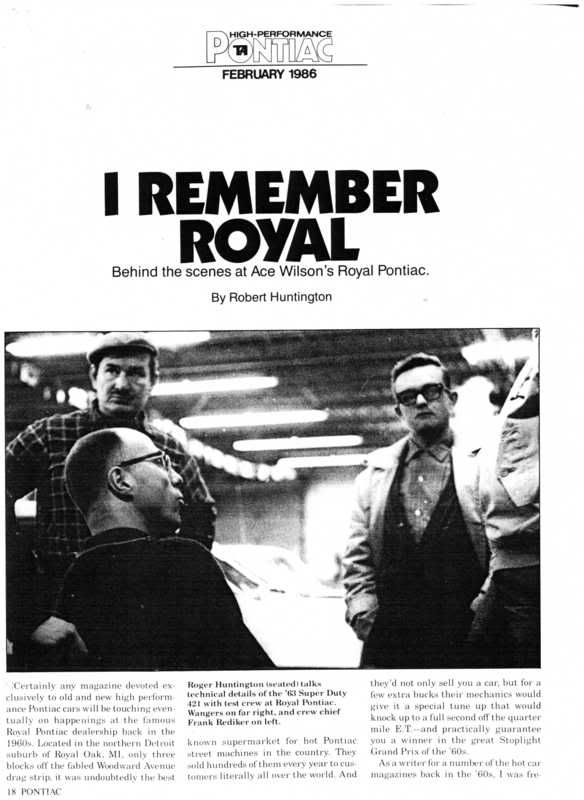

Dad had the opportunity, through his connections at Royal, to work a little bit with Roger Huntington. For those not familiar with Roger he was a free-lance author and tinker-er, and fancied himself to be somewhat "forward thinking" in the areas of performance and automotive engineering. He probably was, actually, but was crippled by polio and therefore wheelchair bound; as a result he had to live out these theories through others and the subsequent articles.

Recall that the main issue facing these high horsepower cars back then was the lack of traction. Conventional wisdom called for production rear suspensions, as released by the manufacturer, and the addition of "Atlas Bucrons", or some other "soft" compound tire. There were no wrinklewalls, no "fat" tires, no water burnouts, and traction compounds were for the fledgling professional race categories (if at all).

There had been some thought that "longer" rear control arms were better, perhaps resulting from successes with the Swiss Cheese cars and other big Pontiacs. In fact, some work had already been done installing these longer Catalina lower control arms on the smaller intermediate sized GTO's.

Roger proposed that this thinking could be taken to the extreme: if a lower control arm, or traction bar, could be fabricated to attach all the way up at the car's "center of gravity", then that would be ideal, right? So between he and Dad they devised a scheme to fabricate such a device and install it on our GTO. The sketches you see here are the result of that brainstorming session.

The first order of business would be to locate the CG of the car, in the fore/aft direction. Dad had told me previously about jacking the car up, using a small scissors style jack on each side, and moving them forward and rearward along the car until it "balanced" with the front and rear tires off the ground. This would establish the location for the forward attachment point, at each frame rail. Square tubing was used to fabricate the bars themselves and they were clamped to the rear axle tube to secure the rear of the bar.

In short order the new setup was ready for testing. Arrangements were made to rent one of the local tracks and Dad and Roger met there with high hopes and great expectations. After warming the car, Dad proceeding to the starting line for the first test pass. Equipped with a skinny set of M&H "Racemasters" - a couple short, "dry hops" indicated everything was in order - Dad staged the car and the tree came down. Dad launched the car and

BOOM!! it immediately spun end for end, moving only a few feet forward and pointing exactly back the way he came. Shaken, Dad "putt-putted" back toward the bleach box area and shut the car off to regain his composure.

After a short break a second run was attempted. Dad tried "driving" the car out (a much less violent launch), but the car never gained traction down the quarter mile, slipping and sliding until the run was finally aborted. The "traction bar" concept seemed to be a dismal and complete failure, after just these two attempted passes.

Today, in hindsight, we can see why these would not work. Per the "doorslammer" chassis guru's, like Chris Alston or Dave Morgan, the instant center of the 4 link rear suspension is driven rearward and down from the production location, providing more "percentage of rise" when compared to the car's center of gravity. Today we would never consider moving the instant center to go directly "through" the heart of the CG; what they had tried out was completely "directionally incorrect".

As has been said before, you can learn as much from your mistakes as from your successes. The rear suspension was returned to it's "production" configuration (ie, control arms attached at their original locations, reworked bushings*, air bag located in right rear spring), and it is in this condition that the car ran it's best ET and is how it sits today. It is basically the same setup that I have on my bracket/index car today.

Dad had mentioned that some of the bracketry and holes can still be seen under the car; I haven't checked specifically but the next time it's up in the air I will take a look.

K

*an old hot rodder trick is to drive 10 penny nails longitudinally into the bushings. The diameter of the nails take up space inside the bushing, compressing the rubber further and giving the end result of making the rubber appear "harder". Today we would probably simply purchase polyurethane bushings and install those but back then they were not yet available.