| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

||||

|

||||

|

This is a curiousity question about technology change in the industry.

25 years ago, I visited a prototype mechanic in the engineering garage. He asked me to come with him to the tubing bender area. I watched him drop in a disk and then feed in a certain size of metal tubing. After a while he had a strangely configured tube that would thread into the chassis of a prototype car. The questions: What was done to make these lengths of tubing before Cad" Is tubing bent in the same way now? What would you do in your garage if you had to make your own? Regards citydesk175 BTW Take this as a starter for other processes |

|

#2

|

||||

|

||||

|

Alright, I figured out the answer, My thirst for knowledge has been defeated and aided by the miracle of the 21st Century: "context-sensitive advertising"

Look at the top of this thread and note links for "Universaltube.com", "mtechsales.com", "ideas-cube.com",and "trysurplus.com" and more at the bottom. Google will own the world with "context sensitive advertising" and it will be ready to post an appropriate ad by your content the moment you even think of the content. Thanks to the links, we now know how to bend tubing.... no questions asked. Regards Citydesk175 |

|

#3

|

||||

|

||||

|

I have a couple thoughts:

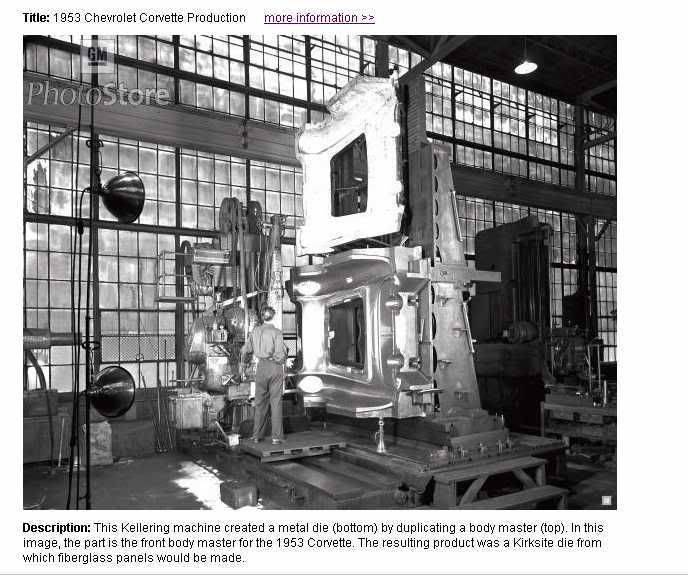

You are correct; we do currently use CNC benders to create brake lines, fuel lines, etc. However, for short runs of prototype parts or if there is an urgent need we do still bend lines by hand; three view drawings are generated and a small "nesting fixture" (ie, wood blocks with grooves in them) is made. Each bend is made using a hand bender until it lays in the fixture without gapping. On a related note, how were stamping dies duplicated before CNC? Good question; here is the answer: on a "Keller" machine. A Keller is a tracing machine - the completed die is positioned on top and the work piece is fastened below. The top stylus traces the pattern and the bottom cutting head machines the piece as you go. One of the things they would do is line the pattern piece with a special type of masking tape, to give them the thickness of the tape (approx .007") as cushion so they could finish/polish the die by hand. Even at the time of his passing Dad would refer to masking tape as "Keller tape"... Last one: I was just reading in the thread about the old Packard plant; it was talking about the "engine set" operation. Apparently it was a big breakthrough when they adopted the use of an engine "hoist" (what you and I would call a chain hoist) and that it replaced the three burly men who used to set the engines in the chassis by hand...  Keller machine: This particular photo was taken at the GM Assembly Research Center, which stood on the north edge of the property at Chevrolet Flint Assembly. This is also where the first 300 Corvettes were built, and the building was only recently torn down.

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#4

|

||||

|

||||

|

John V reminded me of a couple more:

"Fortran" punch cards - used to run the old computers (like you get from PHS). Anybody remember the old "microfiche" readers? Those blue, stiff transparencies that you put in a special machine to be able to read? Lastly - here's one that we still do the same way. The "mainframe" system that we use here in GM to maintain our parts releases I'm sure is the same one that was originally designed when computers first came into industrial use...  K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#5

|

||||

|

||||

|

My buddy George Watt was the reigning EXPERT on gears at the Tech Center in Warren MI and that included the Warren Gear and Axle plant too. He told me he had a bedroom filled with boxes of Gear cutting Fortran programs that were and prolly still are "State of the art"

George was unwittingly part of a running joke on rookie security guards: Experienced Guard: "Get his name and let him drive out" Rookie Guard: "Whats your name?" George Watt: "Watt" RG: (louder) "Whats your name?" GW: "Watt" EG: "Let him go" George was an engineer who made money for GM because his time was sold to other companies like the Tank Plant etc George spent a year preparing for retirement by trying to get 5-6 engineers up to speed on what he alone knew, Sadly he died before he could retire. He took gears and transmissions seriously and we are the beneficiaries. Thanks George CD |

|

#6

|

||||

|

||||

|

Interesting stuff- thanks, guys.

What was "Kirksite" that the 'Vette dies were made from? "Punched cards"- do I need to tell you what the acronym EBCDIC stands for? For that matter, some people might need to be told what "ASCII" stands for? If you need to do any assembly-language programming on an IBM 360 model 50 (via punch cards, of course), I've still got the assembly-code manual!

__________________

Anybody else on this planet campaign a M/T hemi Pontiac for eleven seasons? ... or has built a record breaking DOHC hemi four cylinder Pontiac? ... or has driven a couple laps of Nuerburgring with Tri-Power Pontiac power?(back in 1967) |

|

#7

|

||||

|

||||

|

LOL -

We always attributed this quote to George: "...a singing axle is a happy axle...".  Kirksite is an aluminum alloy and is therefore relatively soft (hence another name for it is "soft tooling"). We still use it today, both for molds and stamping dies, in situations where you need a tool made very quickly or for temporary tooling (for short runs or to bridge the gap until permanent tooling is ready). K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#8

|

|||

|

|||

|

When i worked at Kennametal we did make tools ands dies from carbide that made parts for the auto makers,also we made parts for the govt.We would draw up the dies from supplied designs.The drawings usually were about 4/5 pages.You were using trig all the time to figure the angles.then the dies and rams were made.then we got them back from the die shop.Then we set them up as they were to be used then made a plastic part just like the part to be made.then this part was taked to the die shop where it was placed on the comparator with our drawing next to it.Our drawings had to be accurate.We used pencils that were sharp all the time.If there was a problem,usually polishing the die case was the answer.i remember those guys polishing and polishing those cases.Now everything is cad drawn and calculated.

|

|

#9

|

||||

|

||||

|

Quote:

Depending on........ We would either load the 16 mm film into cartridges or spools to be read by 16 mm film readers or the film originals were loaded into sleeves and microfiches were duped from the stacked film.. We had fiche readers all over the building too. There were some reader printers here an there but many of them used silver based paper and the prints were outrageously expensive. (50 cents to a dollar a print) And, the paper had a very short life span so we might discard thousands of dollars worth of expired paper each year in order to keep some fresh paper on hand. KTF CD175 |

|

#10

|

||||

|

||||

|

While it fun to talk about the technology used in designing and building cars, I remembered with embarrassment this morning the major damage American industry did to itself by allowing foreign visitors to tour our plants and engineering facilities with their cameras.

There was a period that tours of Japanese engineers came through all the time and took pictures of everything. Years later, American engineers made tours of the Japanese plants and observed many of their inventions, innovations and advanced processes in use at Toyota and Honda. And of course, the Japanese patent system works for the infringer better than for the inventor. Have we halted the bleeding yet? KTF citydesk175 |

|

#11

|

|||

|

|||

|

Quote:

No and we won't until the bottom comes completely out of this economy forcing everyone out of work world wide. The japs always were great copycats. Dad told me about the cars they found on Saipan when they first occupied the island. They were twins to the Hudson Terraplanes of the 30's. They [Japs] weren't smart enough, or didn't understand standardized threads at the time yet tho. Dad's crew took one apart to hotrod it and couldn't get it back together because none of the bolts that were the same diameter interchanged with each other! Mike

__________________

so many pontiacs, so little time.................. moderator is a glorified word for an unappreciated prick.................. "Only two things are infinite, the universe and human stupidity, and I'm not sure about the former." --Albert Einstein "There is no such thing as a good tax." "We contend that for a nation to tax itself into prosperity is like a man standing in a bucket and trying to lift himself up by the handle." - Winston Churchill |

|

#12

|

||||

|

||||

|

I am not so sure that the Major Manufacturers do a very good job of using patent protection here in the states either.

I have heard several times that a GM engineer will develop an idea up to the point where it can be built into something solid so it can be tested etc, only to find that the vendor/contractor/job shop has made the drawing, and the part/assembly and beat GM to the Patent Office and now wants to sell their NEW invention to GM at a large premium over the cost of just fabricating the part And people wonder whythis is called a litigious society ktf citydesk175 |

|

#13

|

||||

|

||||

|

Quote:

__________________

John (The Rocket Scientist)  Wishing I was working on my '68 Firebird. Wishing I was working on my '68 Firebird.  Currently on the 20 year resto plan, maybe 25. |

|

#14

|

||||

|

||||

|

Quote:

reverse enginnerring gets you everytime KTF CD175

__________________

There are 2 rules for success in life: 1. Don't tell everything you know 2. ===================== There are 10 types of people in this world" those who know binary and those who don't ======================== |

|

#15

|

||||

|

||||

|

Consider GPS...we could accurately target someone....now they can accurately target US.

George

__________________

"...out to my ol'55, I pulled away slowly, feeling so holy, god knows i was feeling alive"....written by Tom Wait from the Eagles' Live From The Forum |

|

#16

|

||||

|

||||

|

Quote:

Every military base in Vietnam suffered the spectacle of "pacers": Vietnamese who paced off the distances between every large building on the base just to make targeting maps. There is High tech and Lo tech. And the other guy might just find a solution in between. But hell with the other guy for now I am about to go out to my brand new G6 and enjoy it all the way home (I find it hard to get into but it drives very well) KTF CD175

__________________

There are 2 rules for success in life: 1. Don't tell everything you know 2. ===================== There are 10 types of people in this world" those who know binary and those who don't ======================== |

|

#17

|

||||

|

||||

|

Quote:

I ran the "Fender Set" area at the Chevrolet Truck plant for a couple years. I suspect the process between the two products was similar enough that my description would still be accurate in this case: I think you all would be surprised at how the assembly process varies from how you or I would build these cars in our garage. For example, that fender would be completely built up at a remote location in the plant. When conveyed to the final line it would be painted, emblems installed, any rocker trim (if required) already installed, hinges, rubber plugs, fender inner and any baffles already in place. Similarly, the radiator support would have been conveyed to the final line with some subassembly already done. The radiator and AC condenser (if required) as well as any fan shrouds would already be installed. The grille header and bezels were also already installed and the rad support would be swung over onto the chassis, left loose on its mounts and flopped backwards against the fan/shroud until supported. The rad hoses were likely installed shortly after this point but definitely prior to the fenders going on. The two burly young men you see here would grab the fender off the conveyer (one at the front, one at the rear) and swing it, in one fluid poetic motion, over the front tire and into place on the car. There would be a small magnetic spacer placed on the door; the man at the rear of the fender would pull it up tight against that spacer to set the fender/door clearance and drive the vertical bolt at the rear of the fender. Meanwhile, the man at the front would jiggle the fender over the rad support and begin driving several fender nose bolts into the rad support. We also a big stick (like a 2x4) and the rear man would pry against the back of the tire, moving the lower portion of the fender rearward while the man in "the pit" drove the lower anchor bolt. (This big stick could also be used to fit the bottom of the fender in/out, by placing it the door jamb and giving it a good kick!  ). ).This whole front end assembly would be left loose so that it could be slid from side to side to facilitate the hood fit (in relation to the front fenders) at a later station.

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#18

|

||||

|

||||

|

Fitting the front end sheet metal was an "art" in and of itself.

Some of you who have disassembled these cars may have noticed little "shim packs" taped together at various fender attaching points. These were not fitted to individual cars but built up in batches. You would tape shims together to form these little sets, enough to run maybe half the day. Then you would blindly assemble these to the vehicle (ie, not actually paying any attention to how they fit). Usually the cycle would go like this: the supervisor at the end of the line (or the General Supervisor) would call, and in some kind of flowery language say: "!@#$%$^^%^&*^&*!! FIT THE !@#$@%$% FENDERS TO THE CAR!!" At that point you would go back, look at the vehicle currently in front of you and make an assessment of which shims to add/remove. You would make the change on the next vehicle, noting the build number of the car you started with (the "breakpoint") and continue building until the next phone call. The fitters at the end of the line would work their magic with rubber hammers and the aforementioned big sticks. Very rarely would they actually put a wrench on a vehicle and add or remove shims to fit the front end.

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 Last edited by Keith Seymore; 10-29-2008 at 10:06 AM. |

|

#19

|

||||

|

||||

|

Oh - and how is it done today?

Pretty much the same way....  K

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

|

#20

|

||||

|

||||

|

Quote:

or at least able to work together! or at least able to work together! If they couldn't get along, or were feeling ornery, they could bring the line to a screeching halt. On the other hand, if they were in a good mood, one guy could perform both jobs for a period of time while the other used the restroom or visited his girlfriend from the trim shop (all the cute girls worked in the Trim area  ) )

__________________

'63 LeMans Convertible '63 Grand Prix '65 GTO - original, unrestored, Dad was original owner, 5000 original mile Royal Pontiac factory racer '74 Chevelle - original owner, 9.85 @ 136 mph besthttp://www.superchevy.com/features/s...hevy-chevelle/ My Pontiac Story: http://forums.maxperformanceinc.com/...d.php?t=560524 "Intro from an old Assembly Plant Guy":http://67-72chevytrucks.com/vboard/s...d.php?t=342926 |

| Reply |

|

|