| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#21

|

||||

|

||||

|

Quote:

|

|

#22

|

||||

|

||||

|

Quick newbie question ...

There is a functioning bypass valve IN the basic Pontiac aluminum right angle filter adapter that bolts to the block? I've never looked at one that close .... so it's probably not a good idea to glass bead one of those adapters? Can it be disassembled and cleaned? |

|

#23

|

||||

|

||||

|

Yes,it's cake to take it apart and wash it out!

For years I have run with the bypass blocked and then ran a remote duel filter mount with 2 quart filters hanging off it. The flow rate even if you ran gear lube in the motor at -20 degree temps is huge!

__________________

Wernher Von Braun warned before his retirement from NASA back in 1972, that the next world war would be against the ETs! And he was not talking about 1/8 or 1/4 mile ETs! 1) 1940s 100% silver 4 cup tea server set. Two dry rotted 14 x 10 Micky Thompson slicks. 1) un-mailed in gift coupon from a 1972 box of corn flakes. Two pairs of brown leather flip flops, never seen more then 2 mph. Education is what your left with once you forget things! |

|

#24

|

||||

|

||||

|

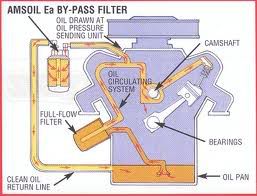

An article about the inefficiency of full flow systems and advantages of a by pass filter system in actually keeping the engine oil clean and extending the oil life up to 8 times that of a conventional full flow system, while cutting down engine wear by removing finer contaminants. They also talk about the restriction to vital engine parts with a full flow filter system and need of a bypass valve to keep internal parts lubricated.

The article also speaks about GM's own study done along with the SAE, that proves that there are much better filtering systems available than the factory engineered full flow system in reducing wear and extending oil life. Taken also from Machinery Lubrication: Quote:

__________________

Brad Yost 1973 T/A (SOLD) 2005 GTO 1984 Grand Prix 100% Pontiacs in my driveway!!! What's in your driveway? If you don't take some of the RACETRACK home with you, Ya got cheated

Last edited by Sirrotica; 06-01-2016 at 08:09 AM. |

|

#25

|

||||

|

||||

|

NO FILTER can remove fuel once it is introduced into the oil. If you have fuel in the oil then it has to be changed, no ifs and or buts. If you have more than a minute amount of fuel in the oil you have a mechanical problem that needs addressed and repaired.

|

|

#26

|

|||

|

|||

|

Something to keep in mind is that the majority of Dirt is introduced into engines by the Air Getting drawn in past the air cleaner or no air cleaner used.

|

|

#27

|

|||

|

|||

|

It also comes down to what an individual can afford or wants to spend.

Use what Pontiac Engineering gave You. Full Dry Sumped is best. $5,000 -$8,000 spent is typical . 11-15 quart total oil system capacity. |

|

#28

|

|||

|

|||

|

I just dont understand how so many pontiac engines in the 60-70s and 80s went 100K miles with the original system and the crappy old oils we ran back then?Tom

|

|

#29

|

||||

|

||||

|

Yeah I just don't think an old car running a carburetor should be going past 3000 miles regardless of what kind of filter you run.

|

|

#30

|

||||

|

||||

|

Quote:

Your free to think whatever you'd like, the truth is if the carb is setup properly there will be little to no fuel getting into the crankcase. As I said fuel in the crankcase oil is because of a mechanical problem, not what type of induction system you have on an engine. Washing the oil film off of the cylinder walls will lose the ring seal and lead to fuel in the oil. Having a flooding carb, a defective mechanical fuel pump (ruptured diaphragm) are mechanical problems, not induction problems. The by pass filtration system is quite old and was used since the 50s on carbureted cars long before fuel injection was common on production cars. It was used to extend oil changes and offer superior filtration extending engine life, over 60 years ago. By pass filtration is far from new and was used on Detroit iron when oil filter systems were optional. If you specified an oil filter on your car it was a by pass system, not full flow. Filtering oil inline on the pressure side of an oiling system is far from the ideal way of keeping oil analytically clean. If you bothered to read the article from Machinery Lubrication it lists all the reasons why a full flow system is marginally better than no filter at all, and the benefits of a by pass filtration system are head and shoulders over any system Detroit hung on the engines in the fifties and since. Really if the car companies used a more expensive by pass filtration system, the engines would have probably close to doubled before becoming worn out. Can't sell a man a new car when he already has a great running engine in his old car, if the rest of the car is still serviceable. Can anyone explain to me why even with written proof there is so much resistance to use something many times better than Detroit engineers designed? If it were new cylinder aluminum heads that we were discussing over cast iron original parts, no one would be arguing that the iron heads are superior. Damn, GM even did a study and it has the same results, what more is needed to prove that the full flow system is hardly filtering any of the harmful particulate from the oil? They say in their own study that oil properly filtered is safe to run up to 8 times longer than a full flow system. Tom S, with better oil filtration the old Pontiacs would probably have reguarly run over 200,000 miles. I had a 76 Safari 455 that made over 160,000 on the original engine before the body got so bad it was junked. Not sure how many more miles the engine had in it, but it still ran good and was quiet when it was scrapped. |

|

#31

|

||||

|

||||

|

A by pass filtering system isn't even 10% of your lowest figure. The truth is it will actually pay for itself in a short time. In 2011 I installed one on my 93 K3500 turbo diesel when I changed oil. The next time I changed oil was in 2015, 4 years and a hair over 25,000 miles. At that time I did the calculations and the system had completely paid for itself in oil and filter changes. I recovered the complete cost in 4 years. Best part is I own it, and if I decide to buy something else I can transfer it to the new vehicle is a couple hours and sell the truck with the original full flow system. My truck now has 253,000 miles on it and runs as well as any other 6.5 diesel I've seen. Oil pressure hot going down the road is about 45 lbs.

|

|

#32

|

|||

|

|||

|

Quote:

__________________

1968 Firebird 400 RAII M21, 3.31 12 bolt, Mayfair Maize. 1977 Trans Am W72 400, TH350, 3.23 T Top Everyone you will ever meet knows something you don't. Bill Nye. |

|

#33

|

|||

|

|||

|

Quote:

We have never chatted prior. Do You have something better than what GM used & Guaranteed to flow 18- 30 gallons per minute at 80 psi- 150psi Hot oil pressures ? Really I not concerned with 1 micron filtration. Depends what article you read. Some say 40 microns is Ok. Others 20 microns. Real World racing & street use I like. Anytime you run external oil lines its a future chance area of hoses & fittings blowing out. Dont ever say it does not happen because it does. Why only Premium High end Forged AN Race fittings & Teflon lined Stainless steel braided hoses should be used. |

|

#34

|

||||

|

||||

|

Quote:

|

|

#35

|

||||

|

||||

|

Quote:

The filter system that Detroit designed is flawed, GM says in their study that a by pass filter system is better than their full flow system, the people that designed the system admit there are better alternatives. How does knowing who I am change that? I don't believe you know how a by pass system works, so I will post a simple diagram so you can see the filtering is completely independent of the oiling system fulfilling the needs of the internally oiled engine parts.  It takes about 5% of the oil from the oil pressure port and runs it through a 1 micron filter at the rate of about 1 quart per minute and simply returns it to the oil pan extremely clean. It does not restrict the vital oil supply to the internal engine parts. At this point the full flow filter becomes redundant and can be eliminated or kept in place. I made reference to running an Oberg filter so there is virtually no restriction between the pump and the internally lubed engine parts, or the stock setup could still be retained if an individual chooses to. The by pass filter system does just what it says, bypasses the full flow filter. It does a job that no full flow filter or series of filters are able to do. The line is only 1/4" inch ID capable of 200+ # working pressure at 250 degrees. There is no need for big diameter hoses and high pressure fittings as this system isn't supplying the internally lubed engine parts, it's doing one job, filtering oil to a new if not better than new condition and returning it to the pan cleaned. One other thing is this is the street section so the OP isn't running a full out race engine, it is conceivably a street engine he's asking about. Would I run a by pass filter on a race only engine? The answer is yes I would, especially my favorite form of motorsports, dirt track racing. Years ago when VW buggies were running the off road races like Baja, they used Frantz filters because the VW only had a screen in the pan to act as a filter, did little to keep the oil clean in the harsh dirty environment and made the VW engines much more dependable during long races. So yes these types of filters have been run in race only applications with excellent results. If the oil is kept in a pristine condition and has no abrasives in it you simply change the filter element and leave the oil in the engine. One quart of makeup oil is added when the filter element is changed replenishing the additives. Clean oil doesn't exhaust oil additives nearly as quickly as oil charged with 0-40 micron particulate left in by full flow oil filters. There is no down side to running a by pass filtration system, the same can not be said of a full flow system, even GM admits it. Any oil analysis company will tell you the more fine particulate that is removed the less wear in any lubricated machine, be it a hydraulic system or an engine. This from BLACKSTONE LABS in Fort Wayne IN, probably one of the largest and best known oil analysis labs has to say about by pass filtration: Quote:

|

|

#36

|

||||

|

||||

|

Quote:

Even fuel that does get in the crankcase, if it's not excessive will boil off when the oil turns hot and either be lost through the breathers or PCV system. Fuel will vaporize long before the oil reaches operating temperature so it will be purged anyway, unless it's excessive due to a stuck float or faulty fuel pump, faulty mechanic, etc. You keep the full flow filter and keep changing your oil when it's dirty so the guys with waste oil heaters have plenty of fuel next winter.........

|

|

#37

|

|||

|

|||

|

I was told by a Engineer that after GM went to FI, all the cylinder wear issues they had stopped. Nothing like a richer than necessary mixture washing oil off the walls.

|

|

#38

|

|||

|

|||

|

Quote:

And also a Diesel Mechanic. 46 now. I like dirt track racing too. I was involved from 2006-2011. Head mechanic for 2 cars- drivers local. 1/4 mile high banked clay dirt oval. Top dogs run 700 -900 HP turning 9,000 RPMs. The bypass system your talking about was used on Allis Chamlers tractors WD & WD45 series. Not a bad thing. Just unusual. It could work. Just have never seen it used on the Auto side at all. I have a 1960-61 Pontiac Tempest 4 cylinder factory Oil filter adapter block off plate. Like the one Bruce Fupler shows on his website & covering this topic.' Exact as he used Super Stock Drag Racing in the past. No oil filter. T/4 Cast iron bypass plate bolted on. I am planning on trying it on one my Pontiac engines. Perform tests. With the Factory Right angle oil filter adapter and unmodified. Another with 3/8" Allen pipe thread plug in. Then the T/4 cast iron bypass plate. It was a hard bypass plate to locate but I have it. |

|

#39

|

||||

|

||||

|

I just don't see too many enthusiasts wearing out their engines from using the factory filtration system.

|

|

#40

|

|||

|

|||

|

Yep. Std bore blocks are a dime a dozen. ; )

__________________

1968 Firebird 400 RAII M21, 3.31 12 bolt, Mayfair Maize. 1977 Trans Am W72 400, TH350, 3.23 T Top Everyone you will ever meet knows something you don't. Bill Nye. |

| Reply |

|

|