| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

||||

|

||||

|

Does anyone know how these cars were painted? Did they come painted from the Fisher body plant, or were they painted at the assembly plant? Were the cars painted first and then disassembled prior to going down the line? When the doors, hoods, trunk lids installed, were there racks of different colored items waiting for the appropriate colored car coming down the line? I'm guessing that the door panels were already installed on the doors prior to installment. Any idea on how special order cars were handled? Are there any book on the assembly process?

__________________

1966 GTO Vert automatic. 1969 CR Judge Ram Air III 4sp Pattern Car. 1969 GTO standard 350HP TH-400. 2006 GTO Phantom Black 6spd. 1972 Formula 455HO Ram Air. 1976 LE Trans Am 50th Anniversary Edition with T top. 1976 Formula 350. 1977 Grand Prix Model J 350. 1978 Trans am 400 Pontiac. 1979 Trans am 403 Olds. 1968 Olds 442. 1971 TR6. |

|

#2

|

|||

|

|||

|

Firewall back was painted as 1 assembled unit , at Fisher plant.

Bare hull with doors and trunk lid bolted and aligned. Zero trim. Lacquer paint with electrostatic guns , to help get the nooks and crannies hinges etc ... Then oven baked at 360* (another reason they were just bare body hulls). The baking increased the durability by about 10 fold - versus standard air dry lacquer. And eliminated the need for wet sanding / buffing of the finish. i don't know what year range they went to robotics to do the body spraying , and don't know if our era of cars were hand sprayed or robot. Fisher also did the black out work, and any dash/trim color work of the firewall back body assembly. Including the trunk splatter. The GM plant did all other paint work for front end sheetmetal and various etc's ... Some miscellaneous small pieces and non-metal pieces were supplied in color by the manufacturer/supplier of those pieces. But it must have been a highly regulated and strictly controlled process to keep mismatches at such a minimum between doors and fenders. Pretty wild. In the 80's and 90's - we rarely had new Cads or Olds that were factory mismatch. But we did have maybe 4-10 a year that were significant enough to need correction. i was amazed when i learned the front half and rear half were sprayed at different times at different places from different batches of paint. That is as far as i can take it. i also would like to know the full scope and range in the 60's and 70's. And how special order paint was handled start to finish. |

|

#3

|

||||

|

||||

|

I've been building cars in GM assembly plants for 34 years, as a production supervisor, in Product Engineering and (for the last 14 years) in new product launch. This link is probably the best I've ever seen in describing the process:

http://www.camaros.org/assemblyprocess.shtml#chev (I see no reason to write my own since this one is so well done). Keep in mind there is some variation in process between plants (sometimes variation between different lines within the same plant). Also- take a look at this, which includes truck plant photos and some commentary: http://www.73-87.com/7387info/Assembly%20Line.htm I'd be happy to answer any specific questions you might have after looking at those two links. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-10-2013 at 05:58 PM. |

|

#4

|

||||

|

||||

|

Quote:

a) Painted at the Fisher body plant. Bare hulls, doors installed. Cars went from paint to General Assembly: Trim, where interior and exterior trim were added, and then on to Final line, where the body was mated to the chassis (or subframes) and front end sheet metal added and fitted. It is, admittedly, a lot of fun to look at how cars are assembled in an assembly plant because the build sequence is really not how you would do it if you were (re)building the car in your garage. b) Bodies were painted with doors, trunk lids installed; front end sheet metal was typically painted in a separate area (opposite ends of the plant, or even a different part of town), but as we got smarter in later years we began placing the sheetmetal on a fixture in front of the body assembly so that it was sprayed at the same time. Probably in the early 80's or so. c) Everything was in sequence for that specific build; said differently, there weren't generic racks of color parts just waiting. If you've ever seen a "build sheet" - that's what the build sheet does. It defines the option content for that car, and then the next build sheet describes that car, etc, all the way down the line. d) Special order cars were handled just like any other car; the specific information, option content, part numbers, etc, were broadcast in sequence and everything flowed together after that. e) Back then, doors were installed on the car and then trimmed out on the car after paint. Best practice these days is to install the doors for paint, then remove them early in the trim operation. They are placed on a separate conveyor where they are trimmed out (allowing the operator easy access and the ability to stand upright) and then re-installed on the body on the final line, after seat install. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-10-2013 at 06:08 PM. |

|

#5

|

||||

|

||||

|

We still were spraying by hand when I started in 1979. In fact, a guy could be sweeping the floors one day and painting cars the next.

We went to robotics in the mid to late 80's at truck, both reciprocating arm sprayers and then, slightly later, a "turbine bell". The "Mini bell", as it was called, was a Behr product. It was a small head, like a shower head, that spun at a high rate of speed (ie, 20,000 rpm) and slung the paint towards the car. The car was electrically charged so that the paint particles were "drawn" to it. In fact, you could stand next to the car and see the paint going around corners to attach to the back side. The only problem was....the electrical charge would cause all the metallic particles in the paint to line up in an orderly fashion. This, of course, meant they didn't match the paint chip - or the front clip. We ended up spraying a top coat on those metallic colors manually in the paint repair both so that everything would match like it was supposed to. Non metallic color cars could just pass right through. By the way, BVZ makes a good point that many smaller components come in painted/detailed from the supplier (headlight bezels, center consoles, emblems, etc). K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-10-2013 at 06:14 PM. |

|

#6

|

|||

|

|||

|

Thanks for the Camaro link Keith.

Like you mentioned - certain details probably were different from plant to plant regarding application and certain specifics - but general practices the same overall. i wasn't aware Fisher did as much on their side as they did. Had been asked before and wondered about when/where cowl tag and VIN tag were installed. Lots of good info and answers in that write up. Looks like the paint bake temperature wasn't quite as hot as i had been told. But 275* is still plenty warm. Most of the new car paint problems we had to address on brand new cars fresh off the hauler were due to "spot repairs" done at the plant. They were indeed "spots". But they were not something we saw every week or even every month, on a regular basis. Mismatches were very seldom and became less and less seldom in the tale of times. i'm not including the probs we had with 1st gen bc/cc acid rain and rail dust damage of the clearcoat in the later 80's. Or the delamination problems of the mid 90's. Those weren't production/application faults, just faulty products. Last edited by Baron Von Zeppelin; 02-11-2013 at 01:30 AM. |

|

#7

|

|||

|

|||

|

Quote:

As soon as it was painted and baked - and cooled - it was beginning the assembly process. Looks like while the firewall back was being painted at Fisher - the Front pieces were being sprayed accordingly at GM at about the same time - or exact same time. Was a well oiled scheduled process in advance. Reads to be that they only painted what was needed - as it was needed - on demand. Not hundreds or thousands of front end pieces in every available color stacked back in waiting. Just the supply for that days demand. Also it reads that "special order" colors were sprayed by hand - unless it was something like a Fleet Order of 100 or more. |

|

#8

|

|||

|

|||

|

Question for Keith

Some of the things spoken about are mentioned more than once, and some things seem like they might not be in exact chronological order. But most of that is trivial overall. The thing that stood out the most to me was where it mentioned things like emblem holes, spoiler holes, antenna holes .... it seemed to read like those holes were performed AFTER paint ?? is that correct ? or is that just a trivial element of how it was written ? |

|

#9

|

||||

|

||||

|

BVZ - did I not send you a .pdf file of the "Made in Pontiac" series? I sent it via email to the Boss and a bunch of other folks...

At any rate, here is a link to the "Wild about Cars" site, where it can be accessed: http://wildaboutcarsonline.com/cgi-b...=9990401240631 Written by our own Eric White (gtoric), it was originally published in the Legend and more recently in Smoke Signals as an 8 part feature (shown here in 5). It was/is an interview with a PMD employee and is the definitive work on the 1963 - 1965 ish Pontiac Michigan assembly process. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#10

|

||||

|

||||

|

I'd like to comment briefly on the plant-to-plant differences, highlighting the "within plant" differences I mentioned.

When I started at Chevrolet Flint Assembly there were two assembly lines under the same roof: Line 1 was light duty pickup trucks and Line 2 was the only assembly line in the world building the C/K/R/V Blazer and Suburban. Line 2 built up the front ends via "buck build", as shown in the Camaro link. Line 1, during the same era, built the pickup front ends "piecemeal", that is, one piece at a time. Radiator supports were set on the chassis just after motor set and then the LH and RH front fenders were installed independently after body drop. Hoods were intstalled a few stations down from that. I cannot explain this difference in process but I will say of the 10 C/K plants I supported only Oshawa and Flint Line 2 used the buck build process; the remaining 8 plants built the front ends piecemeal. This is also true for the 1965/66 era Pontiac Michigan assembly plant (ie, piecemeal build). K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-11-2013 at 10:36 AM. |

|

#11

|

|||||

|

|||||

|

Quote:

Quote:

(I can also state that the RPO K05 block heaters worked well for heating water for coffee.) (I can also state that the RPO K05 block heaters worked well for heating water for coffee.)Quote:

My '65 GTO (original paint) has a terrible paint job, including a couple spots where the paint did not stick. My Chevelle was damaged in the assembly plant and repaired, which we did not discover until many years later when it got it's first re-fresh. Quote:

Quote:

K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-11-2013 at 10:54 AM. |

|

#12

|

||||

|

||||

|

Quote:

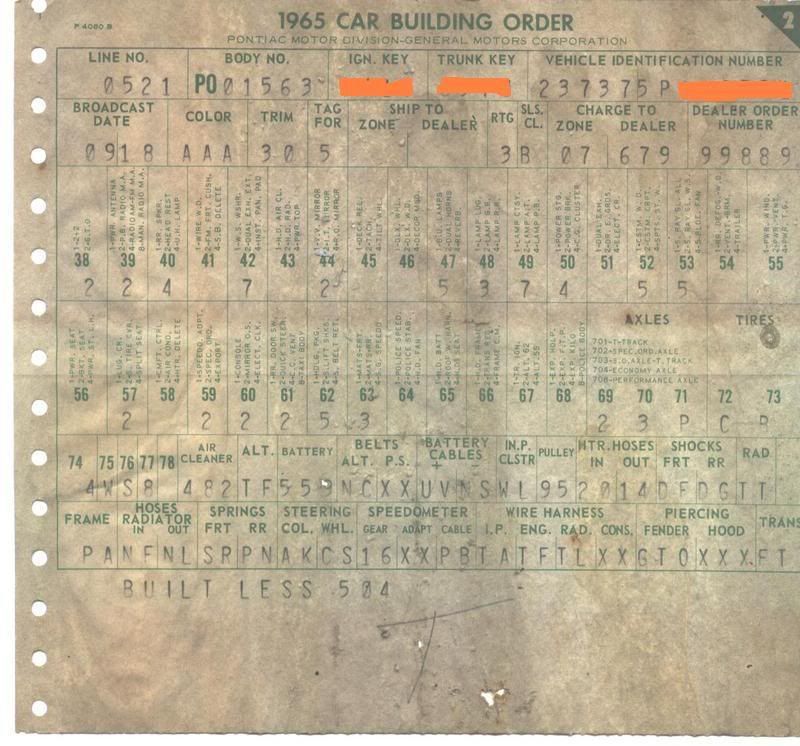

Drilling holes after paint is generally avoided due to corrosion concerns (in fact, in later years we went away from holes altogether in favor of adhesive moldings/emblems). Holes are normally put in the base individual sheetmetal part when possible (without causing undue part proliferation) or drilled after the body is complete but before paint. The build sheets (build manifest) for mid 60's Pontiacs have a spot that indicates what holes are required to be "pierced", particularly with respect to front end sheetmetal. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-11-2013 at 10:52 AM. |

|

#13

|

||||

|

||||

|

So....Charles....how you doin' on your reading assignments?

http://www.camaros.org/assemblyprocess.shtml#chev http://www.73-87.com/7387info/Assembly%20Line.htm http://wildaboutcarsonline.com/cgi-b...=9990401240631 There will be a quiz afterwards.... K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#14

|

|||

|

|||

|

i think the Camaro author was mostly going forwards, and looking back once in a while filling in missed details etc...

Chevy side - Paint Operations he covers the stamping and joining/welding of inner and outer fender priming and painting the parts Then he moves onto Chevy side - Front metal subassembly "" Alll the color-painted exterior front sheet metal panels, plus the black-primed radiator support, inner fenders, and center grille support and the low-bake painted grille were conveyed to the sheet metal assembly area; all were in "Broadcast" sequence, matching the sequence of bodies on the main assembly line. Option holes for engine emblems, antennas, Vigilite housings, nameplates and moldings were pierced in large hydraulic fender piercing fixtures before the fenders were placed in the assembly fixtures."" The way that is worded - and its chronological order - makes it read like they didn't do those holes until after paint - just before the painted pieces were placed onto the subassembly jig fixture. i didn't think that sounded correct - but wanted to verify. He also made it sound like rear mounted antenna holes weren't punched until after paint - done way over on the Chevy side. Same deal as the fender holes. The mentions were him reflecting backwards. Just wasn't sure if Camaros were done bassackwards - or if the wording and placement of some wording were the real issue. |

|

#15

|

|||

|

|||

|

Wouldn't it also be probable - if a body shell were painted and baked in the morning hours - that Fisher side would begin doing their assembly work that same day ?

Another question : On a 69 Judge - would Fisher have installed the door and quarter sword stripes - or would they have all been installed later on PMD side after the car was 1 piece. Friend of mine just did a Hugger Orange 69 SS Camaro. The car came with black side hockey stick type spear stripes on fender and doors. He said from the factory - the door portion was a decal - and the fender portion was painted. lol That led me to think Fisher did the door decal - and Chevy laid off the masking for fender stripe adjoining from the door decal . He painted it all back on. |

|

#16

|

|||

|

|||

|

This type stripe is the one i'm talking about.

|

|

#17

|

||||

|

||||

|

Quote:

K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#18

|

||||

|

||||

|

Quote:

Quote:

We installed adhesive stripes on the fender in the front end sheet metal build area, and on the doors/body in paint, hoping it would all line up on the final line. I wouldn't do a paint stripe and a decal on the same vehicle, but you never know.... K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#19

|

||||

|

||||

|

Quote:

I am reading everything you are sending. Keep sending what you can if you have the time. Never thought that I would have got a response from one who has first hand knowledge on the subject. I have always been interested in how the assembly line worked and would have loved to take a tour of the Atlanta GM plant where my 69 GTO was assembled. I lived in Atlanta from 73-86 and drove by that plant thousands of times. Would loved to have worked there. Thanks again!! Chuck

__________________

1966 GTO Vert automatic. 1969 CR Judge Ram Air III 4sp Pattern Car. 1969 GTO standard 350HP TH-400. 2006 GTO Phantom Black 6spd. 1972 Formula 455HO Ram Air. 1976 LE Trans Am 50th Anniversary Edition with T top. 1976 Formula 350. 1977 Grand Prix Model J 350. 1978 Trans am 400 Pontiac. 1979 Trans am 403 Olds. 1968 Olds 442. 1971 TR6. |

|

#20

|

||||

|

||||

|

Keith, here's one thing I can add and you might double check concerning your time line. I bought a new Chevy Caprice in 1985. It was a blue metallic that looked great in the showroom. But once you got it out in the sunshine the front sheetmetal was obviously a different shade. Actually it looked like it had 'less' metallic in the paint, making it appear a lighter shade out in the sun. At first we thought it might have been damaged and the entire front end resprayed. But then we compared another Caprice the same color on the lot. Same deal. So it appeared that in 1985 that the Caprice body panels were painted at different locations/or times.

__________________

LEAD, FOLLOW, OR GET THE HE!! OUT OF THE WAY!!! HONEST JERRY'S SPEED AND EQUIPMENT

|

| Reply |

|

|