11-05-2022, 10:06 PM

|

|

Ultimate Warrior

|

|

Join Date: Nov 2002

Location: ABQ, USA

Posts: 5,024

|

|

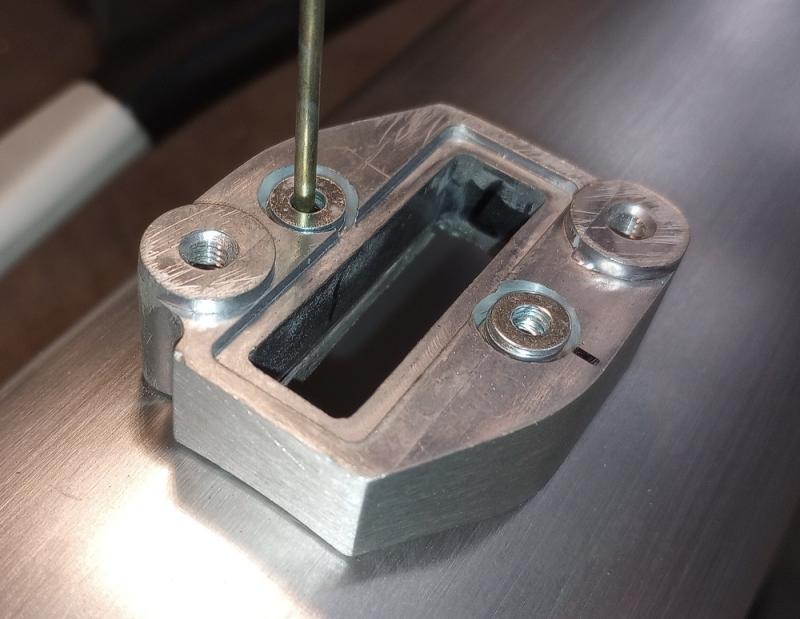

One of the issues that bothered me was how to mount the MAF mount. It has two threaded holes but nothing else. Bolting it in was a no-go - if the screws come loose that is bad news! Eventually I figured out rivets are the way to go here.

Two ways I can see to do this. One is simply buy long rivets, the other is to drill and counterbore. That is the path I took.

First you need to cut open a rectangular hole for the sensor. I use an angle grinder with cut off wheel. Not the best as it is not a clean hole and the cutting disc can load up with aluminum.

File work will clean this up.

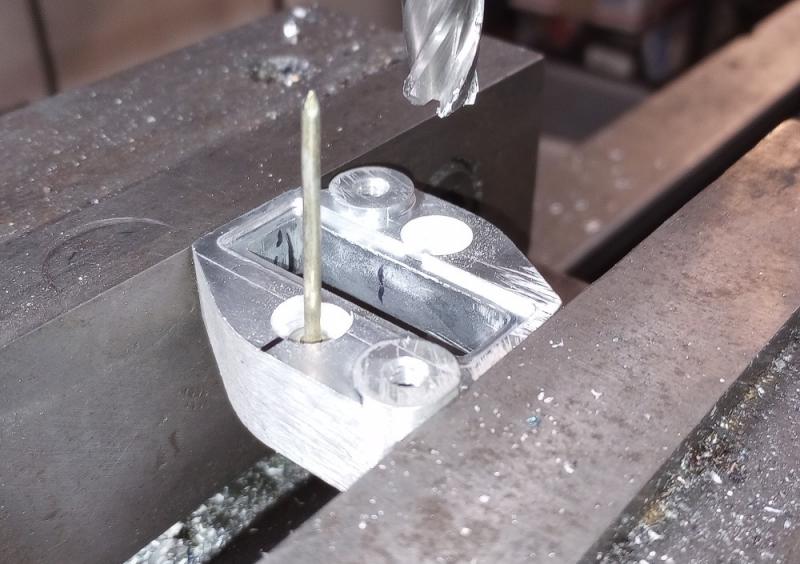

Time to drill and counterbore. Rivets required about 3/16" of material to fall into grip range.

Rivet tool would not reach into hole so washers were stacked till flush plus a bit more.

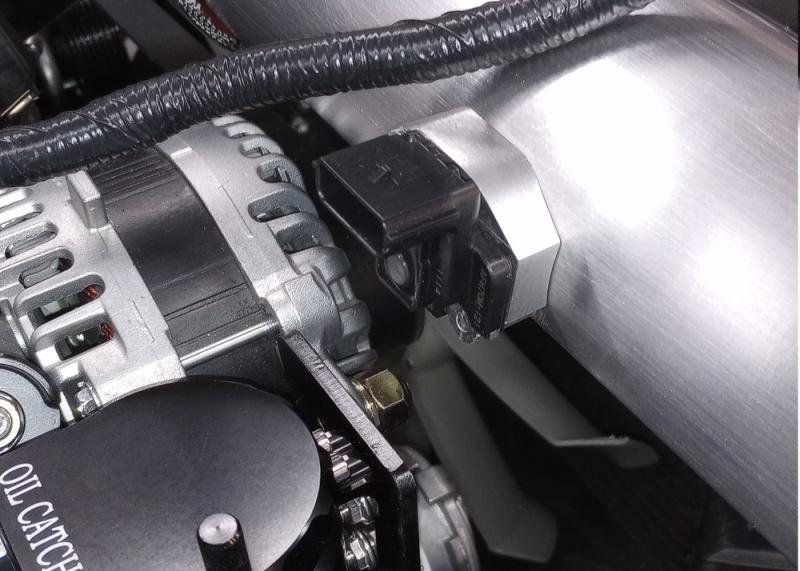

Make sure mount is clocked the correct way - the blade style only flow one way.

Test fitting in engine compartment. I will use sealant around the perimeter of the mount - no leaks here! Pipe will be scotchbrited then cleared after sealant dries.

I hope there are better mounts that already have mounting hole and rivets ready to go...

Last edited by Scarebird; 11-05-2022 at 10:13 PM.

|