| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#61

|

|||

|

|||

|

For those not familiar with the '64 Fremont PHS Docs, they are very different in format from the other Plants.

They list the options by UPC. In this case, B10 does identify the "INSERT PANEL". However, this code is found on all GTOs built at the Fremont Plant. Undoubtedly, it does refer to the swirled insert panel included with the GTO option. You will also see that a few options on the Fremont form will show an asterisk. This was their way of noting options that were included as standard that were extra cost on other models. For example, the Lemans will show "*A50 BUC STS" because Bucket Seats were standard equipment while they were available as an extra cost option in certain Tempest Custom models. It isn't clear why the Insert Panel was not asterisked as it was a standard item included with the extra cost GTO option. Dual exhaust was a standard item included with the GTO option too and it was asterisked. But the Insert Panel listing never was. If there were any wood grain inserts installed on any Fremont builds, I would not know how they were coded. All I can say is that "B10 INSERT PANEL" will be listed on all of the GTO docs I have seen for GTOs built with the expected swirled dash insert. BTW, if the guy's copy is difficult to read, I could help translate some of the boxes. It helps to see a record with very clear print to understand one that is not so clear. War Beagle, the p/ns are found in the '66 Master Parts Catalog (MPC). The Packages are listed in Gr. 3.429. I have speculated on what specific parts would be in the kit PACKAGE based on the sequence of p/ns assigned to the various parts. The only other "documentation" has been the various mag articles of the period. Some of them did a pretty good job of detailing the various parts provided in the kits. Some of the articles pertained to big cars, '63s, etc. So you have to make some educated guesses too. But enough info is out there to make a pretty solid conclusion IMO. ALong with the physical evidence of course. I don't have the documents myself, but I'm told these p/ns exist in the later Parts Price Lists until they were discontinued around '73/'74. I have no other factory documentation however. |

|

#62

|

||||

|

||||

|

March 1961 Hot Rod had an article "What Makes Pontiacs Run?" in which there is a picture of the 1961 mechanical conversion (out of the package and without any instruction sheet). It shows that in that year both the center and rear throttle shafts were replaced. The picture does not show any light throttle shaft springs but not to say they weren't included and just not pictured. The triangular plate looks different than that in 541158 drawing as posted by John V. earlier in this thread. I don't see why the center shaft was replaced but that's what the story says. I have the story in PDF and don't know if it will attach to this post so it can be opened.

|

|

#63

|

||||

|

||||

|

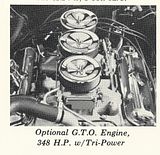

I don't know if this is significant or not, but it appears Pontiac was toying with the idea of mechanical linkage for the 64 GTO very early. This photo is from page C-9 of the Sales Manual. It was part of release #4 along with #5, #6, and #7 which occurred sometime between Oct. 21, 1963 (release #3) and Nov. 20, 1963 (release 8). Release 4 though 7 is not dated.

|

|

#64

|

||||

|

||||

|

That's the first I've noticed this picture. Can't tell if the "other lever" is the same as the one we've been discussing, or just similar. I believe it's just similar since the top of the extension is held on by a bolt and nut in what appears to be the very top of the center carb throttle lever. This is not drilled on a normal '64 center carb, just punched to create a protrusion that locates other extensions.

It also appears that the rod from center to rear carb is a slotted rod like the '65/'66, not the rod & tube. Can you see more detail on the original?

__________________

BONESTOCK GOATS '64 GTO Tripower Hardtop (Wife's Car) '64 GTO Tripower Post Coupe (My Car) '99 Bonneville SE Sedan |

|

#65

|

||||

|

||||

|

Not really, The picture is only about 2" square, but you can zoom in on Photobucket and see it better than in person.

|

|

#66

|

||||

|

||||

|

I can ZOOM IN and can clearly see that it is a Tube and Plunger style linkage and that it is NOT a "Curved Linkage" set-up.

They even have the Tube and Plunger installed correctly on this photo. Tom Vaught

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#67

|

|||

|

|||

|

Chad, I think that pic is kinda significant.

I have also interpreted that Pontiac intended to have an option for mechanical liinkage in '64. I've mentioned it before, the original version of the 8 page GTO Sales Brochure mentions "mechanical linkage" as one of the performance options. It wasn't until the April 17, 1964 revision of that brochure where the parenthetical "(dealer installed)" was added to this item. My interpretation is that they DID think about offering mechanical linkage as an option but never got it done for '64. We're left to wonder why they failed to make it a factory option in '64. Possibly because it would have added some build "complexity" to choose between 2 different set-ups. They sorta solved that issue for '65 by offering just one set-up depending on trans. Or maybe they just had trouble getting the mechanical linkage to work the way they wanted it to until they figured it was too late to make it "factory". But given the Sales Brochure mention and this obviously early pic, it seems very likely that they were at least "developing" the idea of factory mechanical linkage for the GTO. Keep in mind, to that point, they had ALWAYS used the Vac setup on the big cars and only offered the mech linkage as a dealer accessory. Only exception may have been the factory SD cars, but I'm not sure even they would have gotten factory mech linkage. Turned out we had to wait til '65 to get the factory mech linkage in a GTO. |

|

#68

|

||||

|

||||

|

Can't see much detail but another example of a 64 Tri-Power with this linkage installed. Early car with 1st design double pulleys and blank valve cover.

|

|

#69

|

||||

|

||||

|

Quote:

Here's how I understand your description of the center carb throttle cable stud from your post. The only change I made is the overall length and actual cable attachment stud. Note the spacer shown on the same drawing. Is the spacer threaded or does it just slide over the threaded portion of the stud? Thanks a lot for the info--especially the Christmas present! Dick Boneske

__________________

BONESTOCK GOATS '64 GTO Tripower Hardtop (Wife's Car) '64 GTO Tripower Post Coupe (My Car) '99 Bonneville SE Sedan |

|

#70

|

||||

|

||||

|

Dick, My STUD Cotter Pin Portion length is .400" (Not .375" long as in your drawing)

My STUD Hex Portion is .870" (not .875" as in your drawing) My STUD Threaded Section matches your drawing. The Stud "Spacer" is not threaded and on further precise measurement is not 5/16" hex stock (as I quickly measured and thought it was) but is 11/32" Hex Stock. The Spacer slides over the threads vs threading on the threads. Tom Vaught pm reply to your note.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#71

|

||||

|

||||

|

65 2+2 421 Tri-Power Auto car.

|

|

#72

|

||||

|

||||

|

Thanks 60sstuff, Now I have seen TWO of the Big Car Curved Linkages. (:>)

The one I have in a box and this photo. Tom Vaught

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#73

|

|||

|

|||

|

In comparing the 64 GTO and 65 421 pics I notice that the 64 uses a throttle cable and the 65 uses a rod. Are thes correct?

I thought that perhaps the 65 has a center carb (and linkage) from an earlier car. That still leaves me to ask why my 66 (big center) carb has the mystery curved lever. Of course, it has been 45+ years and people started mix-and-matching components of the tripower stuff from day one so it is difficult to trace the pedigree of any particular unit. So, now, counting my curved lever, how many of them are known today? |

|

#74

|

|||

|

|||

|

Dicks drawing of the stud and spacer for the curved extension closely depics Tom`s dimentions however the threaded end seems to come up short. The length needed to attach the stud with a nut would not have adequate thead exposed. I measure the curve bracket at .124 thick, the existing carburetor throttle lever at .138 and the spacer that Tom gives at 5/16". That should total only .176 exposed thread and just a common 1/4" nut is .220-.225. Dick is that what you have found??

Also from the 60`s stuff latest picture, the throttle lever reaches towards the carb just as the factory drawing I have. The GTO cable would also have to reach to the right, and not run straight like the 65 J strap. Possibly not a problem but why do it as a slightly longer stud would fix everything? |

|

#75

|

|||

|

|||

|

Doug I did not see you post. How long are the threads on your throttle stud?

|

|

#76

|

||||

|

||||

|

Quote:

Another Big Car 421 Tri-Power showing the throttle "rod". This car is still has the factory Vacuum Linkage. |

|

#77

|

||||

|

||||

|

The '65 "J" strap required a longer throttle cable stud than the '64 GTO needed. The '64 GTO used a short one (hex portion 9/16"), the '65 used a longer stud (hex portion 1 1/16"). Those lengths match the cable attachment point with the throttle cable tower offset--unless the Tripowers and car years are mix 'n match.

For the big Pontiacs with a throttle rod, the ball stud is exactly 1" long (from the inner end of the hex to the outside face of the ball). Pictures below will explain what I mean.

__________________

BONESTOCK GOATS '64 GTO Tripower Hardtop (Wife's Car) '64 GTO Tripower Post Coupe (My Car) '99 Bonneville SE Sedan |

|

#78

|

||||

|

||||

|

Thanks to War Eagle's post, I rechecked the dimensions of the throttle cable stud and found the threads should be longer than 3/4". The thread length on the stud for the curved center lever extension (drawing in post # 69 above) would work out better if 7/8" long. This results in two threads being exposed on the inside end of the stud when installed. This is with a "correct" castelated 1/4-20 nut, which is thinner than a standard nut.

__________________

BONESTOCK GOATS '64 GTO Tripower Hardtop (Wife's Car) '64 GTO Tripower Post Coupe (My Car) '99 Bonneville SE Sedan |

|

#79

|

||||

|

||||

|

Quote:

You are correct, the curved bracket is ~.125" same as the smooth portion after the hex. My stud has about 2-3 threads showing after the nut. Tom Vaught

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#80

|

||||

|

||||

|

Maybe not My bad.

I looked at my post again and I mention the smooth portion: "Area after Hex but before Threads is .120" (same as extension thickness)", same as War Eagles curved bracket (extension) thickness reported .124" give or take .004" Dick needs to include the "smooth" portion after the hex but before the thread in his drawing, not shown currently. Tom Vaught

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

| Reply |

|

|