Material needs to be removed evenly from the short turn side and the opposite wall until you've reached the diameter where you can get the template past the throat. As Paul says, you need to flatten it at the top to match the width of the port then carefully round it as it approaches the valve.

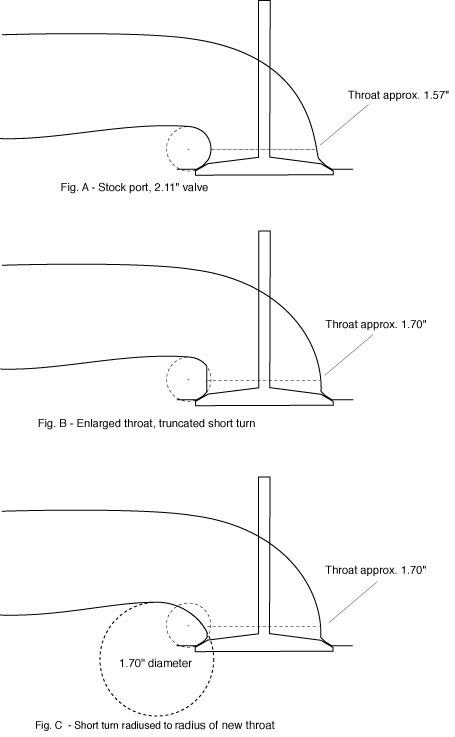

Here's a simple diagram that shows the goal for the port cross-section.

short_turn_diagram

short_turn_diagram by

Will Baker, on Flickr

As you can see, most of the work is in the short turn area. DO NOT lower the port floor above the short turn but you do need to lay it back a little to get the proper radius.

Here is an album of pictures of some head porting I've done. I'm just an amateur, but I've ported a couple sets of heads and had my results verified on a flow bench. Doing what you see in the pictures has resulted in ~245 cfm @ .550" with better flow than stock throughout the lift range.

https://flic.kr/s/aHskQGc7b9

Remember, you can always take off a little more metal, but putting it back on is really hard to do.