| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#21

|

||||

|

||||

|

Quote:

"like dude sez, some blocks do, some dont..there has to be a common denominator" The ones with the good tune-up did not fail the block, lol. Explain to me why a 67 factory block with splayed caps can make over 1600+ hp for THREE YEARS and be as good as new three years later. "Everyone knows" the factory blocks will fail at 750 hp in most cases. There were so many "tricks" in that block/engine: Proper Tune-up, Good Machining, Right Selection of Parts, Correct Fuel for the Power, Ford Guy working on the engine, LOL! Kaase makes a lot of power too, he knows how to build GOOD engines, he was a "Ford Guy". Same deal with a guy named Tony with a Cougar that runs 6.30s at 220 mph. Tom Vaught

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#22

|

||||

|

||||

|

"This is just my opinion of course, but I have studied the Pontiac block(and other successful makes) from all angles,and as a result have made a simple crossbolted type of mains girdle ,for my application,that ties the oilpan rails together through the caps."

Can you post pics of your main girdle please?

__________________

68 Firebird Are you running with the wind or breaking it? |

|

#23

|

||||

|

||||

|

Ron, it's all stripped down at the moment,I've got the block in the hot tank to clean out the water jackets ready for the block fill. I'll take some pics when it's back together and post them.

|

|

#24

|

||||

|

||||

|

Quote:

block 1) broke the main web around the main cap bolt which let the cap come open and it fractured the crank. block 2) had a nitrous switch malfunction; oscillating the nitrous on & off a bunch of times and it split the block between two cylinders block 3) had a major meltdown of a piston that burned/scored the cylinder wall deeper than we felt was repairable. Indian Adventures introduced their block right about that time and the switch was on. We're still running the same (2) IA-1 blocks. Arnie would regularly split stock blocks after just a handful of passes on his blown, nitro combinations. He thinks they were probably in the 1500 hp range at the time. The factory "funny car" block was designed to address that problem. Eric |

|

#25

|

||||

|

||||

|

Ive been Chamfering the Sharp edges of the Oil holes where they merge that go from the cam jrn down to the mains to get rid of sharp edges as It just seams to be a spot thats begging for a crack to start, I believe dude is correct about the Very litte Main BulkHead Material and Another suspect is 4-bolt blocks and How deep the Outer holes have been drilled, Several Stress Risers in stock blocks to tend to IMHO if they are to live at Power, Another point is Sollid Mounts are Very Counter productive! Especially with High rpm and Hi HP, Think about your 80lb crank with Heavy steel rods and TRW's spinning at 7000rpm Imagine the forces that are trying to rip that bloc in half!! Thats Why any Weight you can get rid of there will help as will shorter stroke's JMO

__________________

D.S.R.E. Your NW Pontiac Street/Strip Engine Builder, Specializing in Cylinder Head,Intake Manifold,and Exhaust Manifold Porting services and Building the Most Efficient stock rebuilds to Hi HP Pump Gas and Race Combinations for Pontiac,Buicks,Olds,FE Fords,385 Series and HP Gen 3 and 4 LS engines! 2006 silvy Z71 4X4,383 LS 600+hp NA Shared Toy-66 Lemans 470cid by me 537hp 580tq-manifolds, 570hp 590tq-2"headers,custom cam,rpm intake, mild e-heads, Looks stock ;-} |

|

#26

|

|||

|

|||

|

Quote:

|

|

#27

|

||||

|

||||

|

Quote:

Also have to wonder how much of an effect crank flex may be adding as well. |

|

#28

|

||||

|

||||

|

Quote:

"Also have to wonder how much of an effect crank flex may be adding as well" Say you have an out of balance tire and wheel on your car and you try and run 100 mph for a while. How long do you think it would be before you fail the hub, the wheel studs, the bearings, or the spindle? Most would say probably not long. Imagine that you have the same deal with a flexing crankshaft where the forces are acting like the wheel out of balance. Most often the number 2 and 4 maincaps fail first in the factory blocks or the block splits up a not prepped factory oil hole due to a stress riser from the drillings. Good parts and attention to details will allow some parts to live a long "Hard Performance Life". Tom Vaught

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#29

|

||||

|

||||

|

Tom, Would a forged crank help with stress issues in a stock block?

|

|

#30

|

||||

|

||||

|

My opinion is,

1. The crank less-stiff-than-cast would promote PMD Block Splitting. 2. Steel Billet Main Caps, Thick Dowels, Main Studs do not prevent/lessen PMD Block Splitting. 3. Mech imbalance, Power Imbalance, Faulty Harmonic Damper promote PMD Block Splitting. Add Over-rev to induce the failure. 4. Sloppy Rear Trans Mount & cross member, Factory motor Mounts & Slicks promote PMD Block Splitting. 5. Rear Engine Plate is the most helpful aid I can think of to prevent PMD Block Splitting. 6. My Opinion: a 2.5" tall/taller Full Main Girdle that uses oil pan rail bolts looks nice. Probably helps restrain oil rails from TWIST that is part of the force-system that Split PMD Mains up to cam: see #3. ================================================== == Seems to me the Main Split failure is likely induced by Rod&Slug Accel at TDC, at hi-RPM, causing that Main-Cam zone to go into tension because Main Journal is pulled up-into that CYL, whereas the other Rod&Slugs are pulling-down on Mains and so-forth. Add a 1st gear TQ multiplier that is reacted at the engine mounts (not the Trans tail mount) and the recipe is set for "Main Web-in-tension go split". As can be deduced; the Most optimal Girdle would have no purchase on web-to-cam-to-web tension. Wishbone comes to my mind. If so, then the best remedy is a solid rear engine plate-to-frame. Rubber motor mounts, and to keep it real a front plate. Oh yea, I could be wrong. HIS |

|

#31

|

|||

|

|||

|

Quote:

Perhaps the vectors of forces arrows were hiding when you threw that thought out there. Then you wouldnt be wrong because you were deceived. |

|

#32

|

||||

|

||||

|

And imagine the imbalace and stress inducing loads that detonation may add?

|

|

#33

|

||||

|

||||

|

I visualize some way of having front and rear engine plate type mounting if possible that mount to the chassis in an insulated fashion. Seems a plate on each end of the engine would help tie it together as long as the chassis isn't twising the engine.

|

|

#34

|

|||

|

|||

|

But then greater chassis flex occurs vs solid bracing. Your idea great for a streeter but not optimum for a racer.

|

|

#35

|

|||

|

|||

|

That 55 Pontiac engine mount design team knew what they were doing.

|

|

#36

|

||||

|

||||

|

Quote:

|

|

#37

|

||||

|

||||

|

BruceWilkie, Yea you have a point. Gotta decouple from the pair of flexible frame rails.

Stiff: Then an ideal would be: Solid Passenger-side only Mid Plate, Front Plate, solid Trans Mount, solid Pass Motor Mount. Compliant: Rubber DS Mount, some sort of compliant DS Mid&Front plate; mounted to a Big-Car Motor mount for give. -------------------------------- IA II, IA I, MR-I, any sort of proven-safe mounting method with a PMD. ================================================ I just gotta say: Got the cam dialed-in, Rhoads in, torqued 1 head, HEI in, a huge slab of wild fish in the oven with sliced garlic all over, a bowl of garlic in olive oil, and me 2nd 16 Oz Yuengling Premium. Life is good. God is good. HIS Last edited by Half-Inch Stud; 03-01-2009 at 06:20 PM. |

|

#38

|

||||

|

||||

|

RonH, pics of the girdle in the race section. I was all ready to drop the block back in the hot tank when I remembered I'd painted the lifter valley area! Looks like the water jackets will have to make do with a pressure wash out.

|

|

#39

|

||||

|

||||

|

Couldn't a guy just use the soft factory style mounts at front left and front right (instead of a single centered front mount), then add the mid plate to handle the load?

Seems like the result would be the same. The soft mounts just suspend the weight but really transmit no stress to the block casting. Just shooting for a more factory look and less frame modification.

__________________

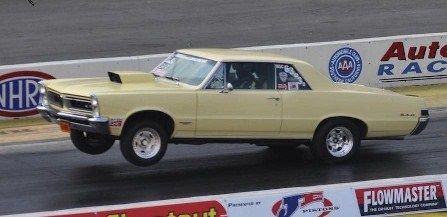

Brian Rock '65 GTO - Pump gas 496" IA2 w/ High Ports, 200-4R trans, 3.73 gears, 275 Hoosier radials, and 3925 lbs. 9.88 @ 134 N/A on Cali 91 octane. http://www.youtube.com/watch?v=NJEIY5OJ68g

|

|

#40

|

||||

|

||||

|

Has anyone seen a block split with no other apparent reason? I believe that the block splitting is a symptom of a worse problem. IE an end result, but not the cause. I know guys that have seen 3000HP on Pontiac blocks, they never split. The biggest problems on those old motors was crank snouts.

Yeah they did block reinforcement, but who wouldnt? It makes power. Yeah they did block reinforcement, but who wouldnt? It makes power.Lynn |

| Reply |

|

|