| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

|

| Pontiac - Boost Turbo, supercharged, Nitrous, EFI & other Power Adders discussed here. |

| Reply |

|

|

Thread Tools | Display Modes |

|

|

| Pontiac - Boost Turbo, supercharged, Nitrous, EFI & other Power Adders discussed here. |

| Reply |

|

|

Thread Tools | Display Modes |

|

#61

|

|||

|

|||

|

Quote:

Fill is said to reinforce cylinder walls for better ring seal... IMO it would work BEST if block and mix, when you pour it, were both at same temp as the engine operates. Again IMO not worth it unless you have marginal thickness cylinder walls. Excellent harmonic control which also includes safe detonation free tune is biggest key to durability in any engine. |

|

#62

|

|||

|

|||

|

A number of people have boosted pontiacs at or above 800 hp, and lived a long time. Theyre around here, but a few of them dont post a lot. I think the key to longevity revolves around 2 key points.

1) An RPM limit that relies on torque peak somewhere in the high 4000's to early 5000's (in other words NOT using a cam designed to make peak power at 8000 rpm). Its been said by Tom and others, and I agree completely that the stress of adding more boost is far less easier on the block and rotating components than swinging all that weight faster. 2) keeping the tune safe and avoiding detonation, lean conditions, etc. This is where EFI really shines because while you're busy putting the pedal down the computer can watch for something going wrong and pull ignition timing if necessary or even cut ignition. Then there are added safety things like water/meth injection under boost that can add to the safety margin. |

|

#63

|

||||

|

||||

|

Its true about the rpm's. My motor lived for 4 years straight at 30 psi, revving it to 6200 ALWAYS. As soon as I started shifting it @ 7000 - 7200 I cracked the crank. The first time I cracked it I felt it was just because it was too much boost , so I rebuilt it and 2 weeks later had another cracked crankshaft spinning it to 7000 again. After rebuilding it again and lowering the rpm's back down I started adding more boost at 6200 - 6500 rpm's and it lived so I turned it up even more to where I was finally at 42 - 44 psi and the motor held it no problem. Then I had a cylinder let go and cracked 6 months later so I pulled it , all the bearings still looked new. I took the crank down to get magged and it checked out fine with no cracks. So if you ask me from my own experience its rpm that kills not boost , an I don't run the quarter i run it out for a mile, So there is a lot of dwell time with the rpms in my case of use... But I do only have a 3.75 stroke so maybe this helped my scenario ..

__________________

My Half AN Injun..... |

|

#64

|

||||

|

||||

|

I'm at 960 hp on a factory '59 389 block, no problems to date. It is 3/4 filled and I'm on a pretty safe tune, 7000rpm and 18psi so far. I'm confident it will hold to the 1200hp mark.

|

|

#65

|

||||

|

||||

|

Most of the smart people (including George) have figured out that you can have a very durable boosted engine if you get a few things right. Compression ratio vs fuel, ignition timing, proper air/fuel numbers, etc.

HO Racing was one of the first to publish charts about Connecting Rod loading and RPM vs in their old manuals. 1200 HP was done a lot with the Ford "Renegade" class Centrifugal Supercharger guys who probably never saw really high blower rpm numbers (55,000-65000 rpm type numbers) Nothing like a Turbo charger can achieve. Get a Boosting device that can feed the engine properly and make a decent level of boost durably and have some fun. Luhn one time made 863 at barely 5300 rpm and 14 psi. Tom V.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#66

|

||||

|

||||

|

Quote:

GTO George |

|

#67

|

||||

|

||||

|

Do the older blocks bolt into our cars without issue?

|

|

#68

|

||||

|

||||

|

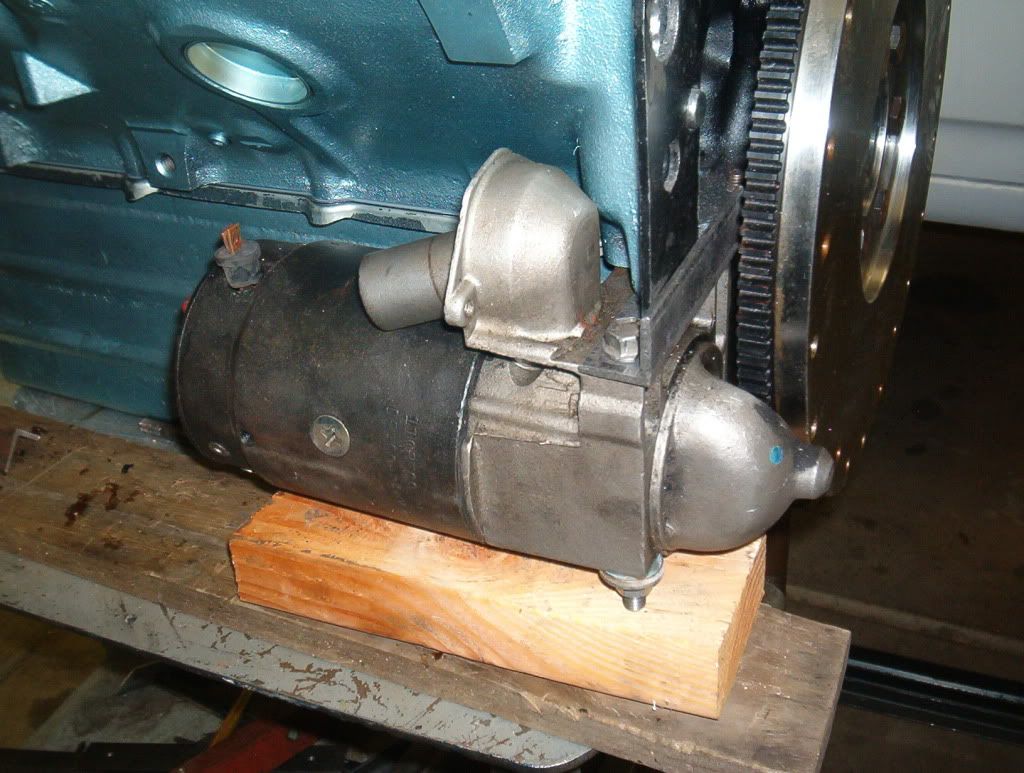

Older Blocks require a Front Plate usually unless you are talking 389 cid and up.

Older blocks also require a mount for the starter vs a provision being cast on to the block for the starter (64 and later blocks have the block mount deal). Tom V.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#69

|

||||

|

||||

|

1955-1960 all have the early bell housing pattern which is a small diameter pattern, even the locating dowels are narrower compared to the 1961 and up. The 55-60 rear bell housing face is also about 1/4 inch shorter than the 61 and up patterns. Because the 55-60 pattern is narrower, the block flange at the rear of the block (the flange that the later blocks are drilled and tapped for the later starters) does not extend out far enough to even drill and tap the outside starter bolt holes. 55-58 blocks do not have the side mount bosses for motor mounts so front plates are usually an answer. The 55-58 front motor mounts originally used the bottom of the timing cover for the front mount. 1959 blocks started with the side mount bosses. The early 55-60 blocks were much thicker and I believe a higher nickel content also. Even the lifter bore bosses are thicker which helps with the quicker lift roller cams that can take out the later lifter bores. The thought that the bores can be bored so much more comes from the fact that the original bores were small. The biggest was 4.060 of the 389. When you start boring them they can go up to a 4.150-4.180 pretty comfortably but anything bigger should be sonic tested for core shift. I bored my '60 block .090 to 4.150 but it tested out thicker. I just wanted to have a thicker wall for forced induction and to have something to bore out to incase I did any damage to the walls.

__________________

My Gasser '63 Catalina build. Oh sorry, it's a Street freak. Either way it's a fun build. |

|

#70

|

||||

|

||||

|

Mark are you using a 59 block in the build that you are currently building now ?

__________________

My Half AN Injun..... |

|

#71

|

|||

|

|||

|

yes he is

|

|

#72

|

||||

|

||||

|

Actually it's a '60 block. But there are only two changes from the '59 to the '60 blocks that I know of. The '59 had an extra set of water jacket holes in the front of the blocks to accommodate the reverse cooling pumps. The '60 went to the block then heads cooling and the extra holes in the front are not there. I think the block deck holes are also drilled differently on the '60 block from the '59 block to promote water flow to the rear of the block. Although that may have been on later blocks as they found cooling issues after the change. But the basic blocks are the same. Extra metal throughout the block, extra ridge inside the crankcase, more nickel in the mix, and the early smaller bell housing pattern. I had to make my own pattern adapter.

__________________

My Gasser '63 Catalina build. Oh sorry, it's a Street freak. Either way it's a fun build. |

|

#73

|

||||

|

||||

|

Quote:

__________________

My Half AN Injun..... |

|

#74

|

||||

|

||||

|

I used one of the 1/8th inch Pontiac to Chevy pattern plates/adaptors that have been out for many years. I then used the mid plate from Indian Adventures (IA) that is also 1/8th inch to make up the full 1/4 inch difference in the early pattern block to the later block depth. I had to drill the two out for the early pattern. Including the locating dowels. Once I had it all drilled and the dowels all located I bolted the two plates to the early block, installed a manual flywheel (because I intended to run a manual first) and mocked up a factory HD Pontiac starter to line up to the flywheel. This placed only the inside bolt on the block flange because the early block flange is narrower than later blocks. Leaving the outside bolt hole out in the air. I used a piece of 1 inch angle iron and placed it up against the flange, located starter up against the flange and in appropriate location for the flywheel, and marked, drilled and tapped the angle iron and up into the block flange. If you're with me so far, the angle iron was mounted with the inside against the flange and the angle up into the bell housing cavity, not pointing down, because it would interfere with the starter mounting base/nose. The angle iron now is sticking out beyond the end of the block flange enough to located, drill, and tap a hole for the outside starter bolt. I also tacked in a top 9/16 nut for the bolt giving it more strength than the angle iron flange thickness.

While doing all of this with the angle iron the one 1/8th inch Pontiac to Chevy adaptor was bolted to the block, the angle iron was again overlaps the one adaptor and is welded in place to that adaptor. This locates the angle iron with the adaptor so it lines up with the starter location every time. Next I had to cut out a small piece of the 1/8th inch IA mid plate around the angle so it would lay flat against the other plate. This is the adaptor plate bolted to the block, the starter mocked in place and the angle iron located but not yet welded to the plate.  This is just another angle.  This is the IA mid plate installed and cut out for the starter but not cut out for the angle yet.  Another angle of that picture. The IA mid plate still not cut out yet.  The angle iron was shortened appropriately and welded to the black adaptor plate. So far it has turned the motor over several different times while I was wiring the car. But I have not tried a sustained turn over since I'm not ready to start he motor yet.

__________________

My Gasser '63 Catalina build. Oh sorry, it's a Street freak. Either way it's a fun build. |

|

#75

|

||||

|

||||

|

This is the finished set up.

First is the adaptor plate, next is the IA mid plate, because I was using a blow proof bell housing, the block saver plate, then the bell housing. At this point the housing was all aligned, clutch all in stalled, and hydraulic throw out to be measured, adjusted for depth and ready to have the trans installed.  Trans installed.  Mark

__________________

My Gasser '63 Catalina build. Oh sorry, it's a Street freak. Either way it's a fun build. |

|

#76

|

||||

|

||||

|

Some really nice fabricating to allow the later starter to be used with the earlier 60 block.

Great Job, as usual. Tom V.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#77

|

||||

|

||||

|

Quote:

http://jalopnik.com/5379917/worlds-f...d-speed-record http://www.autoblog.com/2009/10/12/v...ld-record-for/

__________________

__________________________________________ "How I learned to stop worrying and love the OHC Pontiac L6"  The Silver Buick- '77 Skylark coupe w/455, SPX, MegaSquirt 3 & TKO-600 (Drag Week 2011, 2012 & 2015!) 1969 Firebird with a turbo'd Pontiac L6 controlled by a MegaSquirt 3 and backed with a microsquirt controlled 4L60e and 4.56 gears! (Drag Week 2018!) |

|

#78

|

||||

|

||||

|

Thank you Tom, coming from your background and expertise I appreciate it.

Mark

__________________

My Gasser '63 Catalina build. Oh sorry, it's a Street freak. Either way it's a fun build. |

|

#79

|

||||

|

||||

|

Quote:

Thank you for posting your pictures . I'm looking at getting a 59 block so I will be making a adapter soon.

__________________

My Half AN Injun..... |

|

#80

|

||||

|

||||

|

Quote:

__________________

My Half AN Injun..... |

| Reply |

|

|