| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#21

|

||||

|

||||

|

Quote:

Of those that do the numbering scheme is not standardized. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#22

|

|||

|

|||

|

Since 0549 is now identified and verified as one of the numbers on build sheet in upper right corner (512044 96 0549) - the "49" from that "might" could relate to the "49" in front of 11-08 date code.

I couldn't make out the last digit as a 9 on my own. I checked through about 30 more 1970 Baltimore and Fremont Bsheets and only found 1 more that has a match in that respect. So maybe that is a coincidence since only 2 samples out of 30'ish have that match. Did find a higher number than 56 , 88 is now the highest i have. For example - this JVert ends with 0667 But schedule / date is : 88 01-09-70 DoE and Ship Date are 1-16-70 Went to Tennessee - from Baltimore |

|

#23

|

||||

|

||||

|

For Fremont cars, the number in front of the scheduled start date, is the number of production days from the start of the model year (in that plant) (01)-99, reset to 01-99, reset to 01-end of production.

If his trim tag does state 10B, it was probably stamped incorrectly or it did sit somewhere. One would have to compare other "body" numbers of that timeframe to know for sure. That J-vert has a body number of 6?!? |

|

#24

|

||||

|

||||

|

HFR, engine block is cast J159, heads are cast J179 and intake J319 and these dates falls right in between body date 10B and 11 - 18 - 69 date of execution?

|

|

#25

|

||||

|

||||

|

Tight date on the intake, but fine. Figure engine was assembled early first week in Nov. in the Pontiac, MI engine plant and a 1-2 day ship to Baltimore. Ram Air engines weren't needed too often. Date on distributor would be July. Carburetor would probably be close to early Nov. too.

|

|

#26

|

||||

|

||||

|

Thanks, carb date 3049, distributor 9G10.

|

|

#27

|

|||

|

|||

|

So it is still correct to presume that Kenth's car "date of birth" was Nov. 8 , 1969 ?

As far as using the Buildsheet and Invoice data to the best of our ability and knowledge. Going by all his supplied dates - there perhaps must have been a delay or holdback on the body shell involving the YZ engine. That must have been the first or second day that Baltimore began doing Convertibles at that plant. Michigan must have been doing them all before that ... on east coast anyway. Seems like i have another for body #20 too , from Balti or Fremont I have a set of #12 heads cast F249 - first time i can recall an F date on a new year cast engine part. |

|

#28

|

|||

|

|||

|

That BB 00xxx number on the Baltimore Bsheets is evidently a resetting number too.

Maybe it was the production build week running count for that body line ? It seems to stay under 00999. March 18 1970 with BB 00001 lol |

|

#29

|

|||

|

|||

|

March 1970

Sun Mon Tue Wed Thu Fri Sat 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 Be damd if i know what was going on .... Would they be assembling 600-700 units PER DAY ? |

|

#30

|

||||

|

||||

|

Interesting.

The body number of each body style should have reset at the beginning of the model year, to keep track of total units built. Maybe on their sheets, it just didn't matter what body it was. 600-700 units daily would be acceptable. I'm sure they were producing more than just Pontiac A-bodies. |

|

#31

|

|||

|

|||

|

In Baltimore 70 model - they were at minimum doing Chevelles too.

I only have a few Chevelle Balti sheets, and fair amount of GTO with a couple few Lemans. Mainly just guessing - that a given line would only do A-body cars ? Full size might have a separate line ? idunno Either way - if around 700+ total units a day were acceptable number - then that BB00xxx number "could" easily be the sequence number it went down the line that day - or some type of sequencing number for that day. the Job Sequence Number in upper left corner- 033985 -does appear to be the Baltimore Plant running total for model year to date . Have another GTO 4 days ahead of Kenth's numbered 030142 |

|

#32

|

|||

|

|||

|

Quote:

1.body tag date is build date/week and invoice dates assume finished car sat for weeks at assembly plant 2.or body build date then uncompleted body waited to be pulled for assembly. I believe number 2 .. And before others chime in.. yes, we all know some cars had to wait for transport to pick up, but not multiple weeks..If GM made 700 cars a day, I can assure you they shipped similar numbers per day. They had a rail line and over road pick up logistics arranged daily.. I guess what I'm saying here is I believe the Fisher tag is just that, a tag put on by Fisher,not GM. Which is why the Fisher tag doesn't have a vin correlation. Fisher made batches of body's of certain types(convertables,autos/4 speeds etc) and assembly pulled from body supply just like they pulled from engine,axle,tranny supply..The body tag cannot be used for assembly"born" date no more than the engines date can.. Granted body date was always closer to assembly date.. |

|

#33

|

|||

|

|||

|

I don't see much that i would disagree with.

Especially when almost every car has its own snowflake'ness. Particularly the special order customer cars that we mostly get involved with on the high end. The backlog of cars stored / shipped per day - whether they had waited 4 days or 10 days - would always be depleting and replinishing itself on a daily basis. The law of averages probably kept the plant storage lot at a happy medium or within capacity. Luck of the draw when a car ships. Over the Road Transporters have to have a full load or not much less. A dealer special ordering one car for a customer is going to wait longer than a dealer inventory order of 8-10 cars that can fill a transporter in one lick. Just a lot of variables exist on shipping and shipping dates. But sitting for more than 2 weeks at plant after completion would be really abnormal. Zone order inventory cars can give some false impressions on sitting at plant. Those mostly went right on out - and did their sitting at a zone storage lot. The ship date on those reflect when they left the zone storage lot to go to the dealer. I don't remember if i was in on your invoice discussion. But we gather more facts and better specimens all the time. 3-5 years ago answers might vary from todays answers. But most have a tight grip at this point. Backlog of bodies at Fisher would be self stabilizing too. Certain capacities built into design. I don't think the intended idle time for a welded shell was designed to be very long. Or the idle time from Fisher Finished to Assembly plant designed as being very long. All of those would have to be kept stored indoors most likely. But there would be overflow and backflow storage allowances up to degrees. Checks and balances were supposed to be well oiled and accounted before the build went into progress. But i'm sure sometimes they had to speculate on delivery of certain contents and take some things for granted from time to time. Finished cars can sit outside. When an example has the Buildsheet , Invoice, and trim tag available to scrutinize - it can be nailed pretty well. Enough of those type said examples can help form a happy medium. Early TA's don't seem to offer so many of those full data examples. Did the ID Number on your invoice happen to start with ZN or ZL ? My unfounded opinion would be the Fisher Side had more man hours into these cars than the Assembly Plant. But reality would seem more logical that the work load was really pretty evenly distributed Last edited by Baron Von Zeppelin; 02-25-2014 at 12:47 AM. |

|

#34

|

|||

|

|||

|

Different body types and different plants might have different factors .

But my understanding is that when a body left Fisher it was basically complete from firewall back. (no firewall items tho) Full paint inside and out, glass, carpet, seats, headliner, side panels, interior and back half wiring, tail lights etc etc... pretty much everything except steering column pedals dash and hvac Last edited by Baron Von Zeppelin; 02-25-2014 at 01:17 AM. |

|

#35

|

||||

|

||||

|

Quote:

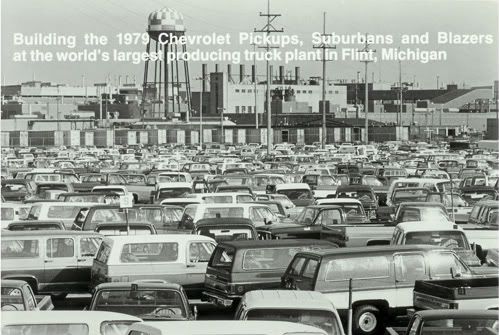

Typical line rate back then was 60 units per hour (with gusts into the low 70's at some plants). At 60 an hour for 8 hours a day, 2 shifts (assuming no overtime) that would be 960 units per day. The slowest line I've ever worked on in my life was 36 units per hour (Flint Line 2 - Blazer and Suburban), which would still be 576 units per day (no overtime). Plus: that's the reported final line rate. We would run the final line slightly faster so, if we had a "good day" (little or no downtime) we would overproduce, resulting in "free" units above what was required from central office. Also: upstream line rates were faster yet, in an attempt to keep the buffer/accumulators full and be able to keep the final line running (for a while) in the event of downtime in body shop or paint. So - "yes". Easily. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-25-2014 at 09:25 AM. |

|

#36

|

||||

|

||||

|

Quote:

K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-25-2014 at 09:34 AM. |

|

#37

|

||||

|

||||

|

Quote:

The Cowl tag corresponds to Fisher info only. The “build week” date is just that, and corresponds to the body build only (although, as stated earlier, we are not exactly sure what that means: start of body build? Completion of body build? Some significant pay point in the body build process? It could be something as boring/inert as when the body passed a particular build station and tripped a limit switch so that its progress could be tracked). It takes a day or so to weld the body up and get it through paint. Once it starts down the final line it should be squirting off the end in a few hours (within the same shift). Quote:

Quote:

Usually it would take a shift or two to do all the post processing and any repairs. Vehicles with no repair flowed right through; vehicles with a lot of repair (or "heavy" repair) sometimes got all the gas burned out of them shuttling them to the various repair stations. Two weeks would be extreme, although we do hold pre-production jobs for up to two weeks to de-brief and post process (mostly software updates, which they would not have had to do back then). Occassionally we would “lose” a job somewhere in the back yard. Usually we would build a replacement vehicle and ship that and the original “lost” vehicle would turn up in some remote corner of the lot at model change, or some other time when the shipping backlog was worked down. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-25-2014 at 09:56 AM. |

|

#38

|

||||

|

||||

|

Quote:

Welded shell - a little less than a day Through paint - a little less than a day so there's a little less than two days Down final line: from body drop to end of line is a few hours Completed bodies are kept inside, at the Pontiac plant there was an eight lane 'body bank" that bodies were drawn from depending on final line workload balance and/or part availability. Here is video of the Pontiac body bank (at the 2.24 mark) from the "Pontiac Pours it On for '71" series: http://www.youtube.com/watch?v=r6HDXJ0P6Xk Completed cars sat outside, as shown in my pictures on the first page and above. K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 02-25-2014 at 09:37 AM. |

|

#39

|

|||

|

|||

|

Keith you are for sure one of the priceless contributors for us on this type stuff.

Glad we are able to have someone who can give accountable confirmations from time to time. Kenth its looking like your Judge went down the final assembly line at Baltimore on Nov. 8 , 1969. 687th car that day 33,985th car that year (Baltimore) 221,375th Pontiac car invoiced for 70 (PMD) 2-3 weeks between inception at Fisher - til it hit the big house. Checks and balances evidently got out of whack at the big house and it got held before it could make the next jump. Could have been a shipping container of radiators got misplaced and couldn't be found ... just an example. The bean counters must have shown everything was in inventory - or fully expected inventory arrival of some component. But the bean cookers didn't have it or couldn't find it when the moment arrived. Whatever IT was ... Unless there was some labor turmoil at Baltimore in second half of October idunno |

|

#40

|

|||

|

|||

|

And yes BVZ.. you were one that was telling me my assertion that body tags dates were not build dates was wrong. Technically we could have a correct car with an engine,carbs etc dated between the body tag date and the invoice date,doubtful but we could. I was told on this 70-73 blog that I did not know what I was talking about and that cars sat for weeks after being built and the body tag was the build date.. Yes, I was amused. Same group of guys, VBZ and Sweden guy, the same week on the 70-73 blog discussing an EES Quadrajet that ..to quote" I should shut up and learn from those who know about Quadrajets"..little did they know, and I sure wasn't going to tell them.lol..I was having too much fun being told I knew nothing about Quadrajets,FYI ... I am the one who did the 68 Firebird RAll that has broken all the records(525hp out of box with only idle speed adjustments), plus the same guys two RAIV's as well as about 6-7 other RAIV's.I'm quite picky on which cars I work on.... Known for my interior tuning ability plus,something few do, my exterior cosmetic correct resto.. SO yes, seeing this blog brought back funny memories of similar posts a couple yrs back..

Long and short..just because someone posts authoritatively doesn't mean they are correct.. |

| Reply |

|

|