| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#61

|

|||

|

|||

|

Does that fuel pump have the spring and diaphragm in the bottom half??? If so it could be boost referenced. It sort of looks somewhat like the Corvair pump and that one could be boost referenced.

|

|

#62

|

||||

|

||||

|

My 347 [now a 370] has a forged crank.

__________________

Roll around in the excitement |

|

#63

|

||||

|

||||

|

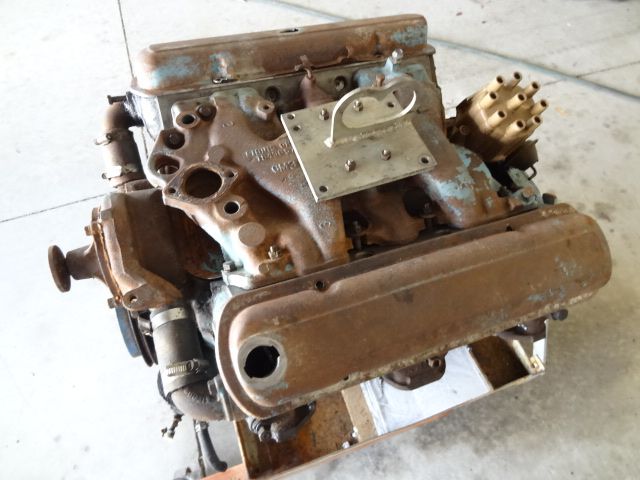

.....to start assessing the condition of this old 389.

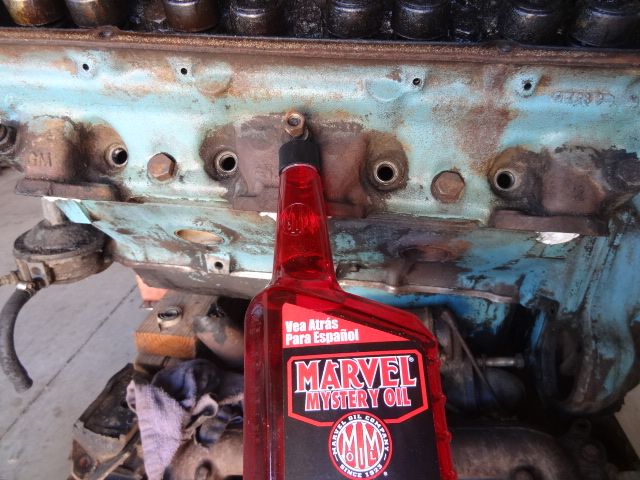

Pulled the valve covers and saw a fair amount of sludge buildup, pretty much what I expected to see on a 56 year old engine that had no PCV system for it's entire life. All in all not too bad nor too excessive, drivers side shown here.  The passenger side clearly has some thicker sludge buildup compared to the other side.  Someone must have removed the driver's side valve cover fairly recently during the engine's lifetime and cleaned out most of the sludge from the underside of the cover.  I had soaked both breather caps in Simple Green for about a week, they're now quite clean inside after a good rinsing. They were completely clogged with crud, obviously contributing to the sludge problem. The larger drivers side breather has horsehair inside, the passenger side looks to be filled with stainless steel wool.  I removed the carb and saw that a small amount of water had made it into the intake manifold. Not enough that it ran down the intake runners and into any of the cylinders, just enough to leave a small rust puddle right under the throttle plates.  The topside of the throttle plates show some surface rust buildup from the water ingress, but nothing too excessive that won't clean up fairly easily.  Bottom side of the throttle plates look pretty clean, looks like the carb had been recently gone through not long before the car went to salvage.  The carb is actually a 1964 unit from a 283 HP 389 with A/C and auto trans. Pretty much a perfect application matching replacement for the 280 HP 1958 A/C auto carb, only 5 years newer.  Spark plugs (Bosch WR9FC) must have recently been replaced, they look almost new. Cylinders look to be pretty healthy, but the fact that they were not run for very long doesn't really give me a true indication. Cylinders 1, 3, 5, 7.  Cylinders 2, 4, 6, 8.  I'm going to lube up the cylinders and begin freeing up any sticking piston rings with a little dose of Marvel Mystery Oil.  I used this 3oz oil bottle to squirt a little into each cylinder, trying my best to evenly distribute the contents of the bottle between all 8 cylinders. I'll do the same thing again in about a week to give it time to soak in.  I lubed up all of the rocker balls and pushrod tips with some 10W-30 motor oil. Surprisingly enough, the distributor not only turned back and forth freely after loosening up the clamp, it popped right out after removing the clamp. No stuck distributor nightmare for me, needless to say I'm pretty happy about that!   Overall the carb didn't look too bad, it just needed a good external cleaning.    After about a half hour of going over it with a toothbrush and some Simple Green it came out looking pretty good.      It took a little wire brushing to get most of the rust off of the top of the throttle plates. The way I see it, this carb's a runner now.  I did manage to pick up a cast iron 1960 stick shift bellhousing in good condition from a fellow PY member. In order to use a stronger modern stick trans you need to use a 1958 -1960 bellhousing, any of the 1955 - 1957 bellhousings just won't do if you want to use a 'good' trans. Using a stick trans behind the early 389 eliminates the need for any kind of adapter. If you want to run a modern auto trans like a TH400 you would need to spend about $700 for an adapter from Wilcap.     Here you can see where the starter mounts to the bellhousing, there's no way to bolt a starter to the 1959 block. Let me tell you, this sucker is heavy!

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#64

|

|||

|

|||

|

If the pressure suction road draft system is maintained properly it's just as effective in ventilating the crankcase. Most people who do try to take care of them miss ( and for good reason-it takes too long and can be messy ) the part about after cleaning the breathers (3) in solvent and letting them drip dry/blow dry, they are then supposed to fill them up with a light oil and let them drip dry again.

|

|

#65

|

||||

|

||||

|

.....so I can clean and reseal it. I also really need to clean out the valley pan that is surely packed with sludge before firing up this 389.

The factory 2-barrel intake takes the large base Rochester carb. To remove it you must pull it towards the passenger side to get it off of the 4 studs that retain it on the drivers side, rather than pull it straight up.   As expected there's plenty of rat droppings and debris sitting on top of the valley pan.  The intake ports look fairly clean with just a thin coating of black deposits. There may have been a vacuum leak from the look of some of the intake gaskets. Cylinders #2 and #4.  Cylinders #6 and #8.  Cylinders #3 and #1.  Cylinders #7 and #5.  A small amount of water did make it into the #2 intake port, but luckily enough the valve was closed so water didn't get into the cylinder. I'll close the valve and pour a little Marvel Mystery Oil into the port to clean it up a bit, a few flakes of rust should be easily digested without hurting anything.  I stuffed the ports with paper towels to get ready for all the gasket scraping.  The exhaust crossover uses separate steel shim gaskets to seal it on each side, there's actually a formed lip stamped into the gasket that fits inside the port.   Scraped and wire brushed clean, pretty much ready to accept some new gaskets. I had to get these areas as clean as possible in order to minimize the amount of crud that will drop into the engine while removing the valley pan.   The sludge accumulation isn't too excessive for a 56 year old engine, however there were a few large flakes that had come loose from the underside of the valley pan resting in there. After many years of sitting the thin layer of sludge just dries out and flakes off. Now I can assess the condition of the cam and lifters, there's sure to be a couple of cam lobes that are going flat.  The valley pan will eventually come clean after a good long soaking in some cleaning solution.  The top side will need to be bead blasted, after masking off the underside and any openings in the top side to keep the blasting media from getting inside.  This opening is where the road draft tube connects, as you can see it's packed with crud.  Putting the 389 to bed for the night.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#66

|

|||

|

|||

|

You'll never get that engine clean enough to fire up, think what's in the crankcase and especially in to coolant and oil gallery passages. I would take it all apart and hot tank it all.

|

|

#67

|

||||

|

||||

|

I disagree. I pulled a 350 out of storage that was almost as badly sludged up. I pulled the oil pan and valley pan and used WD-40 and a brush to clean up all of the grease and grime that was inside. Used a little WD-40 and Simple Green while running the oil pump with a drill as well. It wasn't the prettiest engine but it ran great. After putting a new cam in (flat lobe) and timing chain in and putting it back in the car I did a lot of back to back oil changes. It's been running for 7 years now in a car with 60psi oil pressure cold and 20psi hot, no hint of trouble.

Granted, I do agree that pulling it all apart and hot tanking it is the CORRECT way to do it, but that doesn't mean he can't get it running fine as-is with the proper prep if nothing else is wrong. |

|

#68

|

|||

|

|||

|

Glad you are continuing this thread. Maybe later on you can show off where the "beef' is compared to newer 400/455 blocks.

FYI Gavin and I are refining adapter drawings that will allow the modern BOP or chev bell pattern automatics to be made (either at home or a local fab shop) at significantly less cost than Wilcaps or Bendstens adapters. As a plus it doesn't require thick flywheel spacers or a Mopar starter. We will have a thread with complete info/instructions/video, hopefully early January 2016. |

|

#69

|

|||

|

|||

|

Quote:

|

|

#70

|

||||

|

||||

|

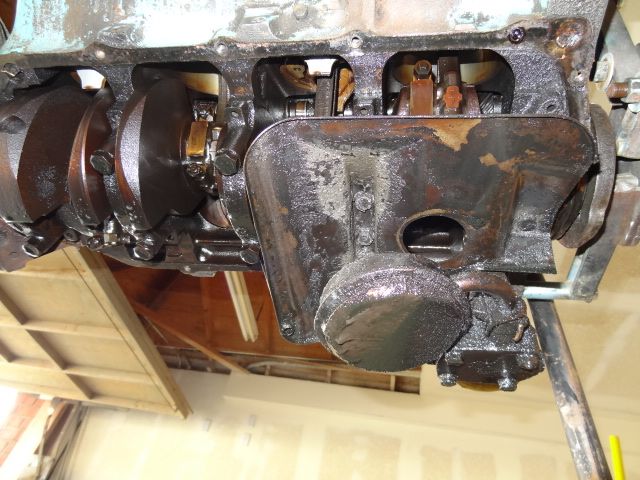

After a few good long soakings and several rinsing sessions the valley pan came out pretty clean, probably 95% of the accumulated crud was cleaned out of it.

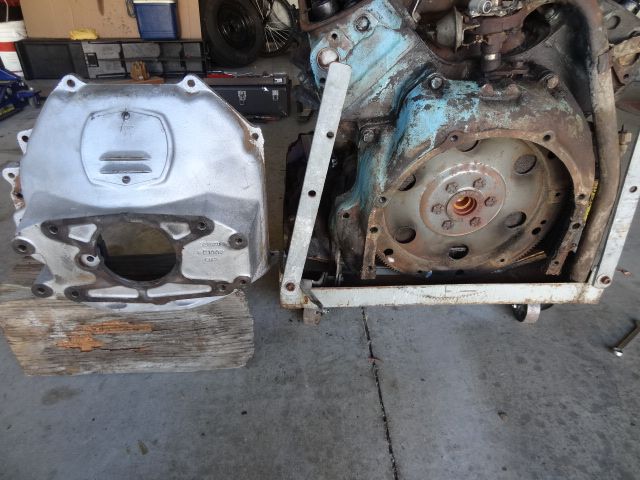

Going to put the intake back on so I can use my lifting plate to put it on the engine stand. I want to remove the oil pan to clean it out and check on the condition of the bottom end. First the valley pan.  Now the intake.  Lifting plate installed, ready for the engine hoist.  Warming up the sump a bit with a heat gun to help the cold oil drain a little better.  Dirty old oil - it looked like 4 or 5 quarts drained out, a good sign.  Pulled off the auto trans flex plate and bellhousing. A bit of a strange arrangement compared to the later Pontiac design, first you must remove the flex plate and drop it straight down out of the bellhousing. Next there is a rear sheet metal shield that attaches to the bellhousing with two bolts as well as the two rearmost oil pan bolts, the shield also serves to support the rear oil pan sealing area. After all that you can finally remove the cast iron bellhousing.  Up on the engine stand, ready for oil pan removal as soon as I get some time.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#71

|

|||

|

|||

|

Take the intake and the valley cover off before you flip the engine and remove the pan for obvious reasons.

|

|

#72

|

||||

|

||||

|

Thanks, that was my plan. They only went on temporarily to simplify the lifting operation.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#73

|

||||

|

||||

|

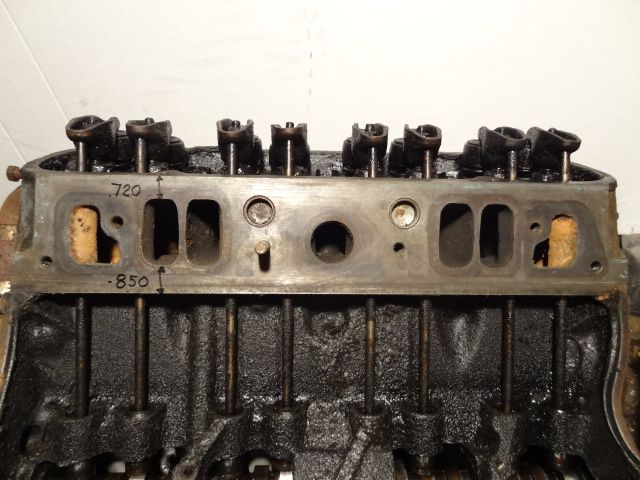

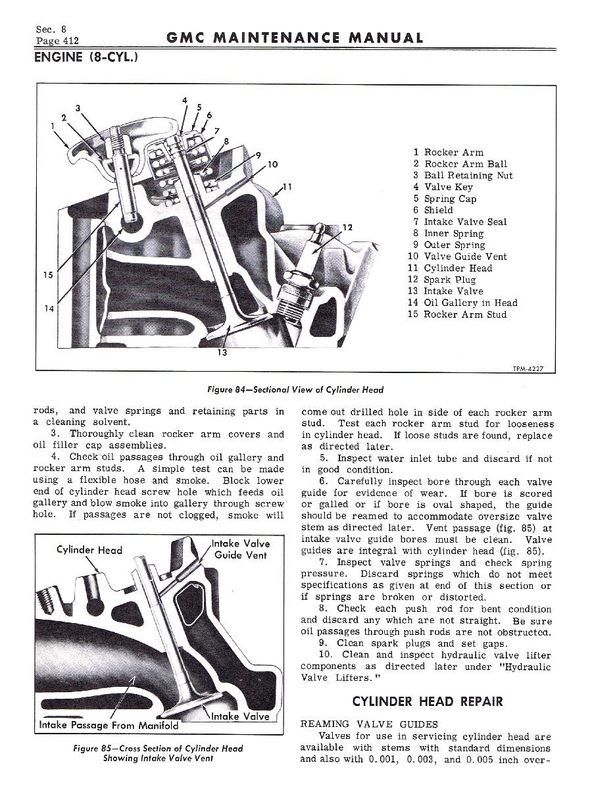

Here's a closer look at some of the unusual features of the casting # 531395 1959 heads, all 1959 engines used this head casting.

Valve sizes are 1.88" intake and 1.60" exhaust.  The intake and exhaust crossover port placement is exactly the same as the 1961 - 1964 heads. The bolt pattern is identical as well.  For the sake of intake and crossover port comparison, a 1964 9770716 389 head is pictured at the top, a 1970 #13 400 head below. Port entrance size is nearly identical between the two heads, 2.050" X 1.110" for 1964 and 2.070 X 1.100" in 1970.  Here is a 1964 intake gasket laid over the 1959 head. As you can see the water ports are in a completely different location.  Here's the 1959 intake manifold.  There isn't much material cast into it in the exhaust crossover region, it uses studs, castle nuts and large thick flat washers to clamp down on and seal the ports in this area. It doesn't use a thermostat bypass port to the timing cover.  1964 intake, showing a lot of added material around the exhaust crossover flanges and different water port placement.   Here is where we will see one huge difference between the 1959 (1955 - 1960) and the '61 - '64 heads. The intake ports are almost the same exact size as the '64 head at 2.050" X 1.100", but the cylinder head itself is .320" taller than the later heads. The valve cover rail is higher, both cylinder heads have the same .850" measurement from the cylinder head deck to the bottom of the port. However the '59 head measures .720" above the port compared to only .400" for the '64 head.  Note that since the valve cover rail is so much higher on the '59 head it doesn't have the small bump cast into the roof of 2 of the ports to keep the valve cover bolt hole from breaking into the port roof like on the '64 head. Also take note that there are no openings on the intake side of the head that lead to the crankcase like on the later heads.  Again for comparison here's the round casting protrusion in the roof of the two end intake ports on the '64 head, put there to seal off the bottom of the tapped holes for the valve cover bolts.  Another unusual feature that likely was the main reason the heads were so much taller, are the 4 intake valve guide vent holes in the side of the head just below the valve cover rail. These were put there to provide a vacuum break for the valve guides, to prevent them from sucking oil down into the combustion chambers. These tall heads must have made these early engines look just a little bigger and wider than their later cousins.  Vent hole diagram from the factory manual.  A closer look at the vent holes.  1959 was the last year that Pontiac used reverse cooling, pumping water first through the front of the cylinder heads and then down through the block. Here is one of the water fittings on the front of the head.  A view of the rear of the head, better showing the placement of the water channel. The small soft plug above the water channel blocks off the ends of the oil passage cast into the head that feeds oil to the rocker studs. All Pontiac heads oiled the rockers through the rocker studs until the introduction of the '63 -'64 9770716 heads, the only exception being the early Super Duty heads.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#74

|

||||

|

||||

|

I picked up a very nice 1959 Tri-Power intake today.

1959 was the 3rd year that Pontiac offered the Tri-Power option, however the large-base Rochester carbs were used as the secondary carbs for the first time in 1959. Now to find a center carb and a front carb, I already have a rear carb.     Casting # 532422  Date code 'L 15 8' (December 15th 1958)

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#75

|

||||

|

||||

|

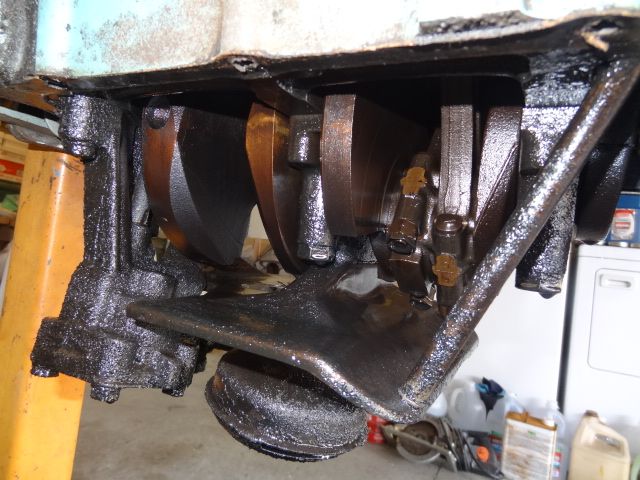

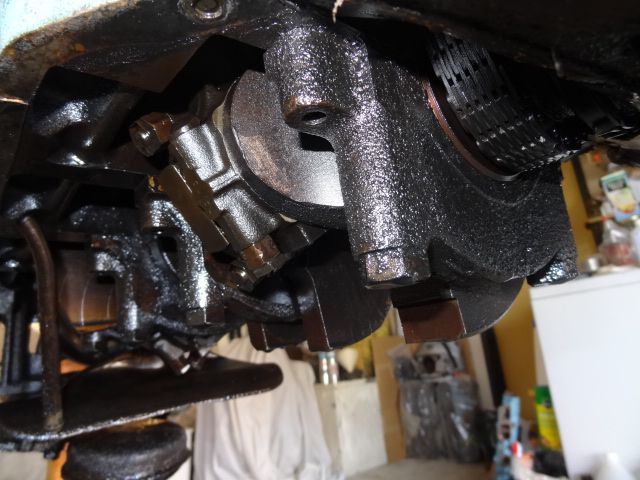

Decided it was time to drag out the ol' 389 and drop the pan today. Topped it off with a nice '67 326 2-barrel air cleaner I had laying around just for grins.

The pan practically fell off after removing all of the bolts, the gaskets were old and tired. There was a pretty big leak going on at the rear of the pan from what I could see.  The sludge buildup in the sump was pretty thick, anywhere from 3/8" to 3/4" depending on the shape of the sump area. The drain plug was almost buried in sludge.  Here's what I harvested from the sump, a pretty good amount.   One of the features of the older Pontiac engines was this 'floating' oil pump pickup. Perhaps it was designed to keep the pickup above the layer of sludge that older engines were known to accumulate over time, surely the engineers knew that non-detergent oils and leaded gas would be laying down a decent amount of sludge during the engine's service life.   Here's a look at the windage tray/sump baffle, a design that was used up through 1964.   Very thick #1 main cap, looks to be at least 1/4" thicker than on '61 and later engines.  The connecting rod nuts are backed up by a sheetmetal locking nut, an interesting feature that I didn't expect to see.  Here you can see the heavy webbing cast into the block on the passenger side oil pan rail area, a feature that would disappear from common production blocks after 1960.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#76

|

||||

|

||||

|

The exhaust manifolds cleaned up nicely.

Pontiac exhaust manifolds have a nice free-flowing design, much less restricted than the standard exhaust manifolds of most other makes.   I'm particularly fond of the driver's side manifold with the center outlet, purely from an aesthetic standpoint. A pair of these would look great on a fenderless late '20s or early '30s roadster with an open engine compartment.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#77

|

||||

|

||||

|

B-Man:

In case you'd rather not try to clean up that oil pump pickup, I have a new, in the GMC (not Pontiac) box, part number 516085 pickup & screen that I'd let go for $25 + shipping. It has a small amount of surface rust. Pontiac used this exact part number from 1955 through at least 1960.

__________________

My Pontiac is a '57 GMC with its original 347" Pontiac V8 and dual-range Hydra-Matic. |

|

#78

|

||||

|

||||

|

I've never seen those thin locknuts on any '57-59 engine. To quote the 1959 Pontiac shop manual- "Torque the rod nuts to specified torque. The nuts are self locking and require no washers or cotter pins".

Did all '59 passenger side exhaust manifolds not have the center ports divided? I didn't remember that.

__________________

Anybody else on this planet campaign a M/T hemi Pontiac for eleven seasons? ... or has built a record breaking DOHC hemi four cylinder Pontiac? ... or has driven a couple laps of Nuerburgring with Tri-Power Pontiac power?(back in 1967) |

|

#79

|

||||

|

||||

|

I cleaned up my rear carb today and took a few pics.

First off, here's what's left of the original foil ID tag. Part number 7013065 tells us it's a rear carb used from 1959 - 1962 on both manual and auto trans 389 engines.  Top view of the carb where you can see the large vacuum diaphragm that was used to actuate both the front and rear secondary carbs depending upon engine demand (wide-open throttle).  That vacuum actuator is huge (camera perspective makes it look even bigger), it has to be in order to pull those two carbs wide-open.  A look at the linkage from the actuator to the throttle shaft.   I removed the actuator since I'll probably be using 1965 - 1966 manual-trans mechanical linkage instead. All Pontiac Tri-Powers had vacuum actuated secondary carbs up until the introduction of the 1965 GTO stick-shift engines. All GTO auto trans Tri-Powers were vacuum actuated. A lot of Tri-Power owners didn't like the scary one or two seconds that the vacuum-controlled secondary carbs took to close after lifting off the throttle, and who could blame them. Many were converted to aftermarket mechanical linkage and some owners had the Tri-Power setups removed altogether and replaced with a standard single 2-barrel or 4-barrel.   I checked the angle of the throttle plates at wide-open position and found that they don't open all the way. Very likely this was engineered into the setup to keep from adding too much airflow for the engine to handle.   Here's the stop on the side of the throttle body.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

|

#80

|

||||

|

||||

|

I've been informed by a more knowledgeable PY member that what I have here is a front carb, not a rear carb.

From the positioning of the vacuum diaphragm I kind of suspected it, but wasn't sure. No matter, I'm just happy to one of the three that I need for this setup.

__________________

1964 Tempest Coupe LS3/4L70E/3.42 1964 Le Mans Convertible 421 HO/TH350/2.56 2002 WS6 Convertible LS1/4L60E/3.23 |

| Reply |

|

|