| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#281

|

|||

|

|||

|

Quote:

The cornering lights need to be addressed now. I have to decide if I am going to run with or without cornering lights now. I currently have one fender cut for cornering lights and the other is not. I need to either fill one hole or cut another hole on the other fender and soon, since I hope to finish prep on the fenders by the end of next week. Hopefully my Rivera cornering lights will arrive in a few days and I can decide if they are usable. Quote:

Quote:

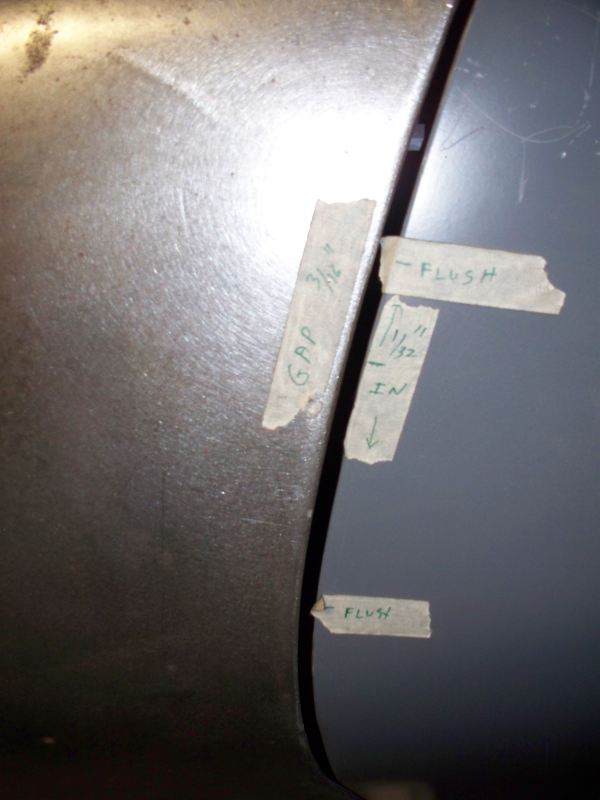

The misalignment is 1/32" and covers a smaller area than the other side. Probably as good as it gets for factory standards.  The gap does grow a little at the top of the door but is off no more than other cars I see.  I'm now trying to decide if I should break down and rework this door like I did the passenger side. This side is probably up to factory standards but may stand out as bad when compared with the passenger side. As to work on the car, mostly more of the same, filling and sanding the problem areas. Mostly complete except for a couple of pin holes. Maybe a little more blending right before I shoot more primer over the work.  Another coat of filler at the front of the door. The level is close but not quite high enough.  I started on the driver door today. Roughed up primer before applying filler.  And the first coat of filler.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#282

|

|||

|

|||

|

Not much new going on still working problem areas. However the passenger door to quarter filling is totally complete.

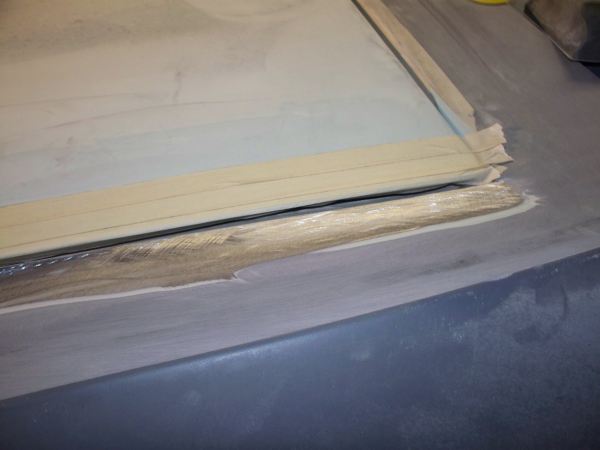

I thought I would outline the steps I followed since this is a little different from filling a slight depression. I find it is much harder to build up a surface as opposed to filling in a dent. For the first two to three filling sessions I tape up the quarter and jam area since I don't want any filler on the quarter. I use quarter panel as a guide, dragging one edge of the spreader across the quarter panel to set the contour on the door. In my case I took three attempts to get the level built up high enough. For these filling sessions I used regular Rage. I kept the door edge square and waited until everything was finished before rounding the edge slightly. For the Last coat I used Rage Extreme. For this last filling I opened the door at applied a light coating dragging the spreader fairly hard since I only wanted a thin coating for the last coat. After sanding the filler fairly smooth I applied a guide coat and continued sanding until all of the guide coat disappeared. My last sanding was done with 320 grit to feather the edges. This is the end result. I am showing this in slightly higher resolution to give a better view of the result. A few comments since photos often lie and things aren't as the appear in the photo. 1 - The result is extremely smooth and no ripples can be felt with you hand. The dark spot at the very top is where I sanded through the Rage Extreme and uncovered Regular Rage which is a slightly different color. 2- The two blue spots are where I fixed a couple of pin hole problems. For this I used Easy Sand, which is a spot filler. 3 - Because of shadows and the slight sanding on the edge of the quarter the gap looks uneven. It's much better than it appears in the photo.  On the driver side I am almost complete I have one area that is slightly depressed near the edge. The black in the hole is the guide coat. You can still see that the edge it completely square. I find that rounding the edge should be the last step.  Passenger door is almost complete. I messed up the lower part of the door by sanding where it didn't need sanding and had to run filler farther down.  This work is slow, although the instructions talk about being able to sand in 30 minutes, I find that sanding seems to work a little better if you wait somewhat longer. I usually wait 60 to 90 minutes before sanding.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#283

|

|||

|

|||

|

I have not been able to work on the car too much lately, I usually have Tuesday and Thursday off, but have been too busy at work to take the days off. I still have been trying to work for a couple of hours per night to move things along.

I have reinstalled the trunk lid so I can make the edges flush. The back edge varies form being flush to being depressed by about 1/16". I applied several coats of Rage to build the edge even.  The edge is nice and flush now.  This is still a work in progress. I still need to sand entire lid smooth and apply a very thin final coat of Rage Extreme over the entire deck lid, followed by one final sanding.  My Rivera Cornering lights came in. They look like they should work. They are a little bigger than the Pontiac lights, but not that much bigger. I made a template out of card stock to mark the hole for the lights. It took me several attempts and about 30 minutes to make this pattern.  It fits real tight and will provide a good pattern for the new hole.  I started on the driver door to fender gap problems. My original alignment compromised the gap at the top of the door to get the panel alignment better in the middle. Since I going to use filler to address the middle of the door problem, I readjusted the door so than the alignment was flush at the top of the door. This made the gap much better, however the middle of the door is now depressed by about 1/16 instead of 1/32".  The bottom of the door however is still bad. The contour on the fender patch simply does not match the door. Since this requires around 3/16" of filling at the deepest point, I'm using "All Metal" to do the initial filling. This is the first coat. I used a total of three coats to get to this point. This is close enough to do the final filler work with Rage Extreme.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#284

|

||||

|

||||

|

fbrown did you go on holiday break?

|

|

#285

|

|||

|

|||

|

Quote:

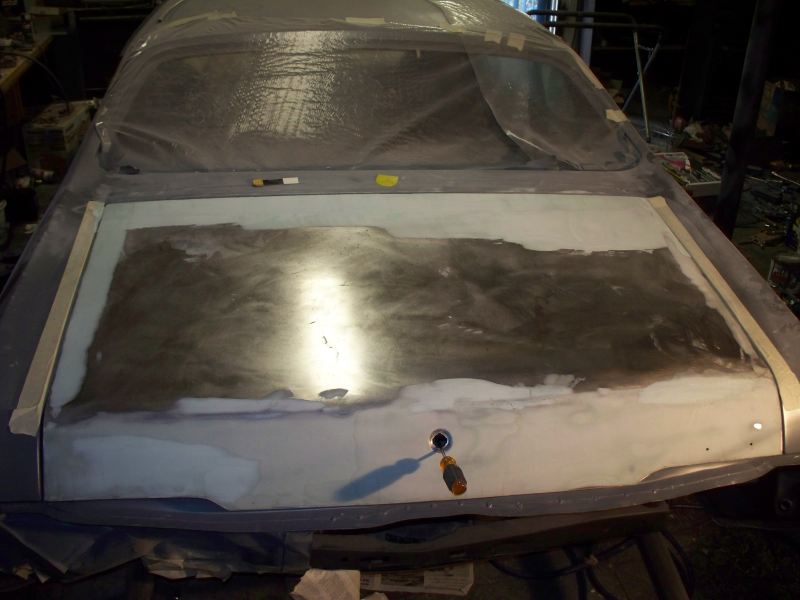

I own 1/2 of a pet furniture business with my girlfriend and while I usually work 3 days a week, I have been working 5 days/week for the last two weeks. While I tried to throw a layer of mud on each night, I started getting home later and later, finally I was simply too exhausted to even throw on a single layer a filler per night. I guess old age is catching up with me. I own 1/2 of a pet furniture business with my girlfriend and while I usually work 3 days a week, I have been working 5 days/week for the last two weeks. While I tried to throw a layer of mud on each night, I started getting home later and later, finally I was simply too exhausted to even throw on a single layer a filler per night. I guess old age is catching up with me.  The good thing is I have 5 days off starting tomorrow night. Here is a few pictures of what little work got done. Trunk lid with dry guide coat applied.  Here is a partial of the filler sanded. I have a long way to go. My biggest problem is I don't seem to be able to apply filler smoothly to large areas. I use a 17" In-line sander then switch to a Dura Block for the final work.  Here are some real problems. A low spot on the left side that needs more filler. Two high spots and what appears to be a small long dent. The high spots I tapped down with a pick hammer before applying the next coat of filler.  I continued sanding the filler to prepare for the next coat of filler. You can see the area around the trunk lock is still low.  Another coating of filler and sanding. Better but not good enough.  Driver fender, almost finished here. Covered the weld seam where the lower fender patch was welded. Also covered the "All Metal" where the contour was off. Also I didn't bring the filler down far enough on the driver door. Sanding produced this sharp edge. I should have brought the filler down another couple of inches.  For comparison this is the before of the door to fender contour problem.  Door edge is almost finished. I brought the filler down a little farther.  The trunk lid passenger side did not line up with the quarter. The edge aligned at the trunk corner but the quarter dipped to about 1/8" below the trunk edge and became flush as approaching the back of the lid. I prepared the quarter for some "All Metal".  Three layers of "All Metal"  Close enough. Next step cover the entire top of the quarter with a layer of Rage Extreme.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#286

|

|||

|

|||

|

Savings tip. Evercoat Easy Sand is private labeled and sold by Finishmaster as SMART Pourable Putty. Part Number SBF 1193. This stuff sells for about $17 a tube. Easy Sand tends to sell for around $35.

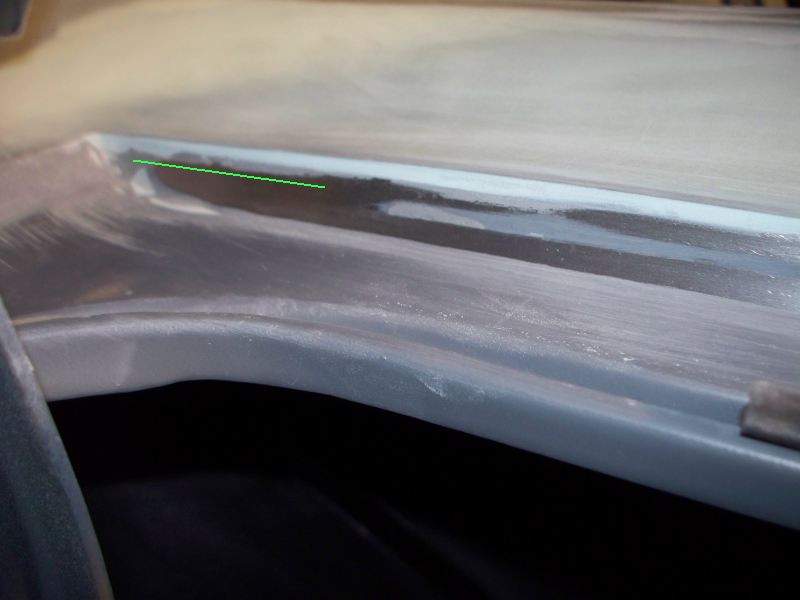

I decided to do one one coat of "All Metal" to the driver side of the quarter before final coating with Rage. There were a few spots that were still a little low.  Unsanded Rage Extreme as applied with plastic spreader.  Once you start custom work, it never ends.  There is only one problem now. The passenger side alignment is too good. I was satisfied with the driver side before fixing the passenger side. The driver side was generally pretty good with a small spot along the quarter that was about 1/16" low. So I guess it's time the fix the driver side. Sand the primer to bare metal so "All Metal" can stick  The first filling of "All Metal" the green line shows where the alignment was out.  The sanded "All Metal" I am very close but still slightly low.  Driver Fender. The front of the fender is distorted and I was unable to get it straighted any better. I filled the front area with "All Metal" and made it match the contour of the bumper. Although generally you should make the bumper match the fender, my fender has obvious flaws, so I will do it backwards and make the fender match the bumper. The maximum depth of "All Metal" is about 1/16"  I removed the fender so I could install my Buick cornering light and cut the core support. Here is the mock up with the fender just sitting in place.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#287

|

|||

|

|||

|

I thought I would talk a little about the trunk/quarter fitment. The filler work I'm doing on the quarters might be due to a slightly bent trunk lid. I did not plan on using my trunk lid since I knew it had been in a wreck. As a result I didn't do much trial fitment and didn't do any checking for panel alignment. There are a great deal of small problems with the Dynacorn panels and it will take some effort to get a great fit and finish, but the filler I'm adding to the quarter panels might not have been necessary with a different trunk lid. In any event had I been aware of the problems sooner I might had dealt with the problems differently. At this late stage with everything installed/welded and primed I elected to deal with the problems by using "All Metal".

My quarter to trunk alignment problems are probably unique to my particular car and not something that would affect most of you. Now, back to the problem at hand. Rage Extreme applied to the passenger quarter. It's smooth and pretty much done. Maybe a little blending with a higher grit sandpaper at the transition to primer, but pretty much done.  The only thing that needs a little touch up is in the trunk gutter area. The area above the green line is slightly low.  On the driver side quarter, I'm done with "All Metal" Ready to be covered with Rage Extreme.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#288

|

|||

|

|||

|

For those wondering what happened to me, I injured my back around new years day moving some trees that fell during one of the recent storms. I have been very sore, and could hardly move. I just now getting over my sore back.

I did manage to get a few things done although in some cases I failed to take photos, sorry about that but some of my work was more for therapy, I needed to move around a bit to keep from getting stiff. I finished the trunk lid and quarter filler work and have a couple of coats of primer on it. I still need a couple of more because I can still faintly see the filler beneath the primer. Trunk lid with guide coat before final sanding of filler.  I failed to take a photo after the final sanding, but here is the trunk lid in primer, I still need a couple of coats to achieve complete hiding of the filler.  Rather than using 1/16" alignment clips that don't like to stay in place, I made a shim from 1/16" stock, I only needed a shim on one side. The other side of the trunk hinge had busted free and I located it so no shims were needed before welding it back.  I still need a couple of more coats of primer on the top of the quarters.  Removed driver fender for filler work, started this last year. You can see a low spot here that still needs more work, the black is the guide coat.  While I don't have a photo of the final filler work, this was taken slightly before I called it quits.  I painted the inside of the trunk with Lizard Skin Ceramic. I will cover this with Dynamat Extreme.  I started prepping to install the gas tank. Installed a connector for the fuel pump and sending unit. I want it easy to drop the tank if necessary. You can also see the rubber mat that was glued to the top of the tank.  I also installed the pigtail for ground for the fuel pump and sending unit. When connecting wires to the frame be sure to remove paint where the connection is. You don't want a bad ground to the fuel pump.  I used heat shrink to cover the bright yellow crimp connector. There are two grounds here, one for the fuel pump and one for the sender. I will paint over this spot on the frame the next time I mix up some black epoxy paint.  My next task will be to install the gas tank, I used a transmission lift to lift the tank into position, I called it quits for the night after finding my bolts for the gas tank straps are too short.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#289

|

|||

|

|||

|

I got the gas tank mounted tonight. The stainless steel straps were a big pain. I had to straighten and reform the rear end part. They were bent too tight and it was impossible to insert the straps in the slot where the bolt is inserted.

After looking at the filler neck its clear that I need to make a bracket to support the filler tube. The rubber hose and two clamps are just not good enough to support the filler tube. The green line shows how I plan to make a bracket for support.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#290

|

|||

|

|||

|

I reinstalled the trunk lid and got the driver door in primer this weekend.

Thanks to Paul at Fast for the tip about sand paper changing to a "p" rating that is courser than the old. I thought that I was having deeper sand paper scratches in my filler work than I though I should when using P320. It looks like I need P500/P600 for final work before laying the base coat. I started some test sanding using P320, the scratches look to large for base coat to fill. The next finer paper I have is the old 600 grit, this turns out to be too big of a grit change. The gaps are now even and the trunk lid lines up well.      Driver side fender primed and ready to be reinstalled.  I shot some primer over the filler work where I made the door even with the fender and quarter.  I found the middle rear bumper support and cleaned and painted it. The bracket had been removed and was in a stack of parts in the trunk of the car. A great deal of these parts were not off of the LeMans.  I installed a power trunk release I had purchased on Ebay, it fits and works manually, I didn't test the power part yet. The part was listed for a Camaro so I wasn't sure it would fit.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#291

|

|||

|

|||

|

I once rented an Escalade on a road trip and was blown away by the performance and fuel economy. Ran into a guy with an alignment shop who had taken a 66 Buick and did a restomod installing an escalade power plant and finishing out the vehicle to a high level. It was a stunning ride with the exceptional performance and fuel economy of the escalade power plant that I knew to be far superior to anything I could have done to my Pontiac. He loved the originality of my pontiac and seeing a pontiac motor under the hood. I loved his choice of taking an not so sexy model car and modifying it to a sophisticated driver that made all the sense in the world to me. Originality has it's place to be sure. Everyone likes to see a car finished to a high level of originality. What you are doing to that lemans is so over the top and so unbelievably top drawer, I can't imagine any sensable person faulting the concept. The finished product will be fine as a frogs hair. Well done.

__________________

1965 Pontiac Lemans Convertible, 1957 Chevy 3600 dump bed, 1968 Ford backhoe.  http://picasaweb.google.com/orchidsk...vyiKGThcblmQE# |

|

#292

|

|||

|

|||

|

Quote:

Unfortunately I keep injuring myself so I have trouble working on the car.  I cut my hand real bad at work, so things have been going slow. I hope to get a few things done this weekend. I cut my hand real bad at work, so things have been going slow. I hope to get a few things done this weekend.I applied a guide coat and started sanding the primer.  After sanding this is the result, I still have several areas to deal with. I guess this is not too bad but shows lots of problem areas that would be wavy without attention.  Now for some close ups of the problem areas. A slight low spot in the front. I don't think the primer is thick enough to sand this out.  I have already sanded to bare metal in 3 places and still have a low spot. I am using a 17" long Dura-Block to sand with.  It's possible these low spots might sand out with hitting metal.  Another low spot, the back edge of the fender is also low, the back edge will require filler.  In spite of the multiple attempts to work this area with filler, I still have low spots.  On the back of the car at the back corner of the trunk I wet sanded the area with 600 grit paper. While this photo does not show the flaws or how smooth the surface is, there are a couple of flaws in this area. When you sight along the surface the primer is starting to show a shine, which also highlights any flaw. I have a little bit of a ridge along the green line. Although it looks fine from above, when you sight along this area it is slightly wavy. I also have a slightly low spot along the red line. To the left of the red line you can still see orange peel in an area that I didn't sand very much. The slight sanding scratches are still the remains of sanding with 320 grit.  As I can tell, it's going to take a lot of work to get a flat paint job. This is my first attempt at doing a near show car paint job.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#293

|

|||

|

|||

|

...really sucks. I blocked for days, then hired a helper and we blocked some more. No where as meticulously as what you are doing but I took it to a point where I was way past exhaustion and called it a day. Turned out just ok. You are already far past anything I did and i think you'll be lightyears ahead of any pro work you'd have done. My experience with so called pros is that they tend to disappoint. Lose stuff. Cut corners. Very frustrating and expensive. What you are doing probably doesn't even exist in the real world of professional body work. You would have to pay about ten bazillion dollars to get that kind of work if it really existed. The materials aren't expensive, it's the time you're putting in. What we all wish we had the time to do. I like it. When it's done send me some nice detailed picks.

__________________

1965 Pontiac Lemans Convertible, 1957 Chevy 3600 dump bed, 1968 Ford backhoe.  http://picasaweb.google.com/orchidsk...vyiKGThcblmQE# |

|

#294

|

|||

|

|||

|

More Fender paint prep this weekend.

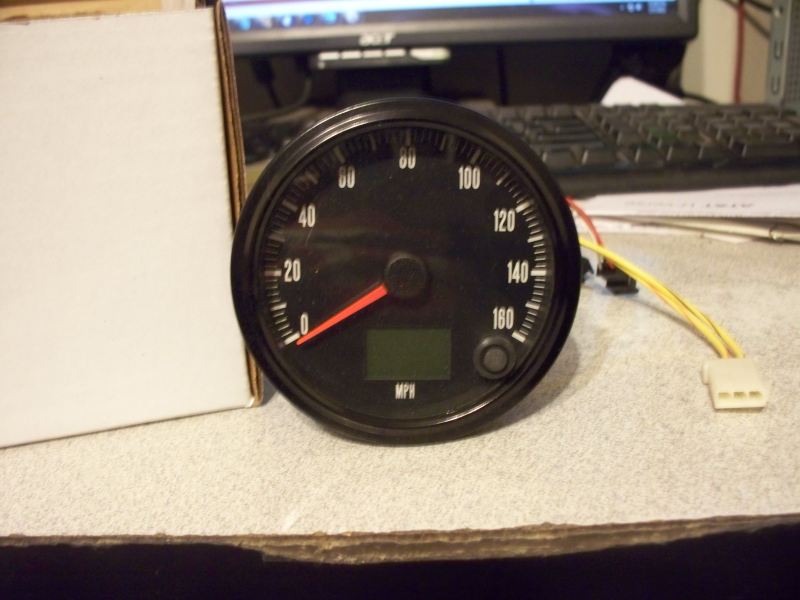

Bad picture and I didn't take another but this still shows what I did. I filled the low spots with a Pourable putty.  I shot four more coats of epoxy primer. I will need to wait a few days before I can sand the primer. The Epoxy primer I'm using needs about 3 days before it can be sanded without clogging sand paper. I hope this takes care of the low spots.  I started reinstalling fuel lines. However the line between the corvette fuel pressure/filter regulator and the engine no longer fit. I ran brake lines while the body was off the frame and installed an adjustable brake proportioning valve. Of course at the time I couldn't tell the adjustable knob was right where the fuel line wanted to go. I had to rework the line and installed some heat reflective sleeving while reworking the line. The black cover is Taylor Heat Sleeving, it is held in place at each end with short pieces of heat shrink.  I working on other things not really worthy of photos. I installed new wiring for the dome light and I'm still reworking the area at the back of the trunk lid. I had a setback with the instrument panel. I was getting ready to apply Eastwood's liquid Chrome to the panel and I dropped it. I now have a crack to repair. Here is the electronic Speedometer I going to use. If I use the mechanical one I will have over $700 in it by the time I get it restored and purchase a Cable-X to drive it. This speedometer will read the VSS signal from the PCM. Best yet it was about $150 on sale.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#295

|

|||

|

|||

|

Fuel line for EFI application and E10.

Most of the available aftermarket flexible fuel line worries me, the description is "resistant to alcohol". This means they slowly deteriorate and would require frequent replacement. The two choices that appear to solve the problem are Teflon coated lines and plastic lines as used by GM and others. Teflon coated lines should last the life of the care but are very expensive. Plastic lines seem to last as long as they are not abused. I made a line to connect from the firewall to the engine using Dorman nylon hose, Taylor heat protective sleeving and quick disconnect fittings. There is a Dorman tool that will press the connectors on the line but it runs about $100 and is expensive for something with limited use. Some people have rigged a caulk gun to press the fittings on. I have a method that works well. I use a 10 ton press to make quick work on the job. This is the materials used. Dorman plastic fuel line, Taylor heat resistant sleeving and the fittings. I also used a couple of short pieces of heat shrink to clean up the look.  This is my setup for pressing the connector ends on. I used the fuel line clamps out of my MasterCool Hydraulic set to hold the line, but a cheap $10 harbor freight flaring tool could be used to hold the line. In my case I used vise grips to hold the clamp on the line. Here the hose and connector are aligned and ready to be pressed on.  When pressing the connector on the barbed end will want to push the hose sideways you can easily guide it with one hand and work the press lever with the other.  This shot shows the hose starting to slide over the barbs.  The final result  At this point I cut a piece of the Taylor sleeving to length. The Taylor sleeving will also protect the nylon fuel line from abrasion.  The competed end with a piece of heat shrink over the Taylor sleeving and barbed end of the quick disconnect.  Now repeat doing the other end. Be sure to slide a piece of heat shrink over the line before pressing the other connector on.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#296

|

|||

|

|||

|

I been working on the valance panel lately. I had previously spent a couple of hours with a hammer and dolly to beat it back into shape. On close inspection I found a couple of hairline cracks that needed attention.

The cracks did not show up on a photo, but this is the repair. I used a copper backing plate in order to apply more heat without blowing holes in the metal.  After grinding and sanding.  I applied Rage as a first coat of filler.  As you can see there is still some high spots and lows.  I knocked the high spot down with a pick hammer before proceeding to apply a layer of Rage Extreme.  I ended up putting another layer of Rage Extreme before I primed the valance. This is the final result of the filler work.  Valance in primer. I applied four coats.  Sanding the primer. This revealed several flaws. These spots were filled withing sanding dust and were not visible until painted. Although I used high pressure air to blow the panel off it did not dislodge the sanding dust. However the paint gun blew this stuff right out.  Flaws filled with spot putty and ready for another coat of primer.  While waiting for primer to dry I started covering the car with Dynamat.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#297

|

||||

|

||||

|

Look'n Great !

|

|

#298

|

|||

|

|||

|

From my last post you may have noticed that I have used both Dynamat Extreme and Eastwood's similar product. While the two products are similar there are differences. Eastwood's is slightly thicker, has a heavier aluminum coating. It also is somewhat heavier than Dynamat. Eastwood's product claims to reduce the heat transfered to the interior while Dynamat does not. Other differences, Dynamat will stretch and conform to odd shaped indentions better/easier than Eastwood's product. I first bought Eastwood's product since it seemed to be priced cheaper than Dynamat but I discovered that Amazon sells Dynamat for about what Eastwood's product sells for on sale.

Eastwood - $119 on sale 33 SQ ft Amazon - Dynamat Extreme $127 36 Sq ft Price however varies day by day. There is no real difference in cost between the two products. If you are only going to install one layer of some sound/heat product, the Eastwood product might have an advantage. In my case I started with Lizard Skin Ceramic, followed by Dynamat or Eastwood's product. I will then cover the Dynamat with a Jute like material with an aluminum backing on one side. For my carpet I am using a carpet made by ACC that has Mass Backing. This should make the car cool and noise free. Now back to Restoration. This is the re-primed valance panel. There are no visible flaws now. A final sanding with P320 followed by P600 should have this panel ready for Base coat.  I started working the problem areas of the bumper. The center at the top of the hood has a larger gap and the passenger side at the top of the fender did not match the fender's contour. First I stripped most of the paint off. Still a little remains, but this is good enough to start the repair process.  The first application of a flexible 2 part epoxy and Sanded.   This is not bad but will require another session or two, before the surface is perfect. The surface needs to be perfect since I don't dare use a spot putty to fix any problems I find after priming.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

|

#299

|

||||

|

||||

|

Any progress?

|

|

#300

|

|||

|

|||

|

I guess I did drop off the planet for a few weeks. I usually have 4 days a week to work on car and suddenly found myself working 6 day weeks. Things have finally settled back down so I can get a little more done on the project. I still managed to get a few things done but didn't take too many pictures or have any time to post them.

I received a PM from Craig asking about vent window setup. I think the response would be of benefit to all, so I will post the response here in the next couple of days. Quote:

Here is a close up to the build up bumper edge. The contour of the bumper did not match the fender at the top. I used 3M 5895 Plastic Repair. Most of the products listed in older Bumper refinishing articles are no longer available so I picked this as the one I thought was best of the available products. A week or so after I started the repair Paul@Fast listed this as the product he uses so it should be good product for the purpose.  Sort of mocked up for test fit purposes.  In between waiting for filler to dry and when I only had a few spare minutes, I worked on the trunk. Dynamat not completely installed but getting there.

__________________

68 Lemans - GTO appearance LS3 68 Eldorado - waiting for restoration 96 Roadmaster Wagon 2014 Infiniti Q50S Hybrid Marietta GA |

| Reply |

|

|