Its been awhile so it is time for an update.

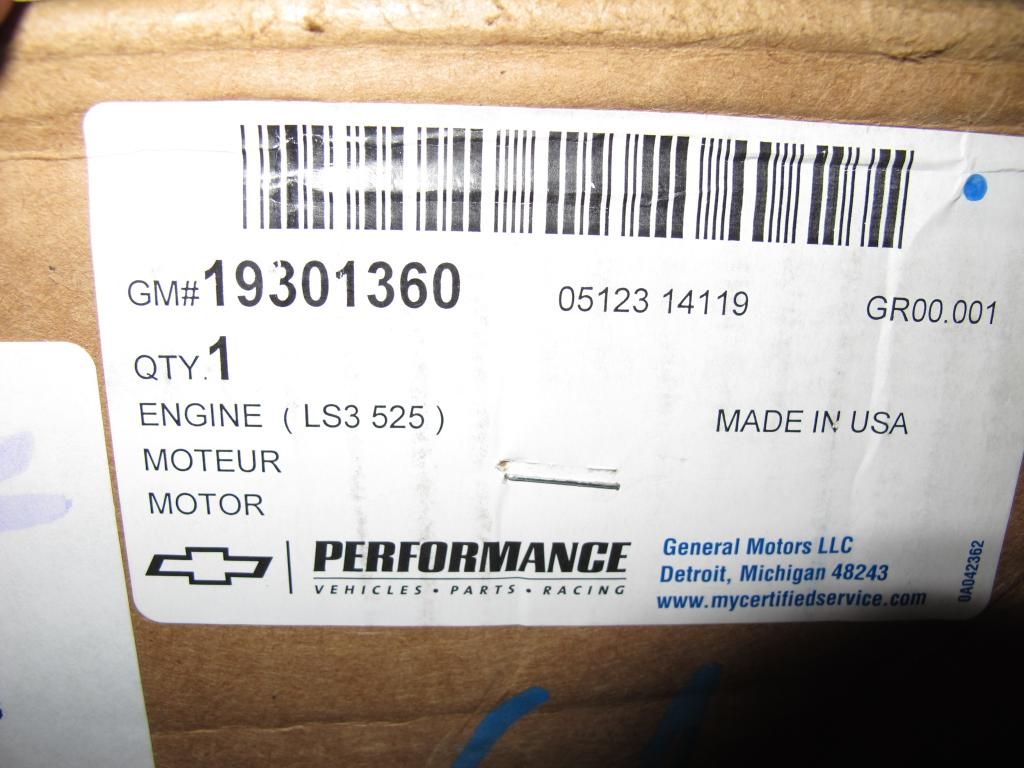

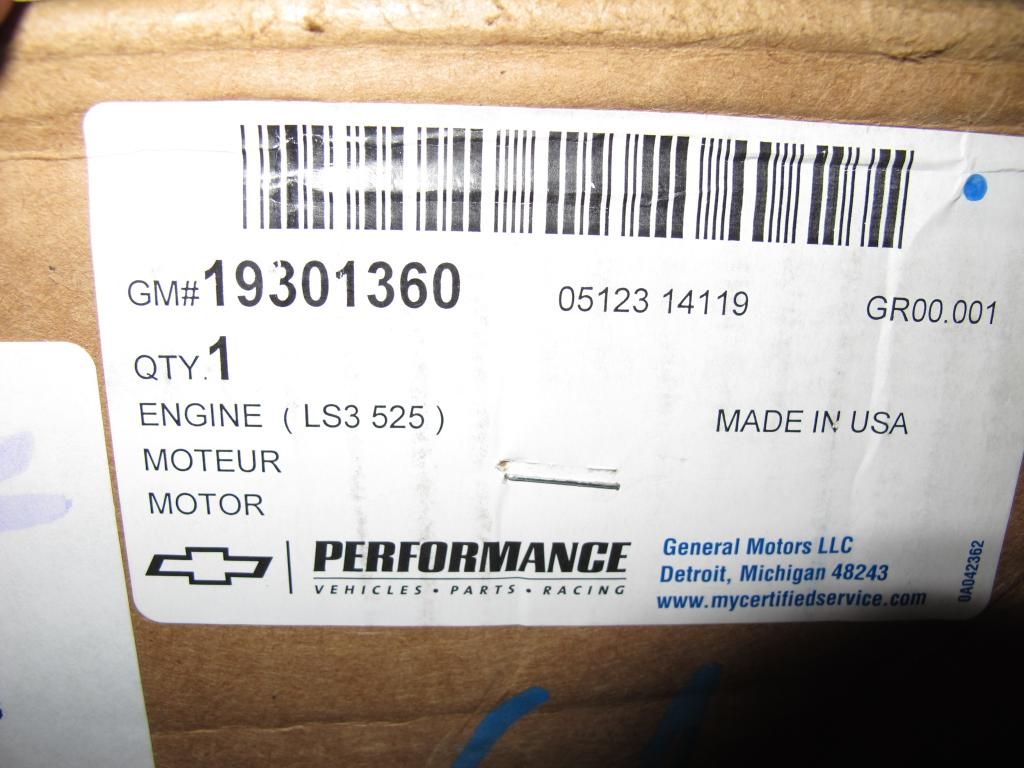

I bought the LS3 525 HP engine from Gandrud in Green Bay, WI at the beginning of October. Nice guys and they price matched Pace Performance and delivered right to my door. I bought the engine, drive accessories, flywheel, clutch and fasteners.

Not a very pretty engine, but this thing ought to make this bucket of bolts haul. Brand new, full warranty and a butt load of potential.

Engine stuffed in the car. Not bad. Notice that I am prototyping a set of Ultimate Headers shorties. More on that to come.

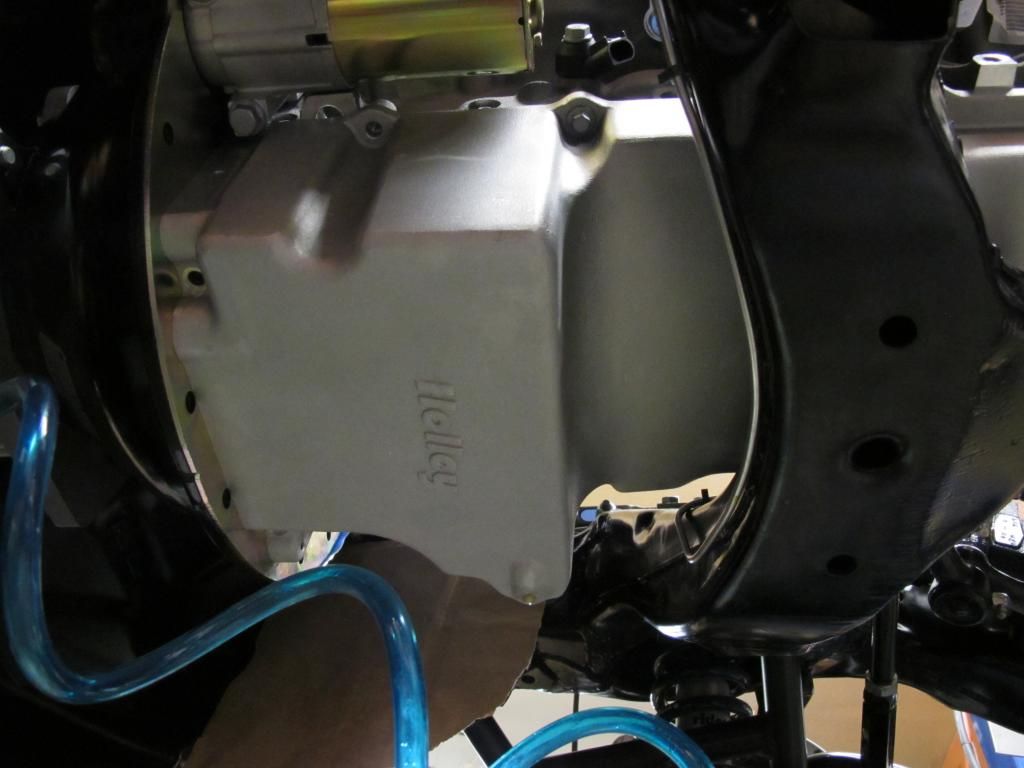

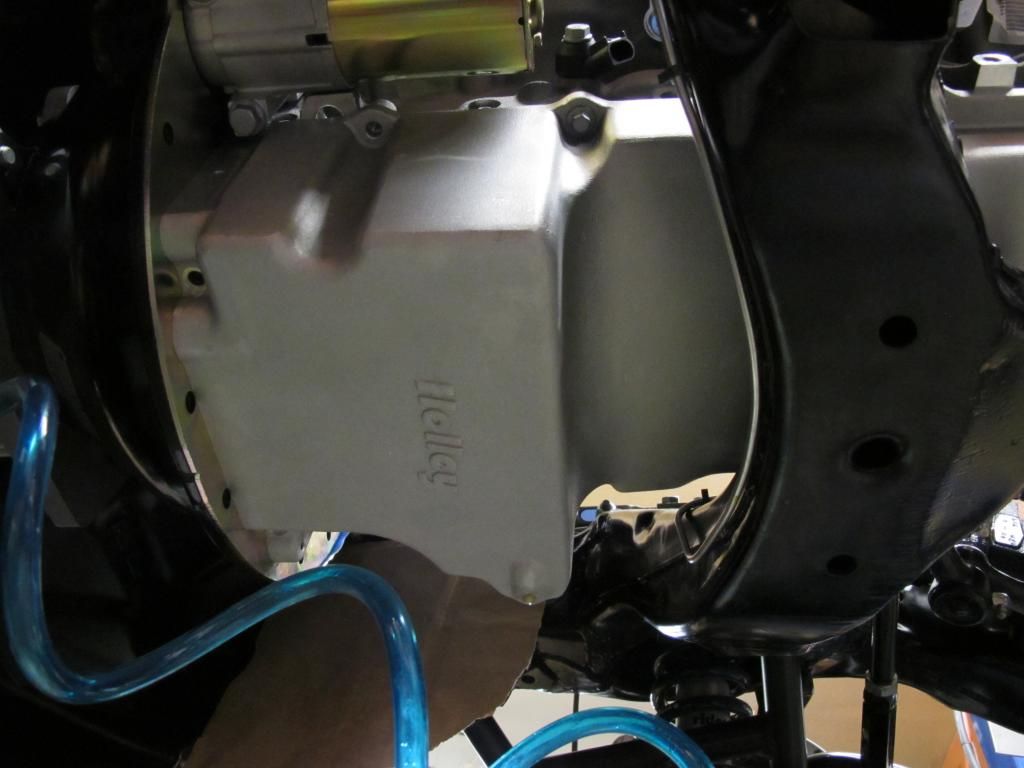

I played around with the Holley 302-2 pan for a bit and I had excellent clearance in the front of the pan. I didn't like the lack of clearance between the back side of the frame and when I spun the motor over without a gasket, I noticed a little incidental contact between the pan and one of the rods. I would assume that the 1/8" thick oil pan gasket would take care of this, but I opted for the 302-1 pan instead

I can keep the full length windage tray with the 302-1 and it is a better casting overall. The 302-2 casting was not nearly as nice as the 302-1. I have about 1/4" clearance before the gasket and should have better than 1/8" with the gasket.

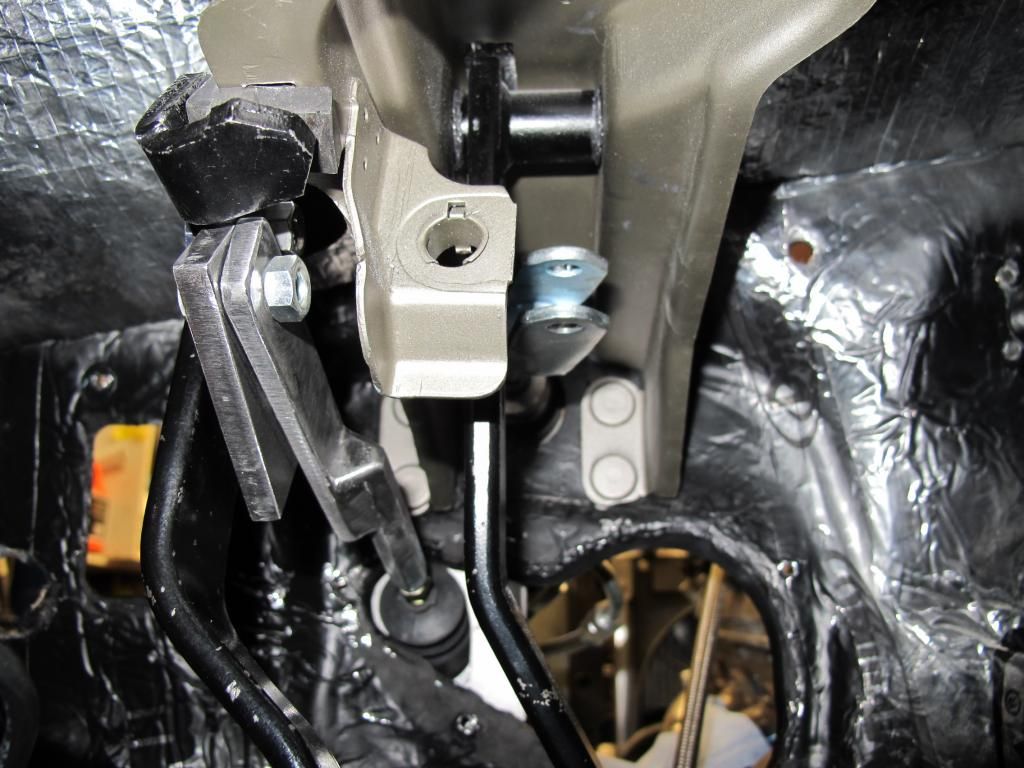

Tie rod clearance that is acceptable for my application. The Ridetech arms limit a tight radius. Even if I had more tire turning radius, I think I would be OK to a point.

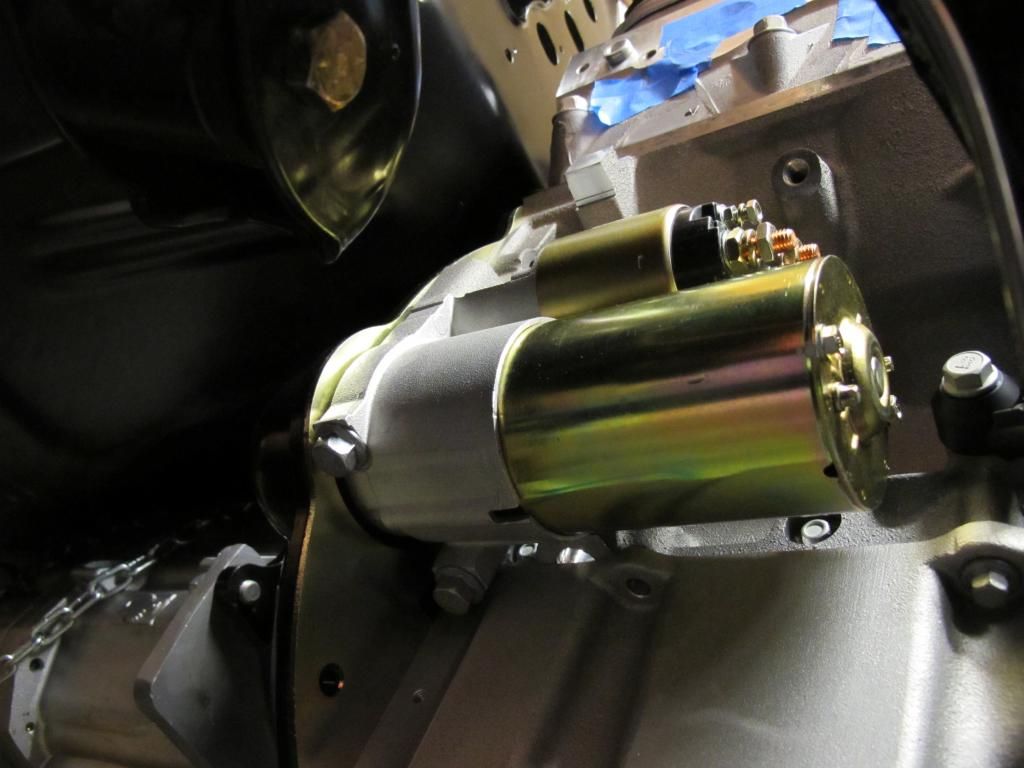

Note the Lakewood scattershield that I am using with my LGT-700. Sourced from Bowler Performance. More on that later.

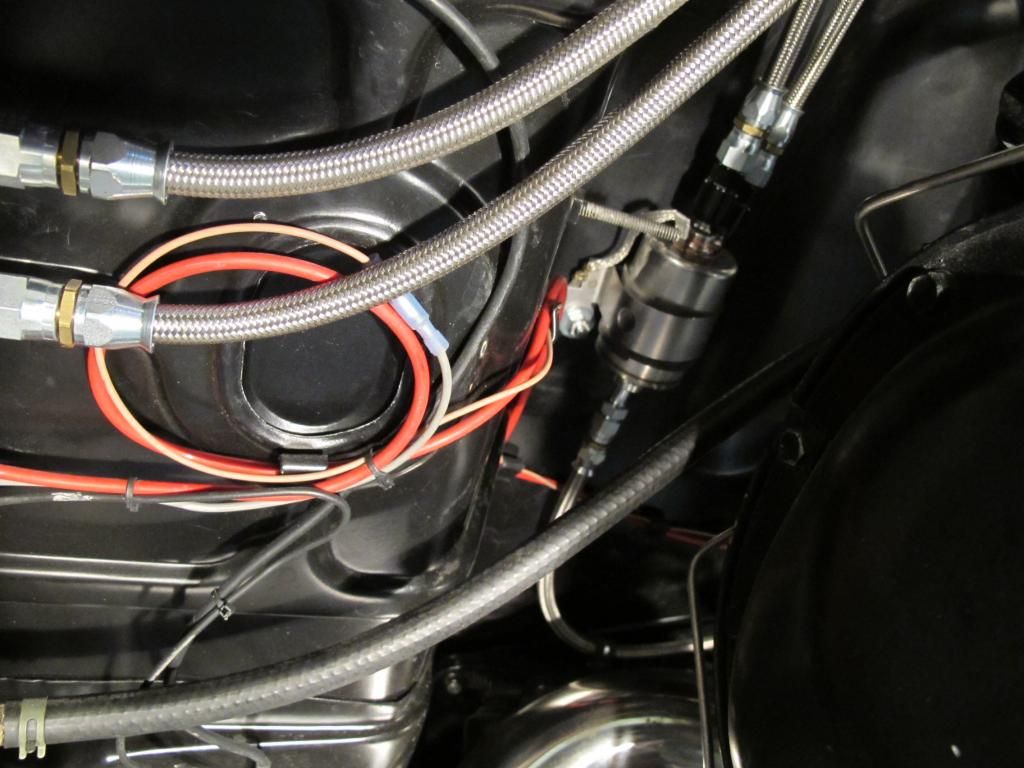

Holley engine adapters 12611, Car Shop BOP to Chevy frame mounts and energy suspension 3.1114G mounts (short and wide required.

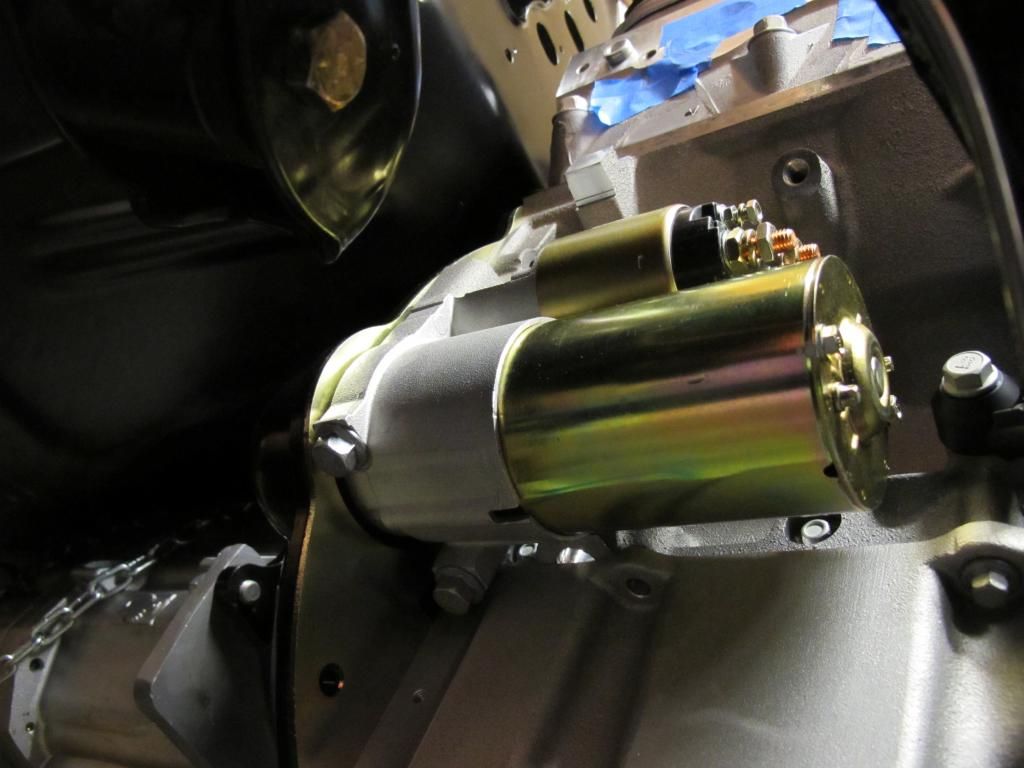

Bosch SR8581N starter from Rock Auto. $107. No core and brand new.

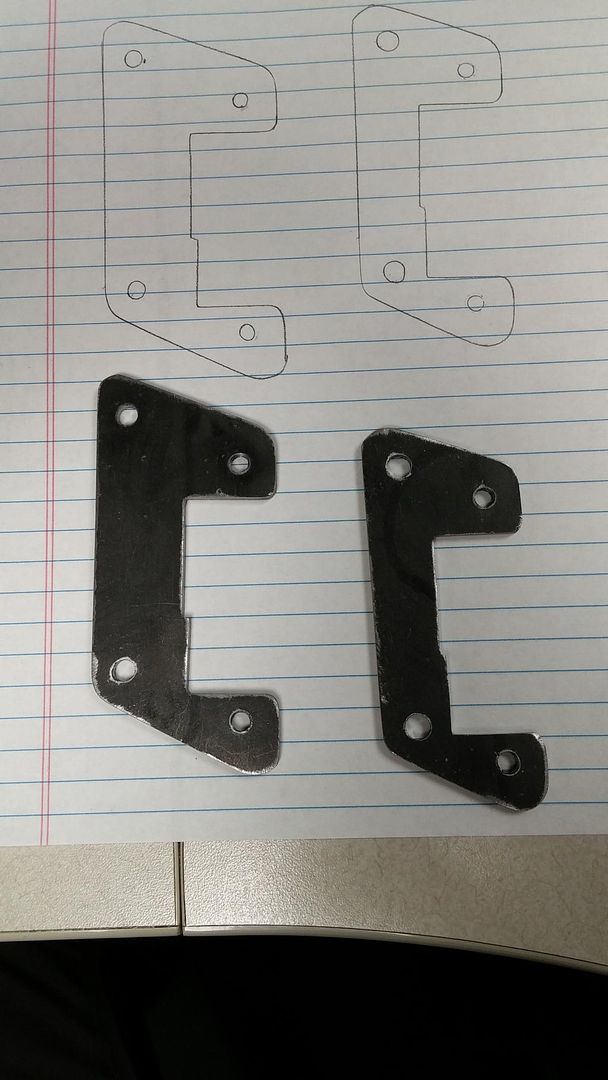

Trail and error with Doug's D3336-R headers. The headers fit fine at the frame and clear the steering column OK. I tried the Dougs SK100 mounts which are IDENTICAL to the Hooker mounts except that the engine can move forward by 3/4" from stock location. If I put the engine 3/4" forward, the headers barely clear the lower a-arm suspension pockets.

While the D3336-R headers fit OK at the engine and between the frame rails, they are really tight to the floor. I have about 1/2" at best between the header flanges and the floor. I am exploring other headers with Ultimate Headers to see what they can do. My other option is to cut off the flanges, weld in some 3" elbows to move it away from the floor and clear the crossmember. I ordered a new Summit Racing cross member and should have a good idea where things are going after that arrives.

Linear Mode

Linear Mode