| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#1

|

|||

|

|||

|

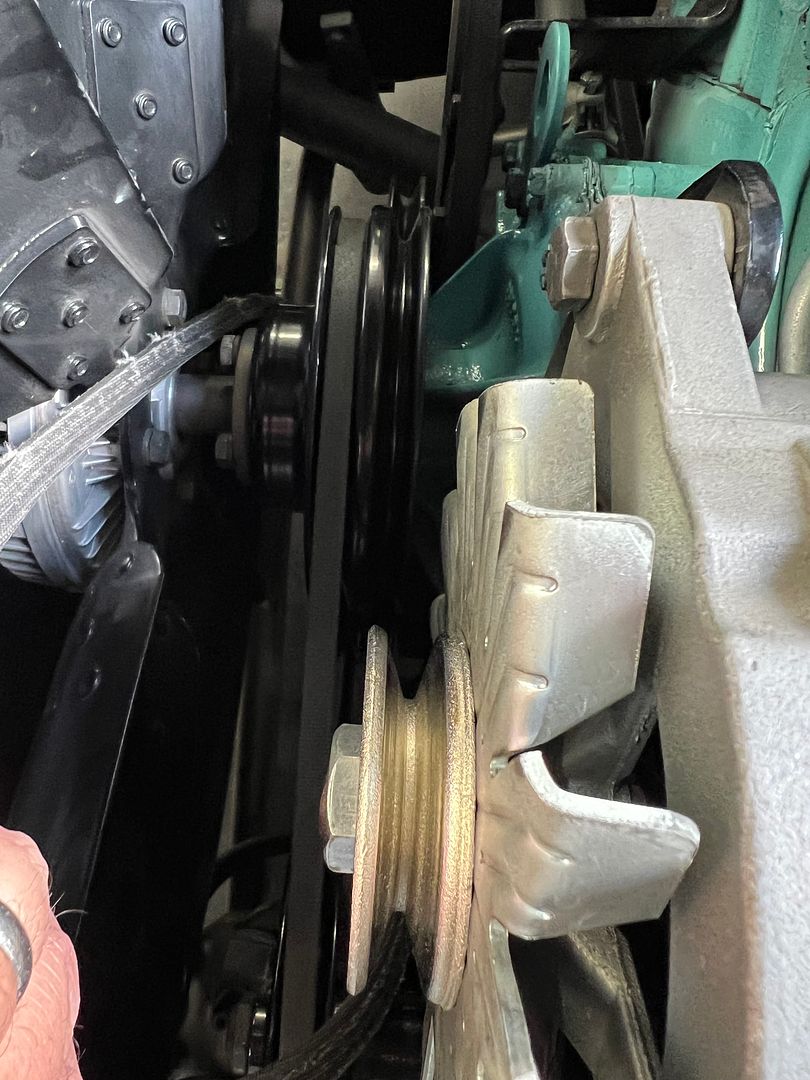

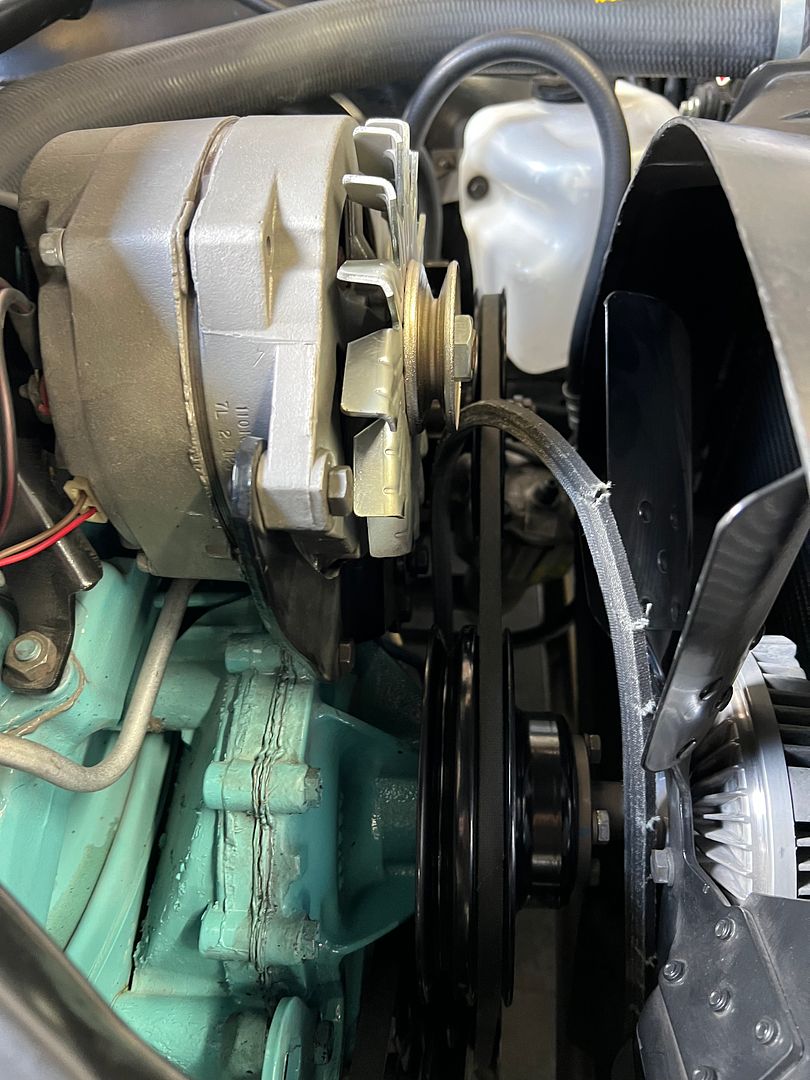

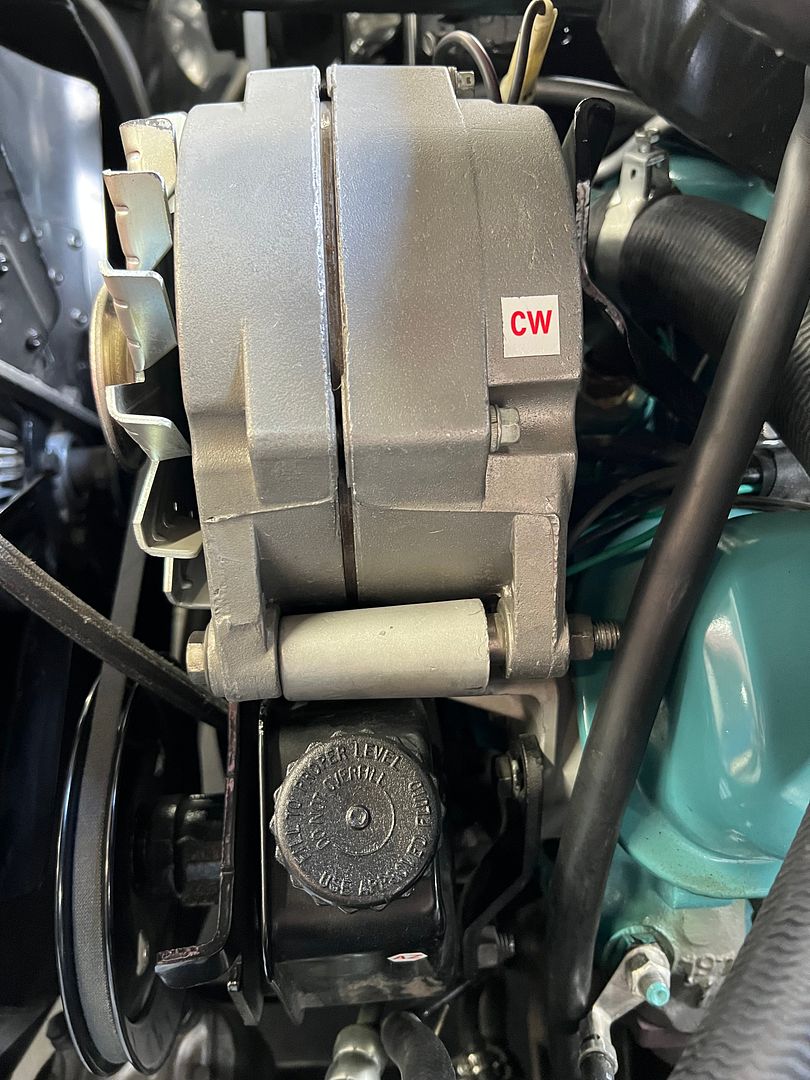

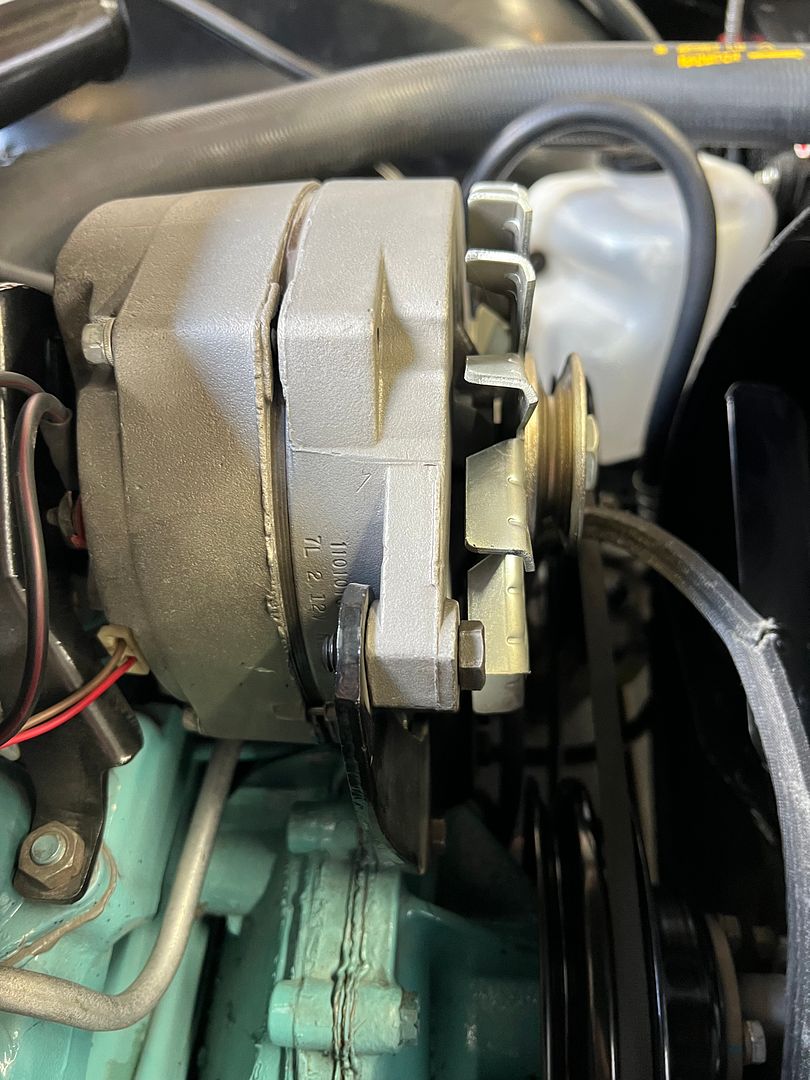

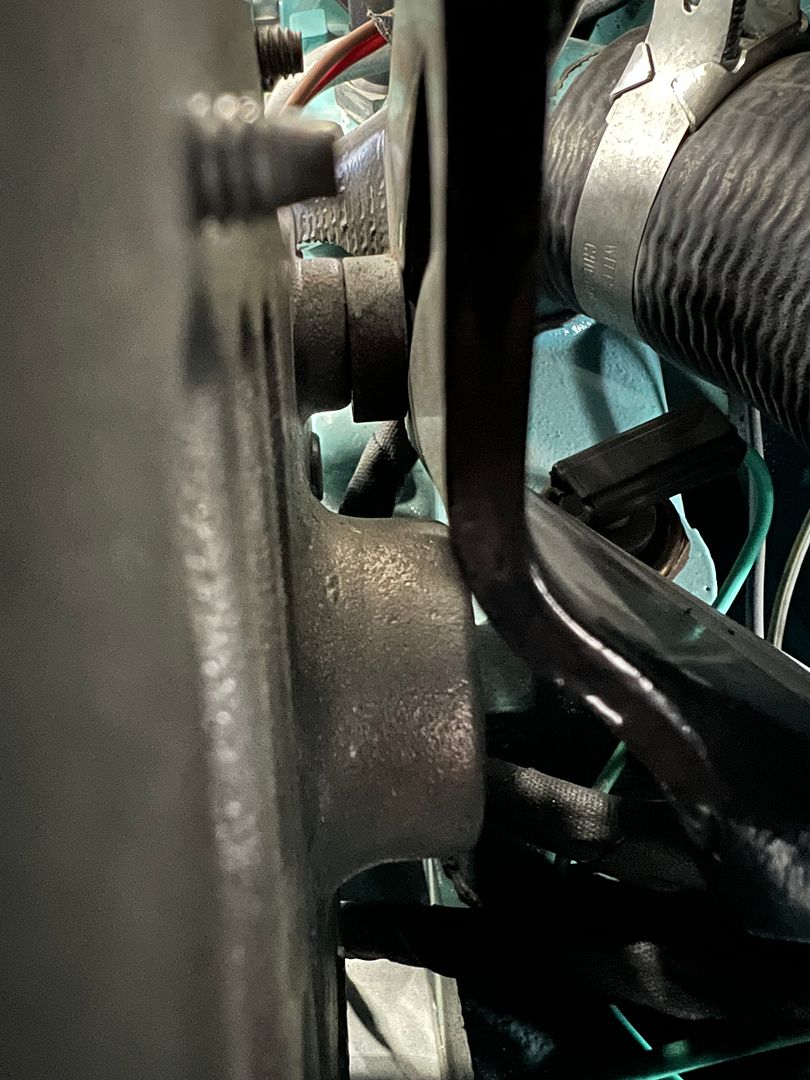

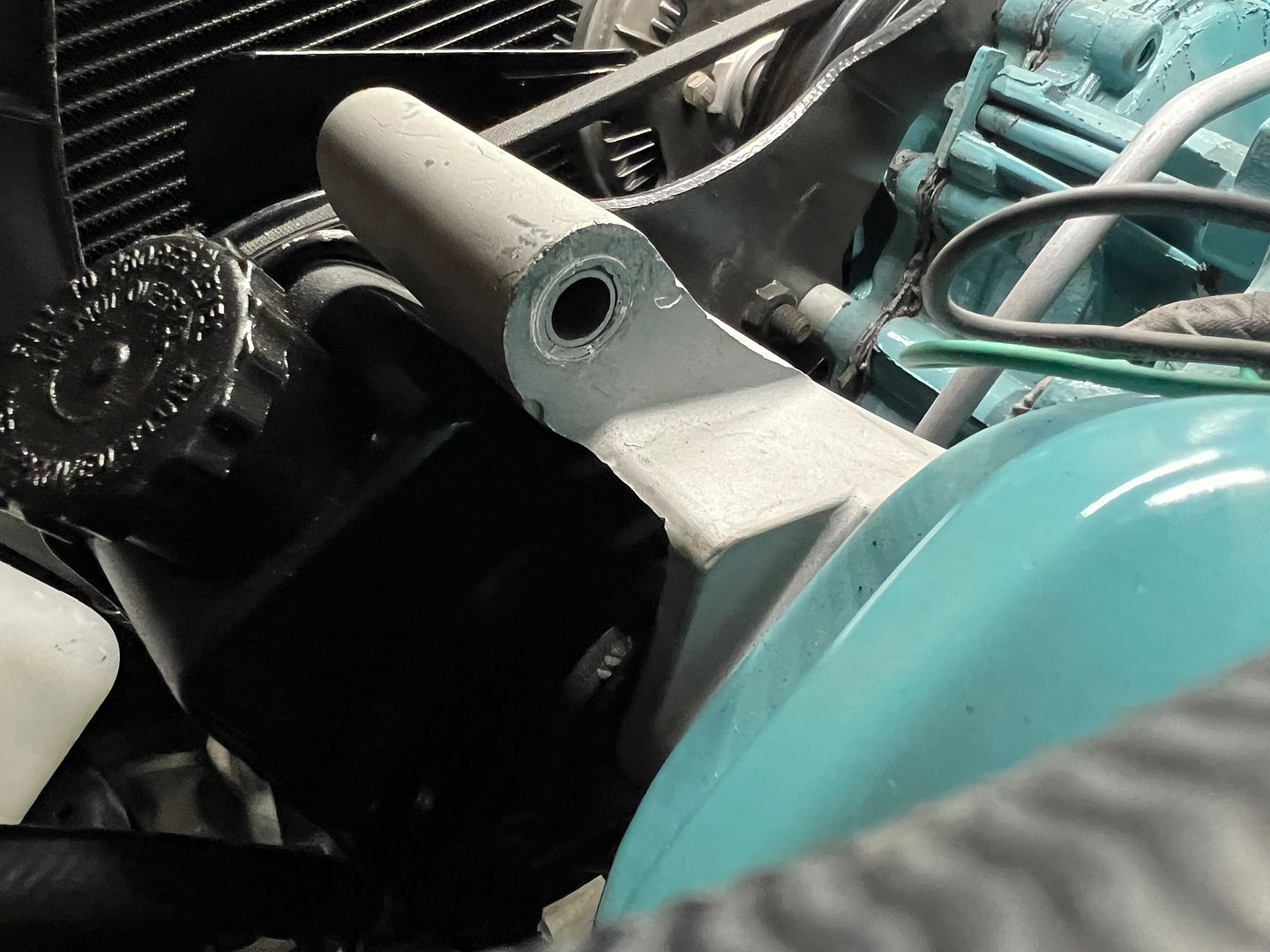

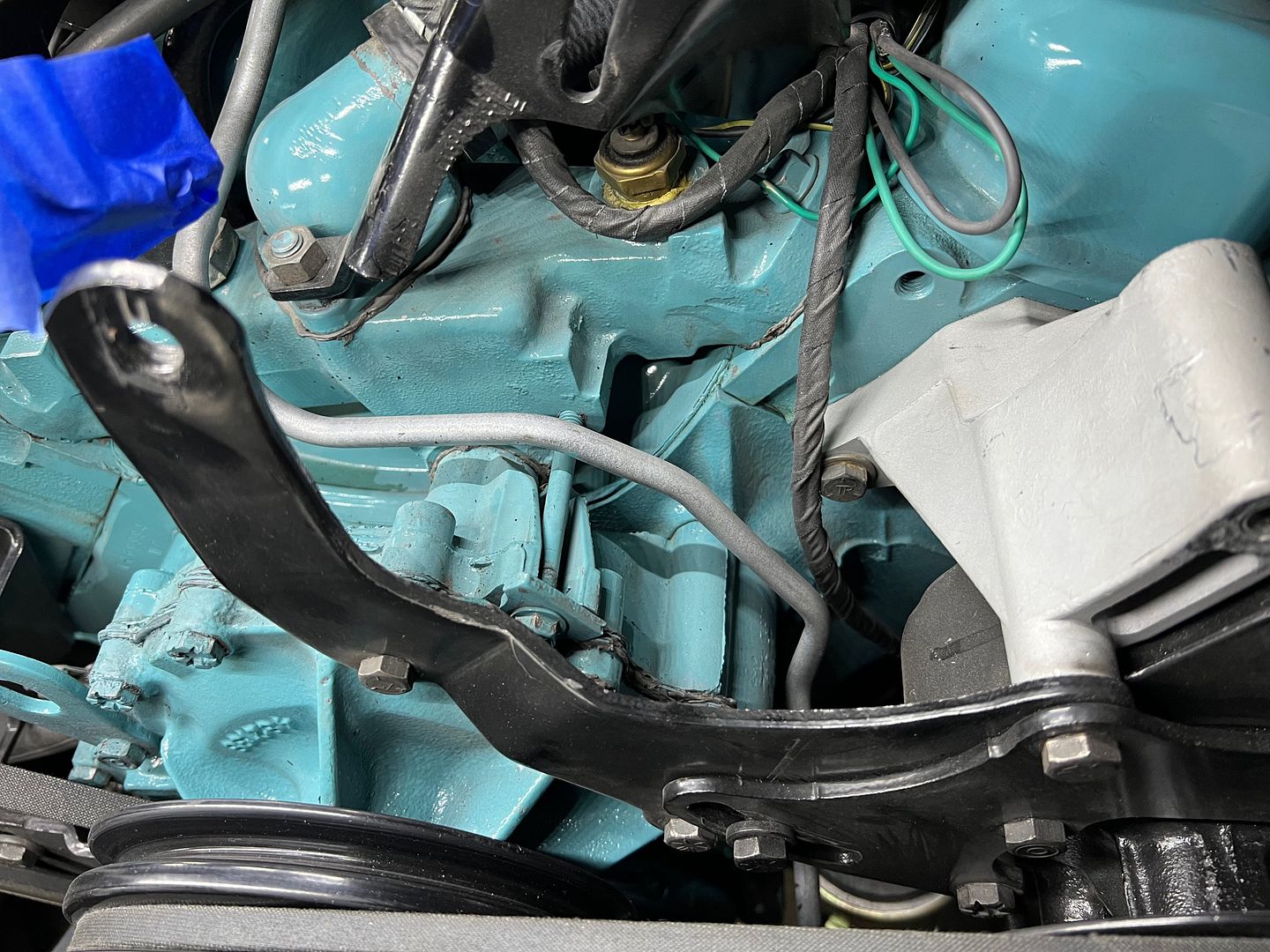

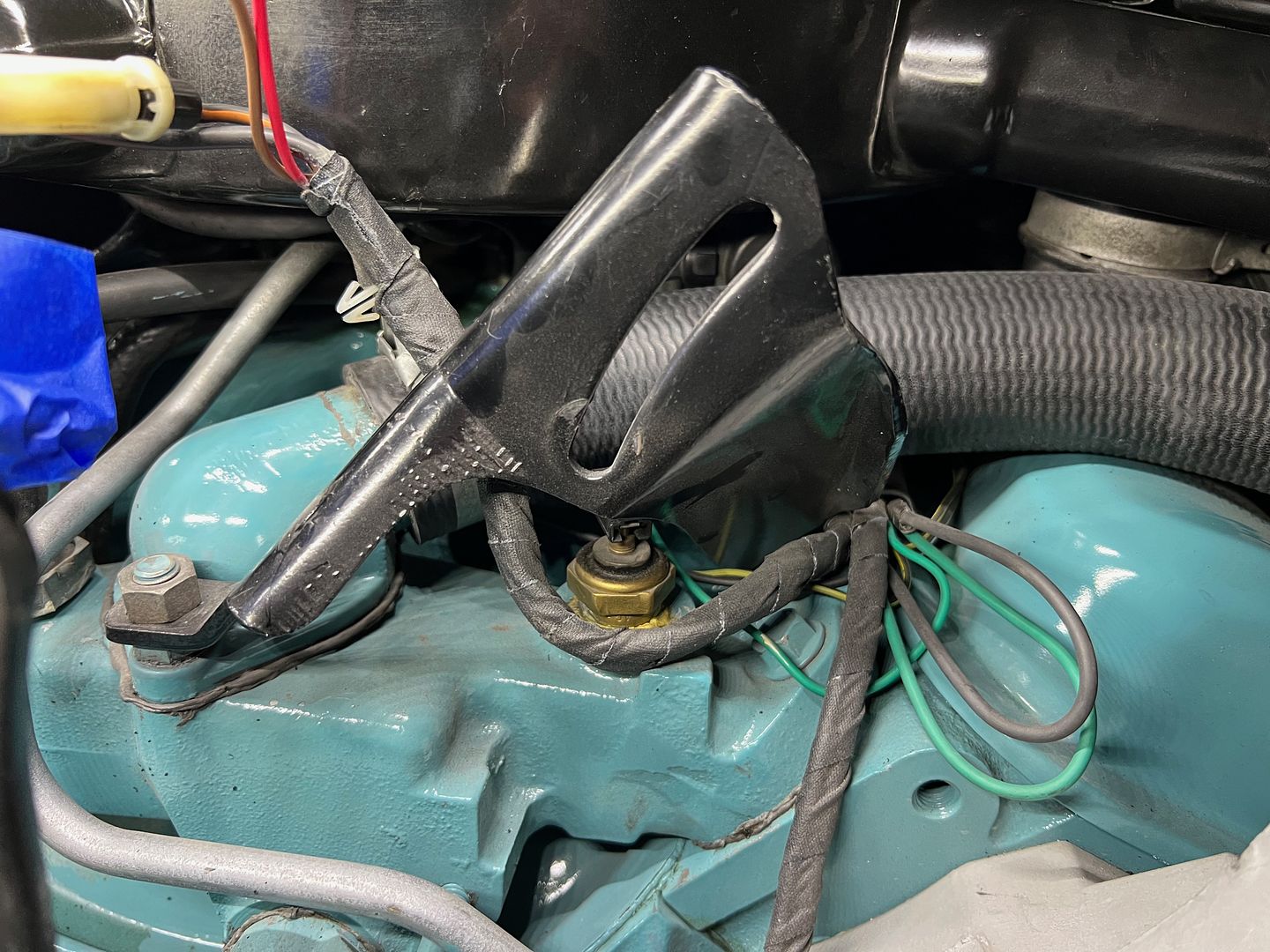

1971 T/A 80 Amp Alt pulley is not aligned with main pulley and it keeps throwing the Alt. belt.

The Alt. pulley needs to come forward (toward radiator) a bit in order to align with the main pulley. Can you please look at the pics and let me know why they are not aligned and how to fix the issue. What parts are incorrect or not installed correctly. The goal is to be factory stock with all equipment. Thank you in advance!

|

|

#2

|

||||

|

||||

Sent from my iPhone using Tapatalk |

|

#3

|

|||

|

|||

|

Brad, it appears something's going on at the swivel area, like the casting where the long bolt goes through is too short. I'll look at my '72's cast bracket later this evening, believe that area is supposed to be tighter.

__________________

Buzzards gotta eat... same as worms. |

|

#4

|

||||

|

||||

|

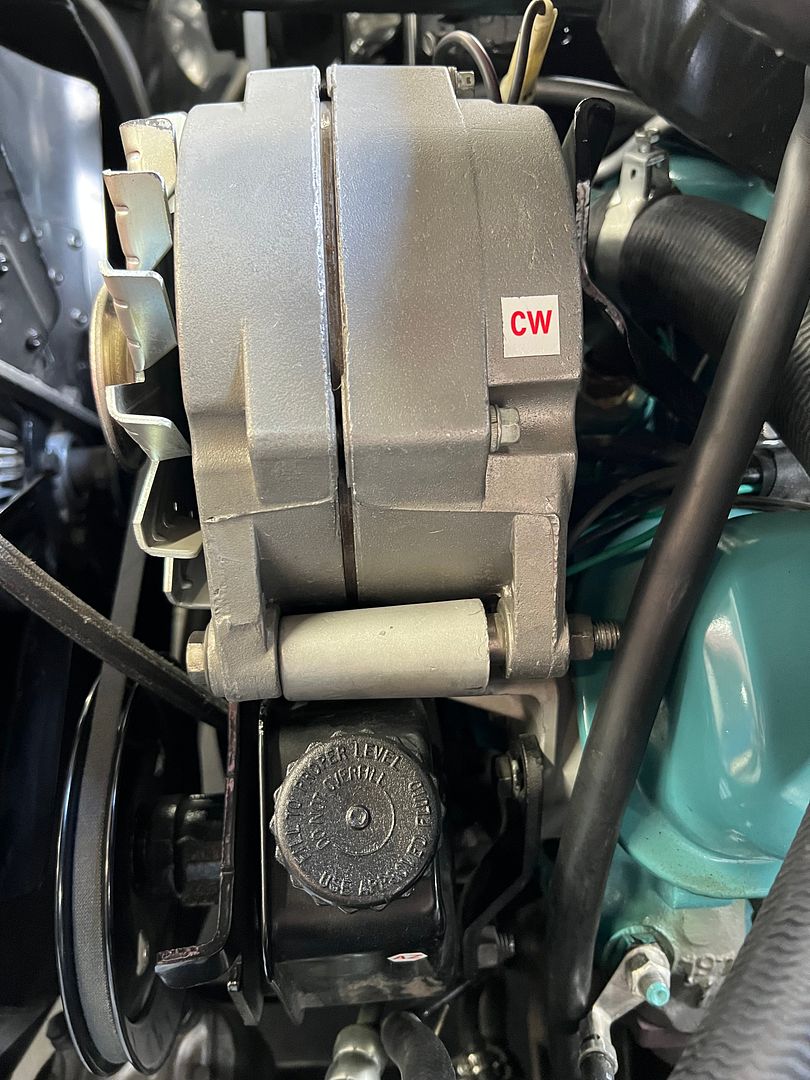

Happen to have the alternator off the car.

Sent from my iPhone using Tapatalk |

| The Following User Says Thank You to DavesGTO For This Useful Post: | ||

|

#5

|

|||

|

|||

|

Brad, G'mornin. Measured the original alt bracket casting on my '72's engine.

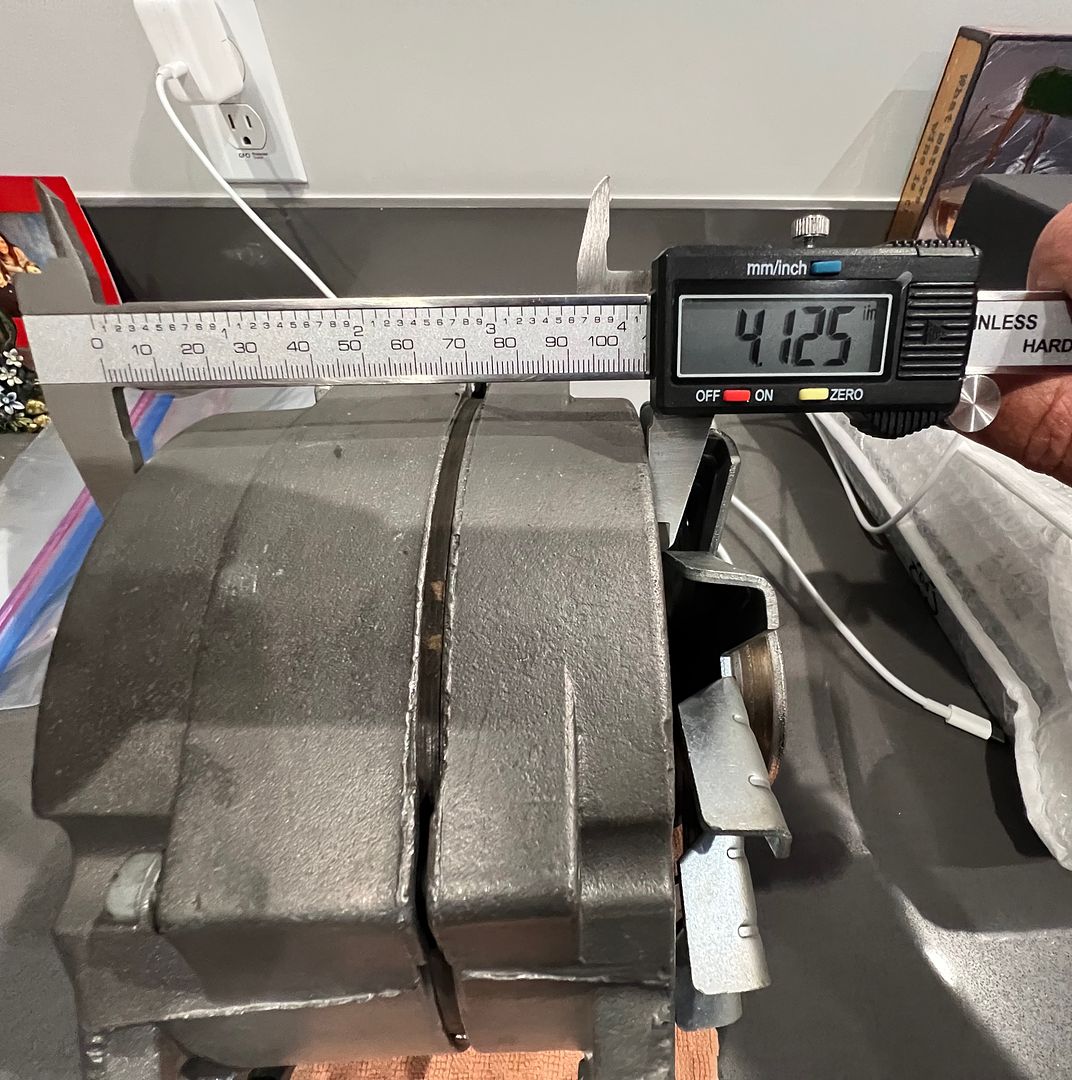

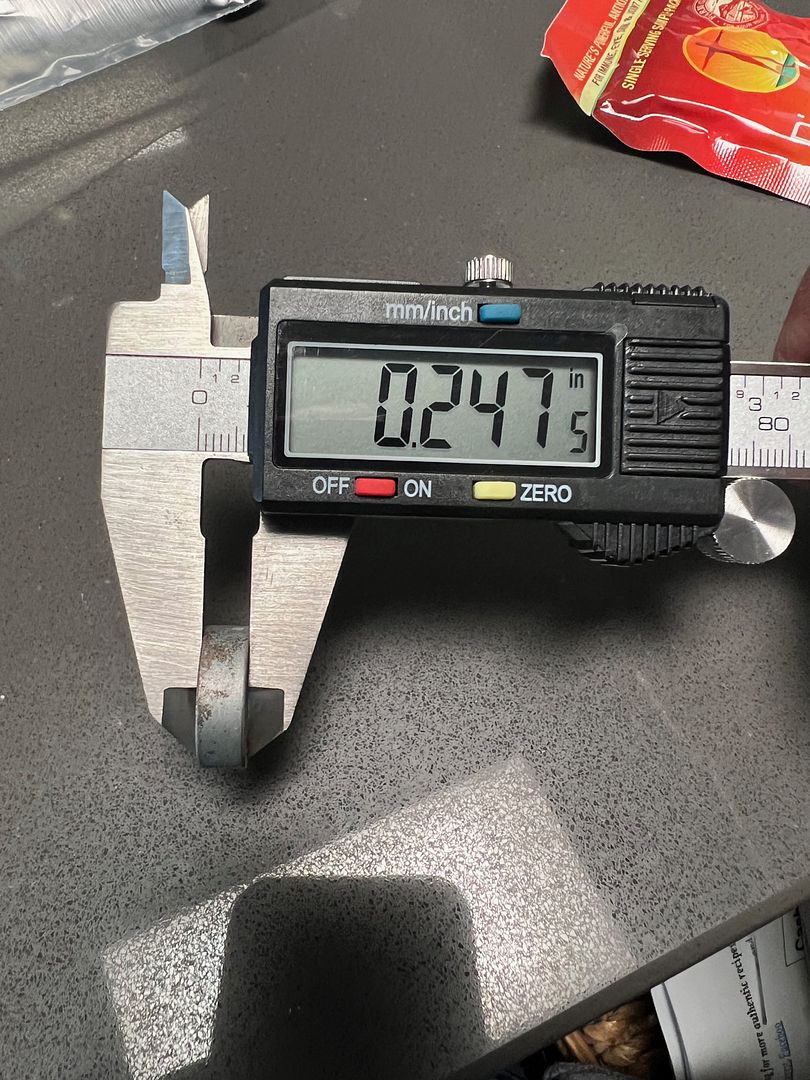

Between the "legs" of the casting 2.49" & change. Original alt is restored, up in the mezz, boxed up, i can pull it out if need be. In the racking, have quite a few of the 80 amp alt brackets, the distance inside between the two "legs" of these cast brackets, varies from 2.47- 2.58" Alt cores, easy to get to, have a hd tray with six late 1015's & 1016's in it. Have more as well (though no more early 1015's). Measuring between the front of the casting, & where steel bushing stops, the measurement varies from 2.46" to 2.59" Just by going from your pics, & the obvious, the steel bushing needs to be further out, to push the alternator further fwd. In pulling original 80 amp alts, I can remember many of them being wedged between the legs of the alt bracket. Roger

__________________

Buzzards gotta eat... same as worms. |

|

#6

|

||||

|

||||

|

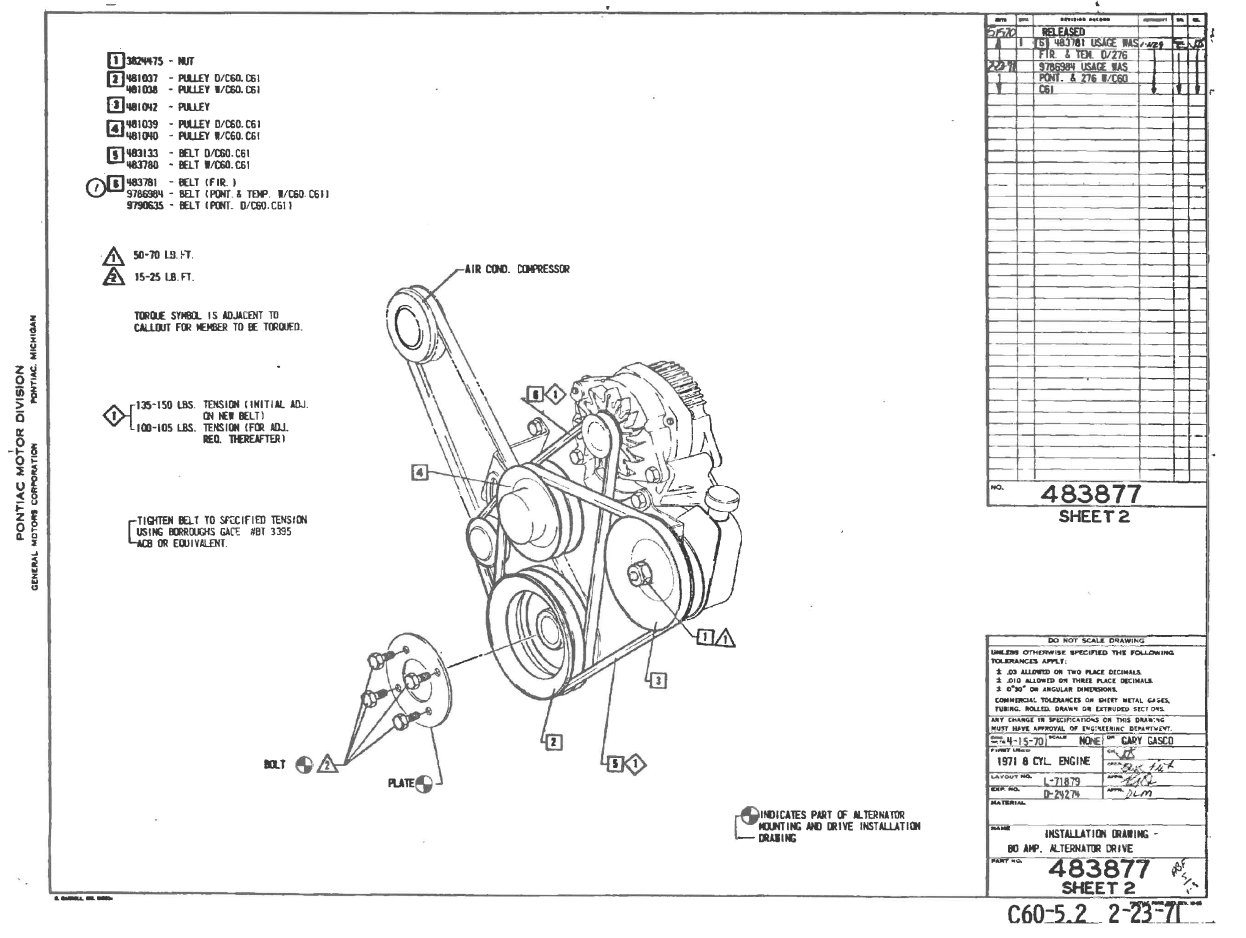

IIRC the bracket set up for a Firebird for the 80 amp has NO adjustment as in its FIXED in place. The adjustment is taken up by the Idler assembly on the lower pass side. Pic@ NJsteve.

Note his PS pump is sitting way to right and has plenty of adjustment on its special bracket to get it near upright. the PS brackets for the 80 am set up are different As I recall ( not 100% on this)

__________________

"The Future Belongs to those who are STILL Willing to get their Hands Dirty" .. my Grandfather Last edited by Formulabruce; 03-06-2023 at 04:00 AM. |

|

#7

|

||||

|

||||

|

The REAR bracket on this is also wrong. The correct one is a mirror image of the more common 55 amp rear bracket. the alternator is crooked in part due to this.

__________________

"The Future Belongs to those who are STILL Willing to get their Hands Dirty" .. my Grandfather |

|

#8

|

||||

|

||||

|

Some more pics since Im awake for a bit..

__________________

"The Future Belongs to those who are STILL Willing to get their Hands Dirty" .. my Grandfather |

|

#9

|

||||

|

||||

|

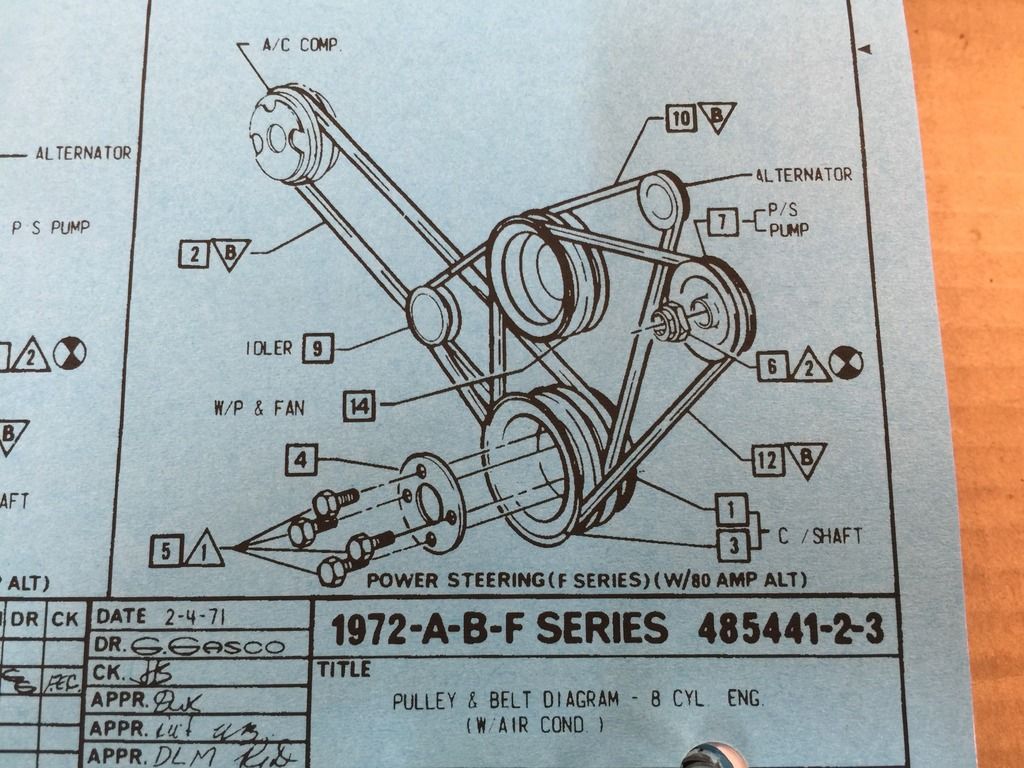

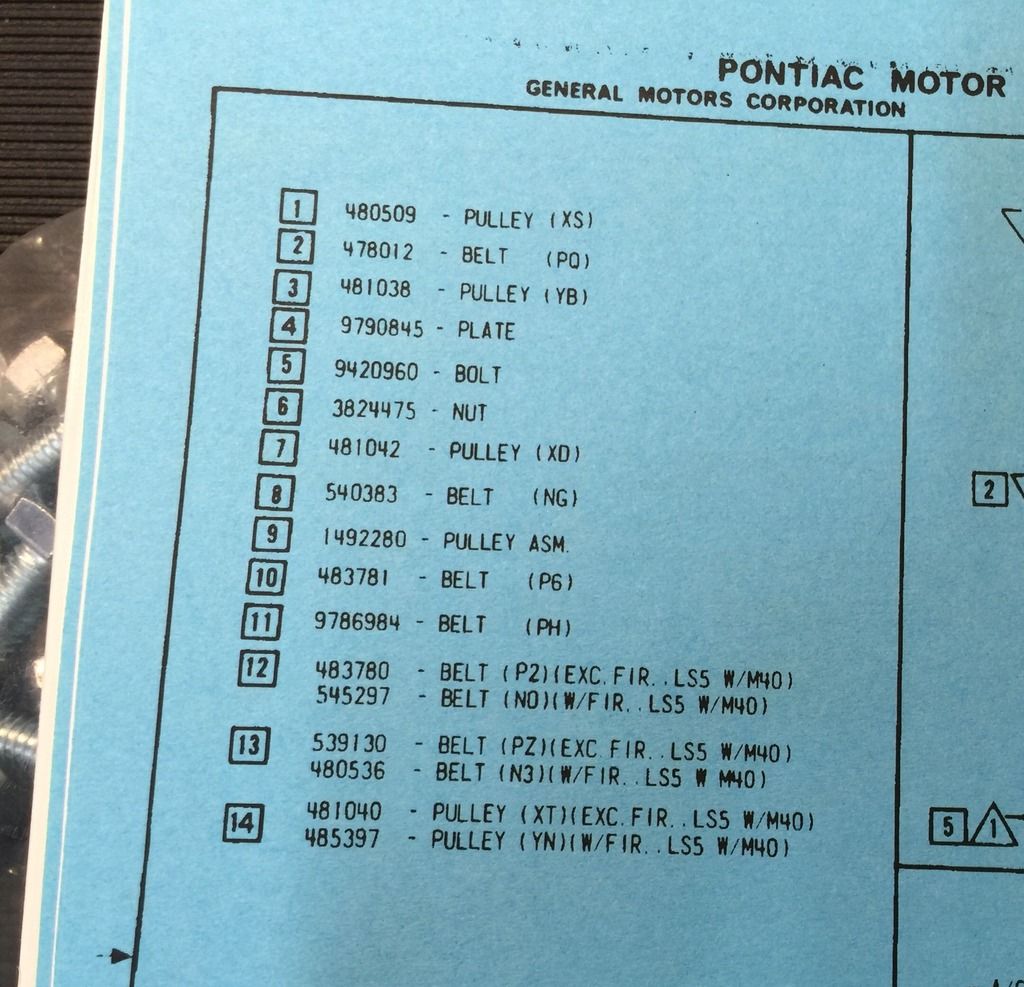

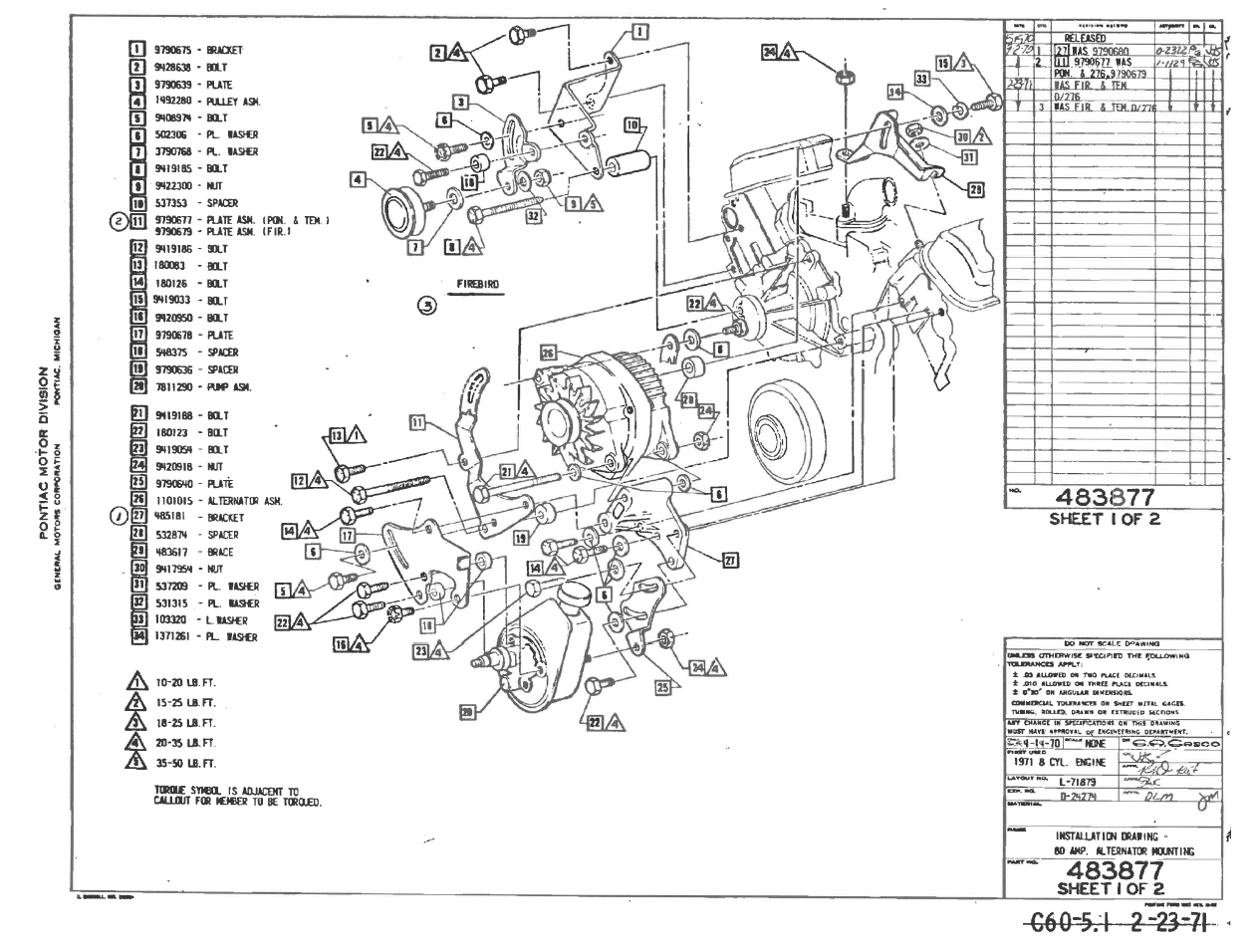

Also check out post #9 HERE for more installed pics ( ALSO the Parts diagram #30 is WRONG Image and shouldn't have that adjuster slot for a Firebird. )

https://forums.maxperformanceinc.com...pulley+bearing

__________________

"The Future Belongs to those who are STILL Willing to get their Hands Dirty" .. my Grandfather |

|

#10

|

||||

|

||||

|

There was a fix for A-body cars (because the hood is taller and won't hit the bracket) that involved throwing away the idler pulley setup and adding an adjustable bracket to the alternator. I did that with my '75. But I had to cut 1-1/2 inches off the slotted section of the bracket (and welding it back together) so it wouldn't hit the underhood bracing.

|

| The Following User Says Thank You to njsteve For This Useful Post: | ||

|

#11

|

||||

|

||||

|

Photo of the A-body bracket next to the F-Body 80 Amp bracket.

Photo of the F-body bracket on top of the modifed A-body bracket. Where it hits the hood if you dont trim it down. Installed setup. It uses the same length belt as the power steering belt. An added bonus is that it gets rid of most of the squeeling belt syndrome the 80 amp idler pulley-equipped cars have. Last edited by njsteve; 03-06-2023 at 04:53 PM. |

| The Following User Says Thank You to njsteve For This Useful Post: | ||

|

#12

|

||||

|

||||

|

I thought the '71 Firebird did not use the idler set up? Just GTO

Quote:

__________________

"Spend all your time and money on that Pontiac GTO pile" - The Go-Gos, 1981 |

|

#13

|

||||

|

||||

|

My photos are from my Gramma's 75 Firebird. 455 swapped 350 Esprit.

|

|

#14

|

|||

|

|||

|

Thank you all for the feedback and research. I need to review what I have installed and then I will post better pics of all the brackets, spacers, etc., attached to the alternator. In the meantime, here are the relevant sheets from the 1971 Assembly Manual.

|

|

#15

|

||||

|

||||

|

Before I purchased that car from Brian Holman he found all of the correct brackets and installed them all as part of his refurb. I never had a belt fall off so if you still have all of the same components it should work fine. 1971 did use the idler pulley in the Firebird models with the 80 AMP alternator.

|

| The Following User Says Thank You to TA455HO For This Useful Post: | ||

|

#16

|

|||

|

|||

|

I pulled the ALT off the car and took some measurements. The pic showing the measurement of 2.488" is for the bracket that fits in-between the ALT's ears. Can anyone see a reason why the pulley is not lined up correctly?

Last edited by hiyabradHO; 06-22-2023 at 09:24 PM. |

|

#17

|

|||

|

|||

|

A slim possibility would be the holes for the pivot mounting are the wrong size. I noticed the alt is a rebuilt unit. The numbers on your pulley end case half are correct for the smaller 3/8 bolt . It may have been drilled out to accommadate the later 80 and 100 amp alts that used a 10mm bolt. The rear case has an adjustable spacer that was 3/8 for the early style and the later style were 10mm. A 3/8 bolt in a 10mm hole will be sloppy and can cause the alt to be cocked. Put the caliper in both holes of the pivot mount of the alternator and take a measurement. If you can't measure it put the bolt through the pivot holes of the alt to see if there is excessive play around the bolt. There should be very little play.

|

|

#18

|

||||

|

||||

|

Assembly manual for '71 lists diagram #27 bracket as 485181. 1972-4 uses 485991 bracket.

Both use the 1101015 alternator. 1975-up used the 1101016 alternator with the 486663 bracket. Maybe it's as simple as that, matching the 2.

__________________

So long, farewell. |

| The Following User Says Thank You to Held for Ransom For This Useful Post: | ||

|

#19

|

|||

|

|||

|

Quote:

It looks like my car has 1101016 on it which would be the later model ALT and not for my '71. Do you concur? |

|

#20

|

|||

|

|||

|

The aluminum pivot block ("bracket") has a raised casting number.

There is a difference in the shape on the far driver side of the casting. Dont believe it effects the pisitioning of the alternator I'll pull a few out & get a few pics.

__________________

Buzzards gotta eat... same as worms. |

| Reply |

|

|