| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#41

|

||||

|

||||

|

lookin good!

__________________

Happiness is just a turbocharger away! 960 HP @ 11 psi, 9.70 at 146. Iron heads, iron stock 2 bolt block , stock crank, 9 years haven't even changed a spark plug! selling turbos and turbo related parts since 2005! |

|

#42

|

||||

|

||||

|

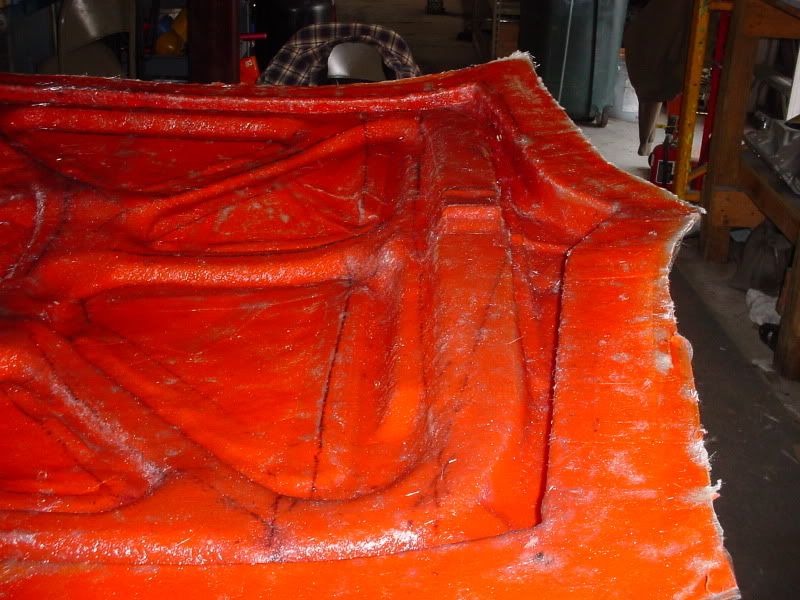

I laid up 4 layers of fiberglass cloth and resin. 2 on the actual frame then 2 more over the whole thing.

Lots of cutting and fitting.   I think I will go in and pull the mold apart tomorrow.

|

|

#43

|

||||

|

||||

|

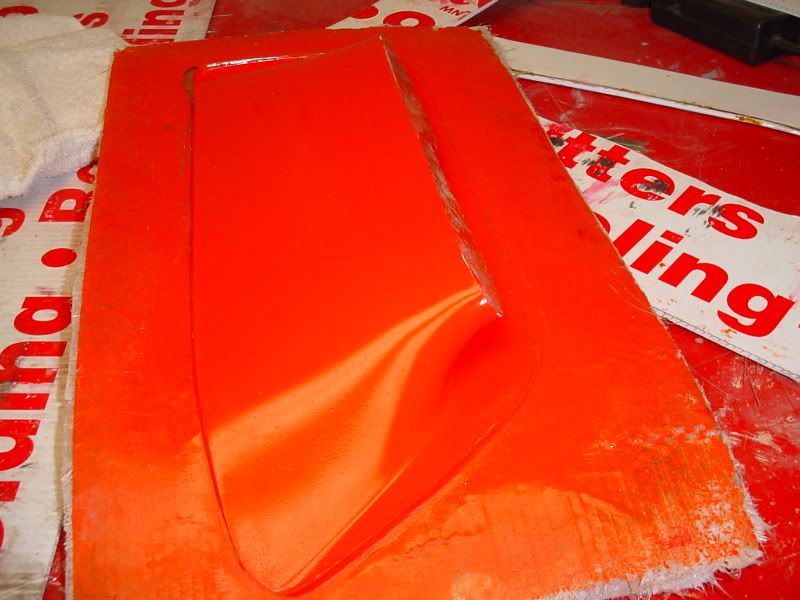

I have a hood mold!!

Frame mold!   Hood skin mold!!

|

|

#44

|

||||

|

||||

|

John-

What's next, start laying CF in molds? Looks great! |

|

#45

|

||||

|

||||

|

I am first laying up a fiberglass hood for practice. then I will do a carbon fiber hood.

|

|

#46

|

||||

|

||||

|

I made the molds for the hood scoops and the other air extractor.

The drivers side scoop mold. I have some minor things to fix.    I will pull the other parts from the molds tomorrow. |

|

#47

|

|||

|

|||

|

John

I wrote to you through the pro-touring site. Something happened to my login information and I couldn't get your message. Since I'm a Pontiac guy this is better anyway. Mark |

|

#48

|

||||

|

||||

|

Two extractor molds and two scoop insert molds.

Test fitting some carbon fiber.

|

|

#49

|

||||

|

||||

|

The first part, a driver side scoop insert. The white on the edges is air pockets from not getting my carbon cloth tucked in far enough and not vacuum bagging the part. I can fix the air pockets and I will sell this part as a part that needs to be painted. I think I have just made the best fitting 69 T/A scoop inserts. Monday I will get the vacuum bagging stuff and I hope by the end of next week I have a bunch of nice looking carbon parts.

|

|

#50

|

||||

|

||||

|

Awesome!!

|

|

#51

|

||||

|

||||

|

Hats off to you for taking this project on. You stuck it out and "got er done"!

It was one of the more interesting threads on here in a long time. From what I see regarding your quality concerns you strive for, you should do very well marketing these. Did the original steel hood come out AOK from the layup process? That took some guts based on what they sell for OEM. Best with sales & marketing..... Jeff |

|

#52

|

||||

|

||||

|

NICE!

__________________

Have some fun while ya still can !

|

|

#53

|

|||

|

|||

|

Nice work John!!

|

|

#54

|

||||

|

||||

|

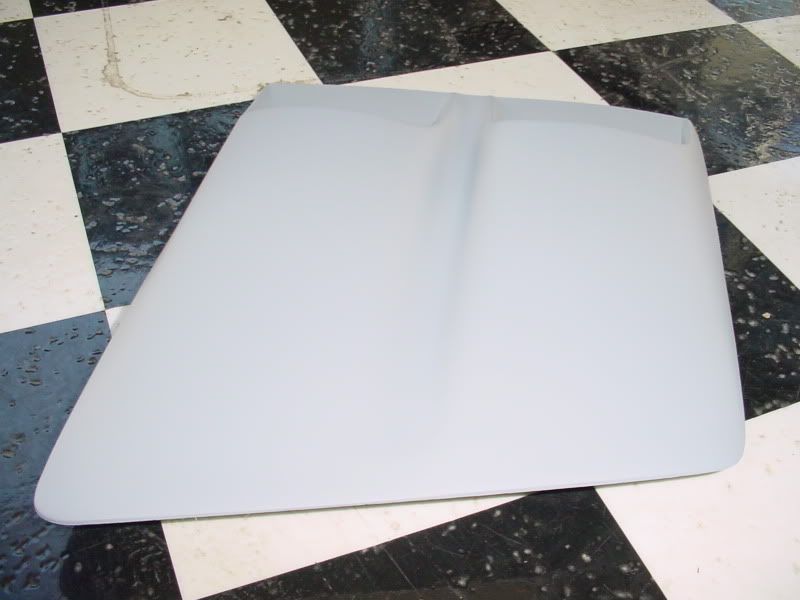

Some fiberglass side air extractors.

I had some problems with the clear gelcoat in these molds so I made them in fiberglass.     I also made the other hood scoop insert, It is nicer than the other one but I still had some air pocket problems. I fixed and preped the first one for paint, all it needs now are studs to mount it and paint. It fits perfect.  I am getting better and as soon as I can get these small parts perfect, I will lay up the hood. |

|

#55

|

||||

|

||||

|

What is your method of attaching the studs?

|

|

#56

|

||||

|

||||

|

very nice work.

Looks like it would really help out some of the FAST guys save some weight off the front end. Maybe get a poncho into the ten second club!

__________________

Happiness is just a turbocharger away! 960 HP @ 11 psi, 9.70 at 146. Iron heads, iron stock 2 bolt block , stock crank, 9 years haven't even changed a spark plug! selling turbos and turbo related parts since 2005! |

|

#57

|

|||

|

|||

|

I have a question

I am running twing turbos and with the under hood heat the hood its self gets very hot, I have insulation under the hood to help keep the heat off the hood. My question is how is Carbon Fiber with heat? Can it take more heat then Fiberglass?

__________________

68 400 Firebird Convertible TH400 Solar Red 69 Firebird Convertible Pro Touring Twin Turbo 5 Spd 70 T/A RA III 4 Spd 3:73 Calif Emissions Lucerne Blue 74 T/A SD-455 TH400 Buccaneer Red 49.600 Mile Survivor |

|

#58

|

|||

|

|||

|

Quote:

Sometimes they discolor, or turn 'white-ish', but usually return to their normal color after they cool off. I've never had one warp or separate. Hope that helps. On a side note, I also have a PT '69 Firebird, only a coupe. I am pretty much done, but I haven't had the time to post the build up on Lat-g or PT.com yet. Do you have a build thread going anywhere, I'm curious to see what you've done. Josh |

|

#59

|

|||

|

|||

|

Quote:

Thanks for the info, looks like i definately want to be on the list for one of the Carbon Fiber hoods My bird is pretty much done (atleast till i find the next goodie to purchase for her) I have not posted a build thread or even put up any pics of her yet Hopefully i will post up some info on her soon, when i do i will let you know Again thanks for the info Bob

__________________

68 400 Firebird Convertible TH400 Solar Red 69 Firebird Convertible Pro Touring Twin Turbo 5 Spd 70 T/A RA III 4 Spd 3:73 Calif Emissions Lucerne Blue 74 T/A SD-455 TH400 Buccaneer Red 49.600 Mile Survivor |

|

#60

|

||||

|

||||

|

I trimmed, installed studs and primered this pair of fiberglass side air extractors. They will need very little work to be ready for paint. I am going to sell this set.

|

| Reply |

|

|