| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#41

|

||||

|

||||

|

Quote:

I know a guy who does clear(silver) & yellow(gold) cadmium. but usually I have to get everything for the entire project together & give it to him in a bucket. Have not talked to him in years so not sure if he's still doing it. He specializes in large commercial stuff & not restoration parts. He's just a car guy so it does it to help people out. I need to do something with my headlight buckets. they are galvanized. might do clear cad, bight that might be too bright looking?

__________________

68 GTO 4-spd Convertible 78 S/E Trans am L78, WS6 Auto 78 S/E Trans am W72, WS6 Auto 79 10th aniv W72 Trans am 80 Indy pace car Trans am 89 Trans am GTA |

|

#42

|

||||

|

||||

|

I'm guessing parts would have to be completely submerged in the solution to work, i.e. You could not submerge say half of the hood hinge, flip it over and do the other half. Would this be correct? Would the Gray parkerizing soulition offered by Calvan.com above ^ be the correct finish for our hood hinges?

The hinge on my Judge looks like it has a silver type finish (not sure on the finish, as I bought the car restored). On the other 69 GTO, I bought it from the original owner, it has a black finish on the hood hinges that look close to the black parkerizing finish shown in the Calvan.com site. The Judge was assembled in the Fremont CA plant and the other 69 was assembled in the Atlanta GA plant. Did different plants use different platings for hood hinges? Looks like I will try the black soulition kit from Calvan's for the bolts and fasteners. Any idea which way is correct for hood hinges? Thanks.

__________________

1966 GTO Vert automatic. 1969 CR Judge Ram Air III 4sp Pattern Car. 1969 GTO standard 350HP TH-400. 2006 GTO Phantom Black 6spd. 1972 Formula 455HO Ram Air. 1976 LE Trans Am 50th Anniversary Edition with T top. 1976 Formula 350. 1977 Grand Prix Model J 350. 1978 Trans am 400 Pontiac. 1979 Trans am 403 Olds. 1968 Olds 442. 1971 TR6. |

|

#43

|

||||

|

||||

|

Quote:

__________________

68 GTO 4-spd Convertible 78 S/E Trans am L78, WS6 Auto 78 S/E Trans am W72, WS6 Auto 79 10th aniv W72 Trans am 80 Indy pace car Trans am 89 Trans am GTA |

|

#44

|

||||

|

||||

|

Yep, anything I've ever coated, treated or plated pretty much has to be done all in one shot. So you'll need a pot big enough (Stainless) and enough solution to submerge whatever you want to treat.

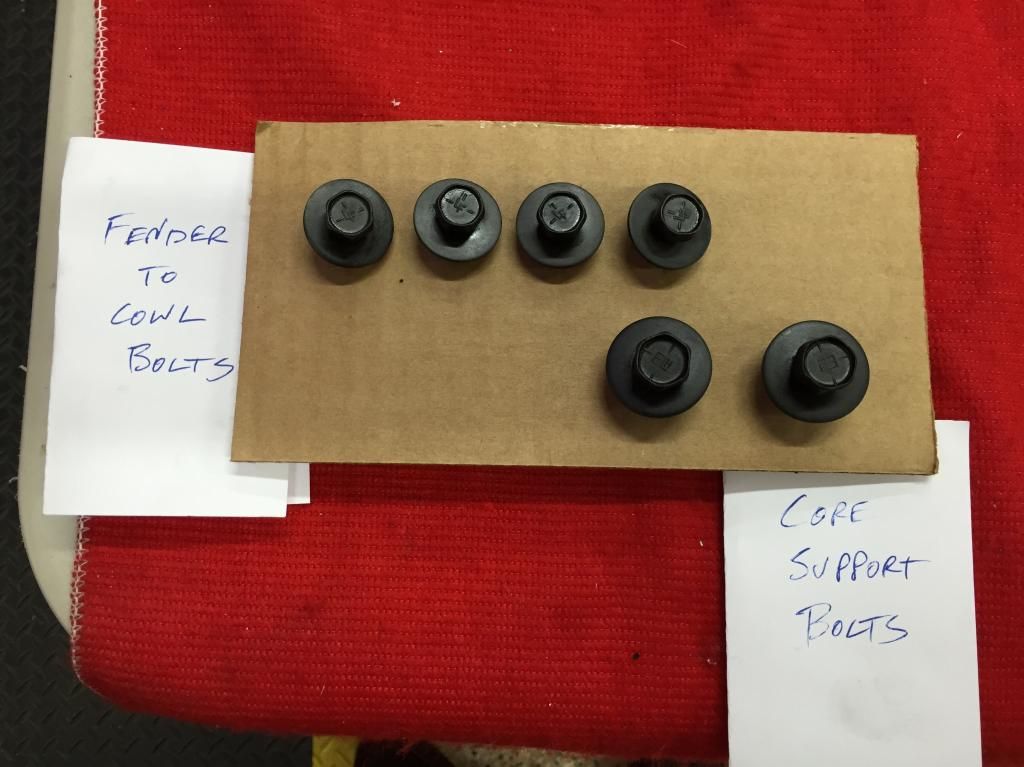

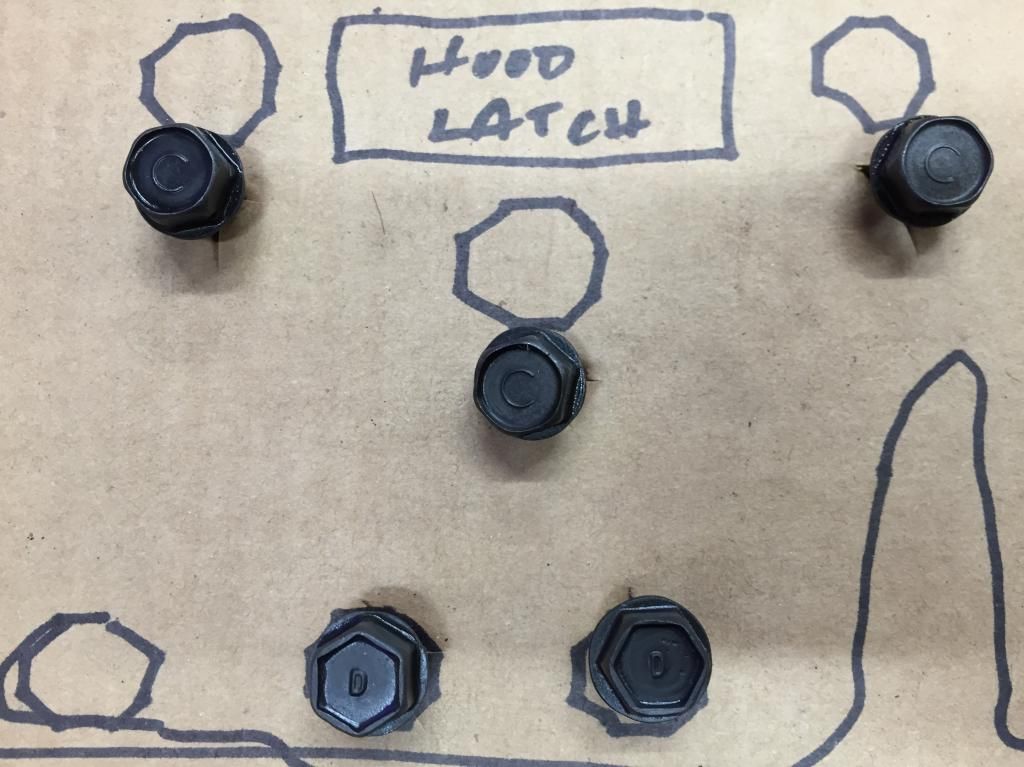

Zinc electro-plate, galvanizing, pretty much the same thing. A headlight bucket would require considerable current to plate. Probably have to rig up a car battery. Original bucket would have to be dipped in something like muriatic acid (careful with this stuff) to burn off the old zinc and remove all rust. Then probably 5-10 mins in a zinc bath and you'd have a fresh looking part. Below are pics of ... Some zinc electro plating, some control arm bolts done in manganese phosphate, some brake line brackets done in zinc phosphate, some zinc electro plated parts treated with chromate solution (hexa-chromate ... carcinogen) Did all this stuff at various times in my shop trying to come up with the right finishes. |

|

#45

|

||||

|

||||

|

wow, you really push the envelope. I don't have an issue paying somebody to do plating for me. I am far enough into the process with the 68 where one more round of clear, zinc & phosphate & I would be done. There's just nobody near Green Bay WI that does this on the smaller scales that will touch car parts.

__________________

68 GTO 4-spd Convertible 78 S/E Trans am L78, WS6 Auto 78 S/E Trans am W72, WS6 Auto 79 10th aniv W72 Trans am 80 Indy pace car Trans am 89 Trans am GTA |

|

#46

|

||||

|

||||

|

WOW dataway you did a fantastic job! I noticed in the 3rd picture some items seem shinier than others (for example the two hose clamps). It looks like one of the clamps seems to have a duller finish to it. Is this due to time in the solution? Thanks for the pics!!

__________________

1966 GTO Vert automatic. 1969 CR Judge Ram Air III 4sp Pattern Car. 1969 GTO standard 350HP TH-400. 2006 GTO Phantom Black 6spd. 1972 Formula 455HO Ram Air. 1976 LE Trans Am 50th Anniversary Edition with T top. 1976 Formula 350. 1977 Grand Prix Model J 350. 1978 Trans am 400 Pontiac. 1979 Trans am 403 Olds. 1968 Olds 442. 1971 TR6. |

|

#47

|

||||

|

||||

|

Charles .... now that I look at that photo, it was a comparison I did on Zinc plated parts showing on the left side of most pairs, parts that were "bright dipped" or "clear chromated" compared to parts on the right that were just taken right out of the plating solution.

In this case I think they were "clear chromate" .... you know the gold colored iridescent parts scene on cars back in the day ... the "clear chromate" is the clear version of that treatment. It was a solution I got from Caswell .... or Eastwood. Just a quick dip after plating leaves the part with a better shine, and the chromate coating stabilizes the zinc plating so it lasts longer, looks better etc. There are also solutions called "bright dips" .... which I've never been able to get to work well, and "brighteners" that you can added to the zinc plating solution that I find even harder to get to work well. It's a fun hobby for a while ... then you realize you are spending more time putzing around with plating than you are actually restoring parts or working on the car  However ... if you are stickler about using original parts ... in my case not just for correctness ... but because the "soul" of the car I have owned for 40 years is in those parts  , then it's worth it to mess around with this stuff. , then it's worth it to mess around with this stuff.

|

|

#48

|

||||

|

||||

|

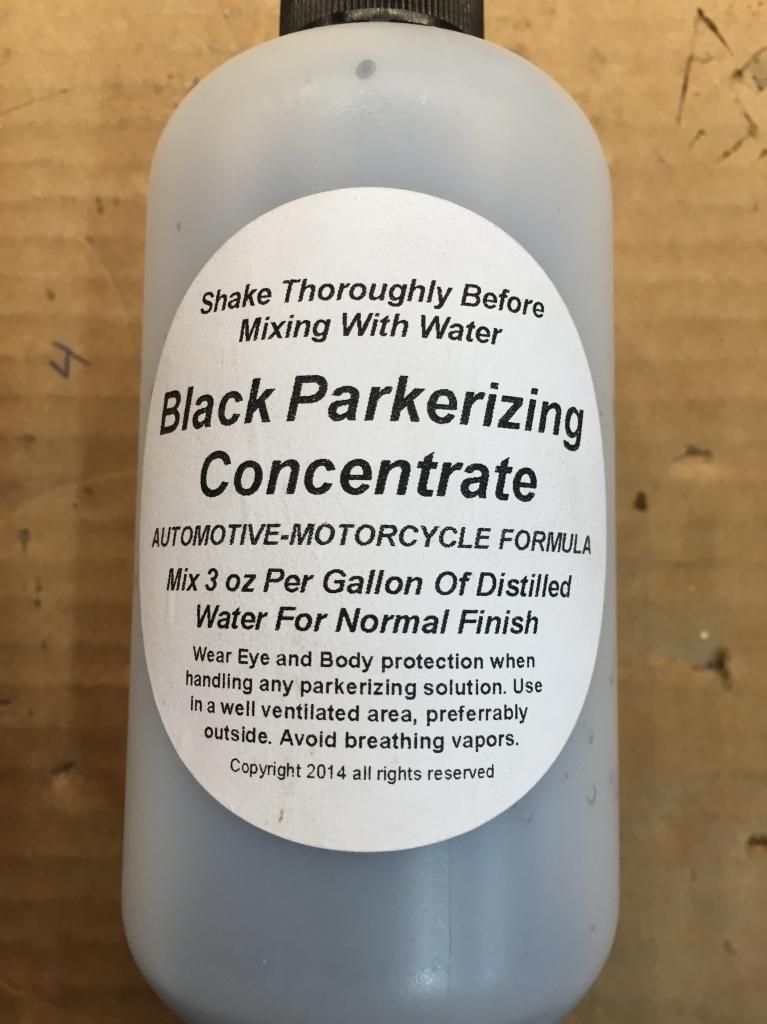

I have done a lot of manganese phosphate plating/parkerizing using the Calvan product and Palmetto's solution. The Calvan is better and more economical in my opinion, and you can get it on Ebay. It is pretty easy to do if you exercise reasonable care, follow the directions, and use common sense. It does not produce the dry black granular type coating shown in a few pictures. I have also used their grey phosphate solution and it too worked well. I have never tried Boeshield as an after plating coating, but have ordered some and am excited about trying it.

Regarding commercial plating, Colorado Plating does a great job on Gold, Silver and Black cadmium plating. They have a 6lb minimum, which is hard to meet, but the minimum price is only a $100 or so, and the turnaround is quick.

|

|

#49

|

||||

|

||||

|

Bob, what was your prep routine for those bolts? I haven't had any luck unless I bead blast everything before cooking it.

|

|

#50

|

||||

|

||||

|

Absolutely you have to bead blast. My process was:

1) roughly clean and degrease fasteners 2) soak in muriatic acid and then neutralize in a dilute baking soda solution 3) bead blast with glass beads following which fasteners should only be handled while wearing gloves 4) soak in solution of very hot water and heavy duty degreaser 5) rinse well in very hot water 6) immerse fasteners in boiling distilled water 7) transfer fasteners to 190 to 200 degree parkerizing solution which I typically mix 50% stronger than recommended 8) once fasteners have reached desired level of finish color transfer back to boiling distilled water to rinse 9) remove from distilled water, quickly blow dry with compressed air and immediately immerse in motor oil |

|

#51

|

||||

|

||||

|

Never thought to ask you this earlier: Have you done this on any of your other cars, or was the 78 the fist one? Curious how they hold up in a controlled environment? I'm guessing pretty well because even bare steel can hold up for years stored in the right location.

__________________

68 GTO 4-spd Convertible 78 S/E Trans am L78, WS6 Auto 78 S/E Trans am W72, WS6 Auto 79 10th aniv W72 Trans am 80 Indy pace car Trans am 89 Trans am GTA |

|

#52

|

||||

|

||||

|

Quote:

__________________

"The great obstacle to discovery is not ignorance...but the illusion of knowledge." Daniel J. Boorstein "Gas is STILL your cheapest thrill!" Your opinion of me is none of my business. |

|

#53

|

||||

|

||||

|

The bead blasting is a pain. The heads not so bad, but the threads are a pain. I wonder if a abrasive tumbler would work.

|

|

#54

|

||||

|

||||

|

I've had no problem with the formation of rust or deterioration of the finish, but then my cars stay garaged and don't get wet. Keep in mind these rusty, dirty, fasteners we are replating once looked this good or better. In other words, given the right amount of time and proper conditions even a factory finish bolt is going to deterioriate in appearance.

Dataway - I agree on the difficulty of media blasting bolt threads, but if you don't have a bolt basket you need to get one. It makes it a lot easier. Crank the pressure up to 120lbs and blast them in the basket while occasionally shaking. After so long dump them out in the blaster and touch up as and if needed. See link below. http://www.ebay.com/itm/Skat-Blast-S...552947&vxp=mtr |

|

#55

|

||||

|

||||

|

Thanks bob .... I'll be buying one of those

|

|

#56

|

||||

|

||||

|

Took advantage of the unseasonably warm weather yesterday and parkerized a few pieces. Did the Zbar and control arm cross shafts in gray, and did the carb idle solenoid bracket and tie rod sleeve bolts in black. It's interesting that the crimp nuts wouldn't go darker than gray even though hey were done at the same time as the other black parts. After the coating I saturated them with Boeshield in a foil pan and keep them "wet" for 24 hours before wiping down.

|

|

#57

|

||||

|

||||

|

Bob,

Your plating turned out really nice. The carb idle solenoid bracket was originally silver cad.

__________________

1968 Firebird 400HO convertible 1971 Trans Am 4-speed, white/blue Last edited by 68bird400HO; 12-18-2016 at 12:13 PM. |

|

#58

|

||||

|

||||

|

Looks great!

That finish looks very similar to the finish of the intermediate shaft on my 68, where it was protected by the rubber anyway. the rest was rust. I painted it black, but am thinking about doing the shaft in the grey color you created with the splined end in natural metal cleared in matt finish. Too much black under the hood on the 68 as it is.  Any neighbors stop over for a bowl of soup on your "cookout" ?

__________________

68 GTO 4-spd Convertible 78 S/E Trans am L78, WS6 Auto 78 S/E Trans am W72, WS6 Auto 79 10th aniv W72 Trans am 80 Indy pace car Trans am 89 Trans am GTA |

|

#59

|

||||

|

||||

|

I use a plastic strainer from Walmart. Worked well but i still spent way too much time at the blasting cabinet on just bolts and other hardware.

__________________

1968 Firebird 400HO convertible 1971 Trans Am 4-speed, white/blue |

|

#60

|

||||

|

||||

|

|

| Reply |

|

|