| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

||||

|

||||

|

Any tips or recommendations on installing a BOP one piece rear main with the crank in the block?

I have the engine out and stripped down to the shortblock, and would like to avoid disturbing anything that doesn't need to be disturbed. Should I just bite the bullet and pull the crank to install it? I believe my block was line honed or bored because it takes a .005 under timing set which I understand may complicate a successful seal install.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

| The Following User Says Thank You to Verdoro 68 For This Useful Post: | ||

|

#2

|

||||

|

||||

|

I would take the crank out. You need to measure the block and the cap to determine which part of the seal needs the most attention.

__________________

My Half AN Injun..... |

|

#3

|

||||

|

||||

|

I think that's probably the best approach if I want to be sure it's installed correctly. Any risk to untorquing/retorquing the mains (which are studs) and rods? Can I simply take it apart and put it back together with the new seal?

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

|

#4

|

|||

|

|||

|

I replaced the rear seal on a 70 455 a couple of months ago with the crank and rods still in the engine. One of my brothers spoke to Butlers about it and purchased the seal from them. They actually advised how to do it. It was a two piece seal. I took the mains caps off, then gently raised the back of the crank up. Pulled the rope seal out, and cleaned the seal area. Clocked the new seal how I wanted it and seated the crank and assembled like usual. Worked fine with no problems and was surprisingly easy.

|

|

#5

|

||||

|

||||

|

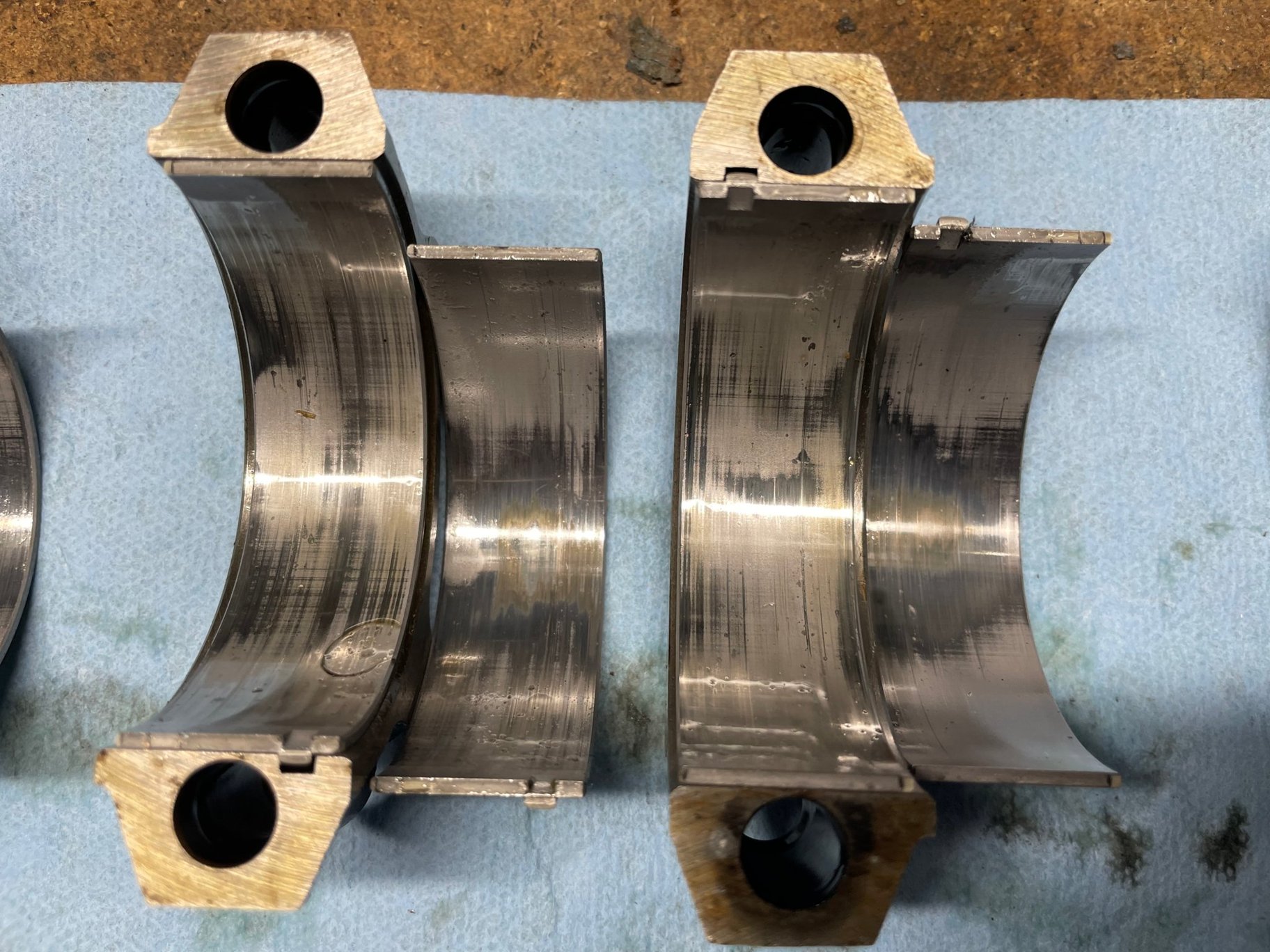

It has a two piece in it now. Based on the oil that was on it when I pulled the cap, I think my suspicions about it leaking were right. I pulled the caps off tonight and I'm not loving what I'm seeing in terms of the bearings, so it's looking like this might be a bigger project.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

|

#6

|

||||

|

||||

|

it looks like too much permatex was used on that seal. Im not surprised that its leaking by the looks of it . You're taking a chance installing the seal with the crank in because you dont know if the block was line honed to the point where the cap becomes shallower then the block side of the main. But yeah you can do it with the crank in . I haven't been so lucky doing it with the crank in.. Looks like those bearing are put in the wrong side . The holes go to the block not the caps ..

__________________

My Half AN Injun..... |

|

#7

|

||||

|

||||

|

I thought the same thing about the holes in the bearings - and the gobs of sealer around the main.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

| The Following User Says Thank You to Verdoro 68 For This Useful Post: | ||

|

#8

|

||||

|

||||

|

Good thing you looked into it and took the crank out. No big deal now . Just get some new bearings, put them in the way there supposed to be and definitely check those rod bearing. I cant imagine that there in good shape after running with the mains the way they are..

Good luck....

__________________

My Half AN Injun..... |

|

#9

|

||||

|

||||

|

The bearings must have oil holes on the block halves too .. or the engine wouldn't have run for 10 minutes I don't think.

__________________

I'm World's Best Hyperbolist !! |

| The Following User Says Thank You to dataway For This Useful Post: | ||

|

#10

|

||||

|

||||

|

^^^^ My clevite's did NOT have holes on both halve's......I happened to catch that when my son was putting them in as we were about to install the 1 pc rear seal!

|

| The Following User Says Thank You to 67Fbird For This Useful Post: | ||

|

#11

|

||||

|

||||

|

I got tired of the crap rope seal and constant leaking at the rear main seal. My engine is quite modded, and puts out a lot of crankcase pressure that just overpowers breathers so the oil will always push past the RMS and make a mess. So I was able to make a wire tool and carefully pick out and push the rope seal out at the top of the crank w/o loosening all the mains. Then slid in a Butler 2 pc seal. This helped, but I also added a Butler Crankcase Evac System. No more oil leaks.

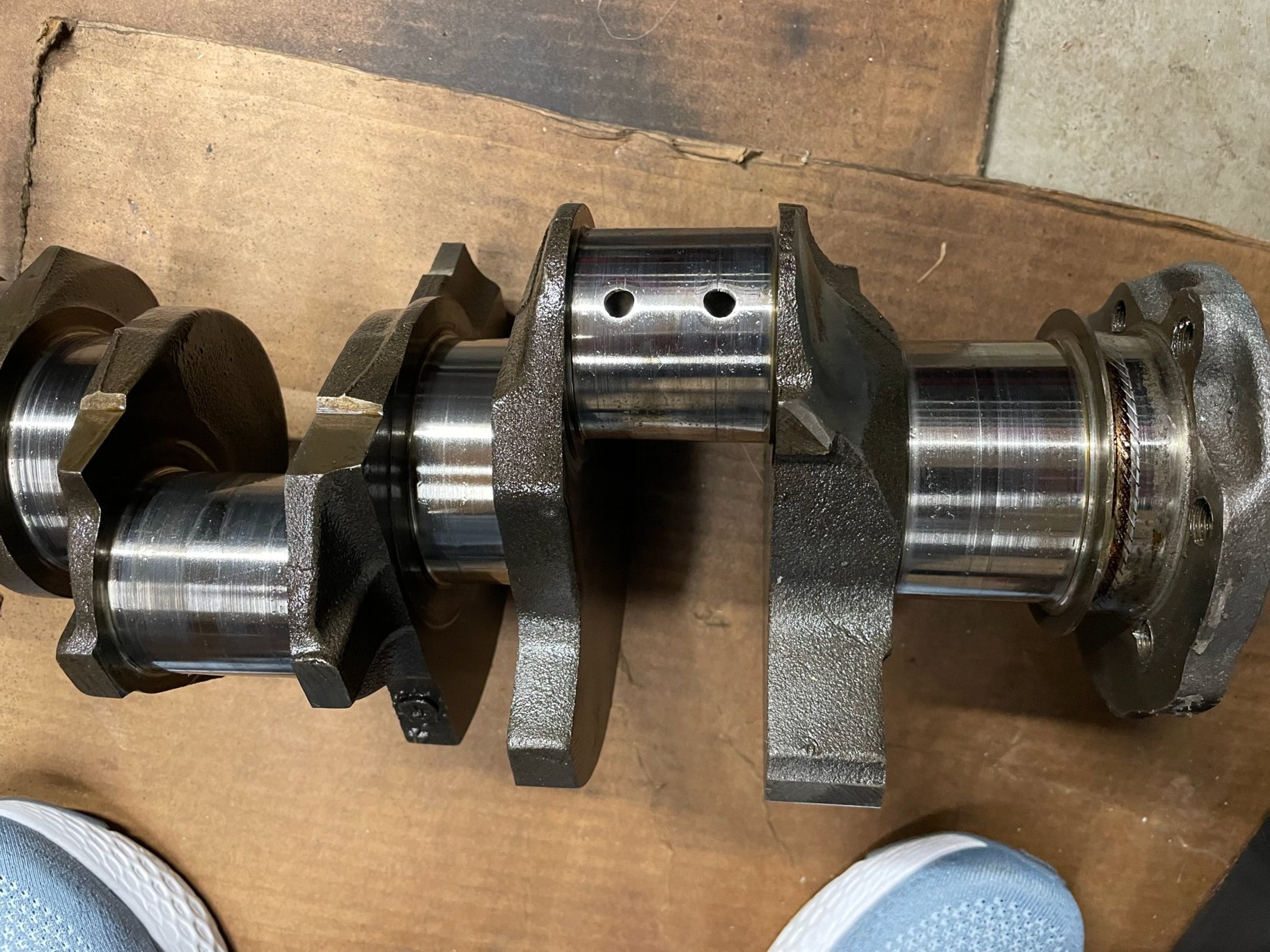

IMO that the discoloration is not a issue, the crank looks OK but not the bearings. SO new Clevites, new seal while you are at it, check the rod and main clearances with the new bearings, and your good to go. Last edited by Hesster1977; 01-13-2022 at 11:03 AM. |

|

#12

|

||||

|

||||

|

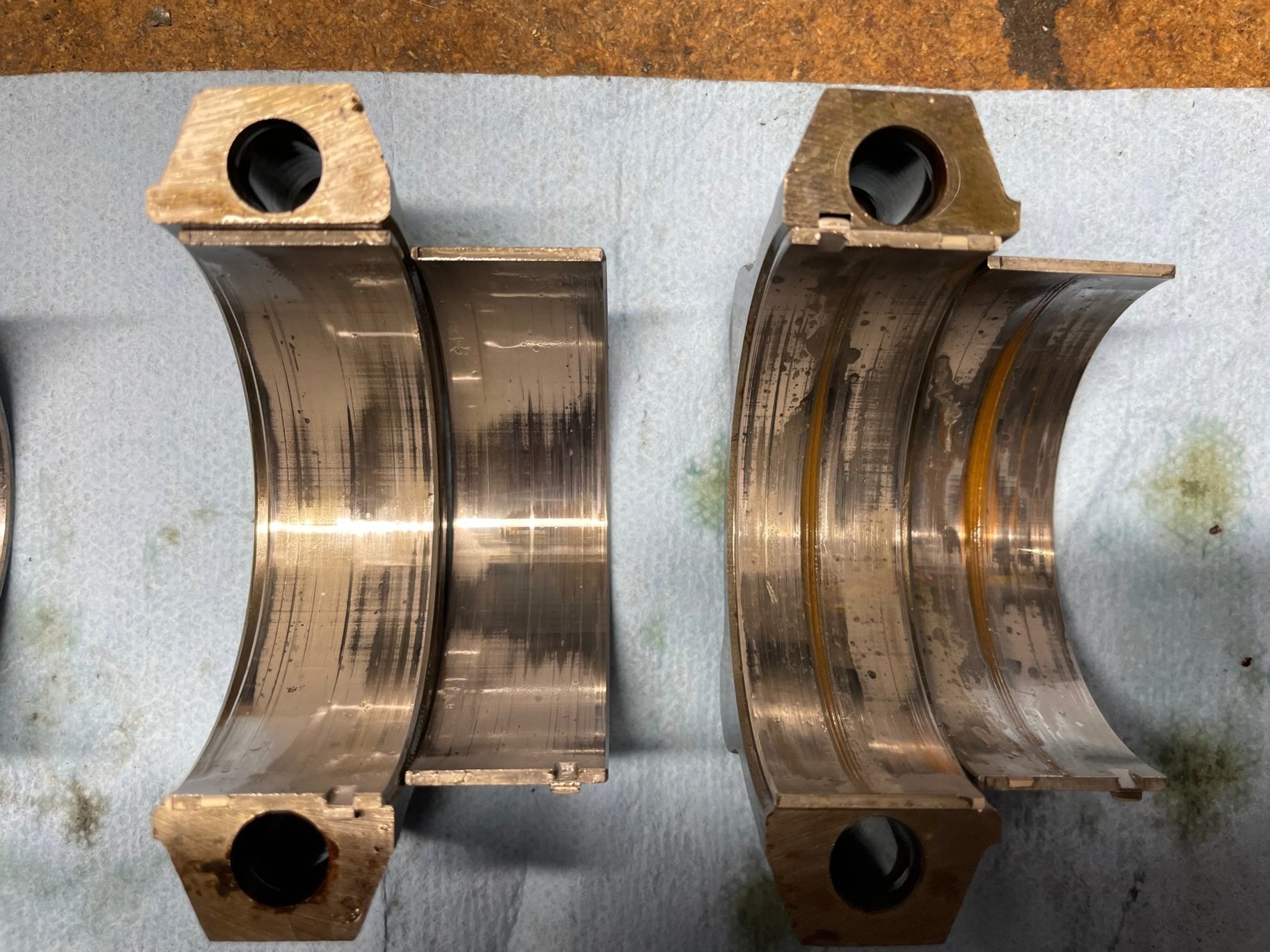

The parting areas on the the caps look really discolored .

__________________

My Half AN Injun..... |

|

#13

|

||||

|

||||

|

Digging through the forum, it looks like at some point in the past Clevite switched to having holes in both sides now.

https://forums.maxperformanceinc.com...71#post2949271 I could just put fresh bearings in and move along, but I'm worried this will happen again. I'll give the machine shop a call and see what he says. I'll need him to put new cam bearings in at minimum. Rods look like this:

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

|

#14

|

||||

|

||||

|

what does the rod side of the bearing look like ?

__________________

My Half AN Injun..... |

| The Following User Says Thank You to charlie66 For This Useful Post: | ||

|

#15

|

||||

|

||||

|

Yep, some bearing sets come with holes on both halves. No big deal. He just didn't take a picture of the main bearings in the block, but I'm sure they have holes too.

|

|

#16

|

||||

|

||||

|

Quote:

|

|

#17

|

||||

|

||||

|

Will get some pics of the rod end of the bearings, but I think they were about the same as the end.

Here's what my mains look like end to end. The middle three bearings are showing more wear. Not sure what that might indicate in terms of clearances or otherwise. The crank serrations might have contributed to the leak, I've heard they can be an issue. The seal on the whole is hard as a rock. I don't think whatever sealant they used was helping things. It seems to have shellacked over.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

|

#18

|

||||

|

||||

|

Can you show the bearings in the block as well . Im curious what they look like..

__________________

My Half AN Injun..... |

| The Following User Says Thank You to charlie66 For This Useful Post: | ||

|

#19

|

||||

|

||||

|

Looks like it had some trash run through it.

Are you sure it's been align honed or align bored?? |

| The Following User Says Thank You to Formulajones For This Useful Post: | ||

|

#20

|

||||

|

||||

|

Alright, here' s the carnage. Bearing caps are more roached than the tops, the rod ends are generally hammered.

Crank journals aren't too bad, but will likely need some cleanup. The crank is .010/.010 and the bearings are Clevite 77. Pretty sure I recall the machinist saying he line bored the block. It requires a .005 under timing chain. .010 is too tight, regular set is too loose. Got some giant pics for you all this time around so you can see the full glory. I thought I'd find a little wear, but nothing like this. Is this a combo of trash in the engine and detonation? It looks bad enough to where I don't think I'd feel good about popping some new bearings in and calling it a day.

__________________

Ken '68 GTO - Ram Air II 464 - 236/242 roller - 9.5” TSP converter - 3.55 posi (build thread | walk around) '95 Comp T/A #6 M6 - bone stock (pics) |

| Reply |

|

|