill , product display. When you finish this badass, come up north and put a whoopin' on my ole chevelle and we will tear up some rubber, burn some fuel, then cool off at the beach drinkin a coupla road sodas and checking out the "poly Dollies" from SLO :>) lol bring that bad dog Poncho on!!!!

|

|

#277

|

||||

|

||||

|

Thank you.

Quote:

Quote:

Thanks for the kind words friend. It will be a while before the Tempest is ready, but I can oblige your ol' Chevelle with another partner to burn a little rubber with as a preview. My WS6 is always ready to go road trippin', hitting the beach and checking out wine country looks good to me. Bart

|

|

#278

|

||||

|

||||

|

Sure thing B-man, bring the vert ( chick magnet ) and I'll be invisable in the

Chevelle!!! How does that work? Like bringing a knife to a gun fight. NOT! LOL I'll take my chances with your ole A-body vrs my ole A-body when you get that Poncho on the road, but you are welcome anytime you need some fresh air and vino and a little SLO life!!

|

|

#279

|

||||

|

||||

|

.....the new front end today. The weather has cooled down during the last week to the mid to low 90s, so I'd better take advantage of that and get some work done on the Tempest.

New front suspension components laid out, I'll be reusing the H-O Racing front springs.  I laid the SPC upper control arms over the Hotchkis arms and adjusted the links to get them close to where they'll need to be. Before doing this I took the links apart and put a good coat of moly on the link threads. The curved rear tube on the Hotchkis arm interfered with my 18X9" wheel at near full steering lock, I'm hoping to gain some clearance at that point. The mounting holes in the new A-body Moog upper ball joints wouldn't line up with the two outward bolt holes in the SPC arms, those two holes are driled a little too far apart. A little work with a rat-tail file to slot the holes inward by .020" each took care of the slight mismatch. The mounting holes are already drilled to .300" in the arms which is plenty of clearance for a 1/4" bolt. I didn't like having to file on my new control arms, but after thinking about how much I had to hammer the crap out of my trans tunnel it didn't seem so bad.  I bought some new hardware to attach the upper control arms to the frame, the billet aluminum cross shafts are drilled for 1/2" mounting hardware so the original 7/16" bolts wouldn't work. This gave me the opportunity to gain some additional clearance between the headers and the bolts, the new hardware is 1/2" shorter.  Upper control arm bolted in place. You have to bend the rear corner of the opening in the inner fender inward to clear the rear control arm pivot on the cross shaft, this slight modification was already done to make the old Hotchkis arms fit.  The bare aluminum AFX spindles and cast aluminum lower spring seats were treated with an aluminum cleaner (Alumiprep #33) with an alodine solution (Alodine #1001) to protect them from corrosion. You can buy them from Aircraft Spruce: http://aircraftspruce.com  The SPC lower control arms went in easily using some new 1/2-13 Grade 8 hardware and nylock nuts, these arms already have a 1" drop built into them. After making sure the top of the spring was correctly clocked in the upper spring seat I dropped the aluminum lower seat into the control arm and made sure that it was clocked correctly as well. I was able to pull the lower arm up into postion with the spring in place by hand and slide the jack underneath it, no spring compressor needed.  AFX spindle is now in place, there's just enough weight in the chassis to compress the spring so the ball joints would mate up with the spindle. The castle nuts on the ball joints were snugged lightly at this point. If I don't like the ride height after the car is fully assembled it will come apart easily so I can either cut the springs or add spring spacers under the spring seats.  The billet aluminum ATS steering arms are now in place along with the Moog tie rod ends. Most of the major components are not tightened up yet, things will be coming apart a few times to make various adjustments.  The front suspension assembly is complete enough now that I can see how everything is fitting up, it's looking pretty good at this point.  Tomorrow I'll try to get the front hubs mounted to the spindles and see how the brakes, wheels and tires fit.

|

|

#280

|

|||

|

|||

|

Excellent work documenting this! I am hopefully a few months away from installing my own AFX spindles. And will look to your examples.

|

| Reply |

|

|