| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

#21

|

|||

|

|||

|

Don from Mezziere told me to run the stat

i run the high flow 160 stat i know it has a small air bleed, but i dont remember if it has drilled holes too some reason i think it does as i see a little circulation at cool temps in the rad have had this setup 10+ years no problem it's the 42gph pump i'd like to swap to the 55gph just to help a little more when its 100+ outside i run dual e-fans on at 185 off at 165 |

|

#22

|

||||

|

||||

|

Hmm: Good to know, Thanks for posting info. I run same setup with the fans with a manual by pass switch. Works really nice.

__________________

68 Firebird. IA2 block, 505 cu in, E-head, Solid roller 3650 weight. Reid TH400 4:11 gear. 29" slick. Best so far 10.12@133 mph. 1.43 60 ft. 76 Trans am, TKX .81 o/d, 3.73 Moser rearend, 468 with KRE D-ports, Doug headers, 3" Exh. |

|

#23

|

|||

|

|||

|

If you search on the internet regarding this subject you will find where many have stated Meziere has told them NOT to run a thermostat, as in my situation. Then there are others who have stated they were told to run a thermostat by Meziere. Or restrictor.

Can we not presume it can be application specific and determined during a conversation with a Meziere rep. And remember the GPM ratings are a free flow rating. It is supposed to be a “free flow” number with zero back pressure and zero inlet pressure. But there caveats. https://bangshift.com/general-news/t...inside-engine/ .

__________________

'70 TA / 505 cid / same engine but revised ( previous best 10.63 at 127.05 ) Old information here: http://www.hotrod.com/articles/0712p...tiac-trans-am/ Sponsor of the world's fastest Pontiac powered Ford Fairmont (engine) 5.14 at 140 mph (1/8 mile) , true 10.5 tire, stock type suspension https://www.youtube.com/watch?v=qDoJnIP3HgE |

|

#24

|

||||

|

||||

|

Quote:

__________________

|

| The Following User Says Thank You to Hammertime Mike For This Useful Post: | ||

|

#25

|

||||

|

||||

|

Quote:

Ya, it's all good Steve. Good to get people with actual testing done. At this point I'm going to try a few things see how they work out. Can't wait till season opens up again. Thanks for info. and link.

__________________

68 Firebird. IA2 block, 505 cu in, E-head, Solid roller 3650 weight. Reid TH400 4:11 gear. 29" slick. Best so far 10.12@133 mph. 1.43 60 ft. 76 Trans am, TKX .81 o/d, 3.73 Moser rearend, 468 with KRE D-ports, Doug headers, 3" Exh. |

|

#26

|

|||

|

|||

|

Stated here, and a good point.... "Temps in the block and temps in the intake crossover will be different with no circulation"

Old Smokey Yunik quote regarding a restrictor... "If it is too large,the water will flow through the system too quickly ,and if it is too small, the water will flow too slowly!" It was my presumption that was within the subject regarding flow thru the radiator, and noting from the 'Dinosaur' age. Suggesting more 'time' in the radiator is better ? With a modern aftermarket radiator design with a great capacity for cooling, does one want to restrict the flow thru the block ? .

__________________

'70 TA / 505 cid / same engine but revised ( previous best 10.63 at 127.05 ) Old information here: http://www.hotrod.com/articles/0712p...tiac-trans-am/ Sponsor of the world's fastest Pontiac powered Ford Fairmont (engine) 5.14 at 140 mph (1/8 mile) , true 10.5 tire, stock type suspension https://www.youtube.com/watch?v=qDoJnIP3HgE |

| The Following User Says Thank You to Steve C. For This Useful Post: | ||

|

#27

|

||||

|

||||

|

Run a DC Control PWM variable speed controller. They make a unit that will control a pump and a fan. Adjust it to control the coolant temp wherever you want it, and your engine will run at a constant temp (instead of spiking up and down) and no need for a t-stat.

__________________

'73 T/A (clone). Low budget stock headed 8.3:1 455, 222/242 116lsa .443/.435 cam. FAST Sportsman EFI, 315rwhp/385rwtq on 87 octane. 13.12 @103.2, 1.91 60'. '67 Firebird [sold], ; 11.27 @ 119.61, 7.167 @ 96.07, with UD 280/280 (108LSA/ 109 ICL)solid cam. [1.537, 7.233 @93.61, 11.46 @ 115.4 w/ old UD 288/296 108 hydraulic cam] Feb '05 HPP, home-ported "16" D-ports, dished pistons (pump gas only), 3.42 gears, 275/60 DR's, 750DP, T2, full exhaust My webpage http://lnlpd.com/home |

| The Following 2 Users Say Thank You to Lee For This Useful Post: | ||

|

#28

|

|||

|

|||

|

Unless there was a misunderstanding on my part. Talk with Jerry at Meziere and he will suggest a PWM variable speed controller on the water pump has no distinct advantage for controlling water temp except for bringing the temp up after starting. Otherwise use a thermostat for that reason, and agrees in doing so it will affect the flow rate.

.

__________________

'70 TA / 505 cid / same engine but revised ( previous best 10.63 at 127.05 ) Old information here: http://www.hotrod.com/articles/0712p...tiac-trans-am/ Sponsor of the world's fastest Pontiac powered Ford Fairmont (engine) 5.14 at 140 mph (1/8 mile) , true 10.5 tire, stock type suspension https://www.youtube.com/watch?v=qDoJnIP3HgE |

|

#29

|

||||

|

||||

|

Seems to me it can vary depending on your setup. My car will have no heater and a blower intake with a Moon front cover. Using a remote pump. Without adding some sort of bypass, if I use a thermostat, 55 GPM will have nowhere to go until it opens. Not sure how big a bypass is necessary to provide adequate flow while the engine warms up. Iím leaning towards no thermostat. Still a ways off before I see how it all works out.

Good thread.

__________________

" Darksiders Rule "

|

| The Following User Says Thank You to misterp266 For This Useful Post: | ||

|

#30

|

||||

|

||||

|

Well, the only way I see water moving through the block when the thermostat is closed, is the bypass from water crossover and the return from the heater core. It the thermostat is drilled with a couple of holes, then water is going to move toward the radiator. For me I want the water moving around the engine block while it warms up. Therefore a bypass is needed. Otherwise the water flow is not moving. The way I see it, water is constantly flowing through the block and when thermostat temperature is reached water starts to flow to rad which mixes with block water to cool engine. This way the thermostat maintains proper engine temperature at all times.

I also am not using the heater core in the car, but I had it setup before with mechanical pump, and I took two lines off the back of the heads and routed them to the front water crossover. I split off on side and went to the return on the water pump. I left the bypass in place. I ran a 160 thermostat and had no heating issues. I have since gone to the electric water pump and that is how this post started for me. I think Misterp266 you got me thinking again on the way I have it setup now. I hate the thoughts of not running the thermostat. I'm going to setup my hoses like before and install my 160 thermostat and run the electric water pump and see how it goes. What I'm trying to duplicate is the way the Engineers set it up in the first place. Water in block is constantly circulating and when thermostat opens it regulates engine temp. I like it when engine stays at a proper temp. I'm starting to believe with no thermostat the engine temp will be bouncing around and not be constant. Now, it's 2 am here and couldn't sleep. So I started putting some thoughts down. Misterp266, you got me thinking... Thank you to all that have posted.

__________________

68 Firebird. IA2 block, 505 cu in, E-head, Solid roller 3650 weight. Reid TH400 4:11 gear. 29" slick. Best so far 10.12@133 mph. 1.43 60 ft. 76 Trans am, TKX .81 o/d, 3.73 Moser rearend, 468 with KRE D-ports, Doug headers, 3" Exh. |

|

#31

|

||||

|

||||

|

Quote:

The Moon Cover, as you know, has two "flat ears" that seal to the block surface. I use a Meziere 55 gallon/Hr radiator mounted electric water pump that has two water outlets on the pump. I plumb one water pump nipple to the Passenger side ear on the Moon Cover. I plumb the second water pump nipple to the Drivers side ear on the Moon Cover. That Drivers side ear has a "Y" before the ear. The lower leg of the "Y" gets water from the second nipple on the Electric Water Pump. The upper leg of the "Y" gets water from the water passage that would normally mate to the factory timing cover with a "O" ring seal. I run a thermostat with two 1/8" holes drilled into the stat to bleed TRAPPED AIR that may be in the cross-over. The thermostat works like normal. Before the engine warms up the "By-Pass Leg on the drivers side does exactly the same job as stock but with a slightly different plumbing. Same for after the Thermostat opens. I run a 180 stat as I live in Michigan. I love the Moon Part and the Meziere Pump. I did not come up with this By-pass design. A friend years ago showed the Mod to me. Non Pontiac guys think it is stock, LOL! And it clears a Cog Belt driven supercharger belt. I don't run cog belt Vortech Superchargers. Hope this helps. Tom V.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

| The Following User Says Thank You to Tom Vaught For This Useful Post: | ||

|

#32

|

||||

|

||||

|

I just contacted him with some questions (and to buy) and he said they are sold out and to check back in a month or so to see if that has changed.

__________________

James 1970 Trans Am Spotts Built 484" IA2, Highports, EFI Northwind Terminator X sequential EFI fabrication and suspension by https://www.funkhouserracecars.com/ |

|

#33

|

|||

|

|||

|

Tom

do you have photos of the radiator mounted pump? did you have to do something special to mount to the radiator? I didn't know they had one like that i've seen them mounted on engine plates (which i dont have) i've been wondering how i can mount one up in my 79 firebird I want the higher flow capability over what i have now |

|

#34

|

||||

|

||||

|

Tom V.

I have the single outlet version but will split that and run to two fittings on the Moon cover. With the blower intake there is no bypass. I want to run a hose from the crossover down to the inlet side of the pump so water gets circulated by the pump. Also add holes in the thermostat. The way you describe your bypass, it sounds like the pump would not be circulating water. Doesn’t a stock bypass connect to the inlet side of the stock pump? You are connecting to the outlet side. What size fittings are you using on the Moon cover? I was planning on -12AN. Can you post pics of your setup? Rob

__________________

" Darksiders Rule "

Last edited by misterp266; 01-27-2022 at 03:55 PM. |

|

#35

|

||||

|

||||

|

Here is an update on my coolant setup. I went back to the way I had it setup last summer and it worked really nice with the mechanical pump.

I ran a coolant hose from the back of the driver head to the crossover. I also ran a coolant hose from the passenger head to the crossover and also went to the return on the water pump. Bypassed my heater core. I had my son weld 2 fittings in the crossover. I also drilled 2-1/8” holes in my 160 *thermostat which help remove any air trapped in the heads/block. I fired the engine yesterday and it ran really nice. The engine came up to 160 * and the thermostat opened and temp stayed fine. The electric water pump worked great. The electric fans cooled the engine no problem. The way I have it setup is the water circulates through the bypass and also through the heater core return on the water pump. So water is always circulating in the block and heads. Thermostat opens and water is circulated through the rad. I have it also setup that the electric water pump starts when the engine is started. I also have it on a manual switch to turn on with engine off. I have the electric fans set up on a sensor that turns them on at 185* and off at 165*. I also have the fans on a manual switch. The reason I went back to the thermostat setup is I didn’t like the way the water in the rad was working. I installed a 2” adapter on my water crossover and that was when things started working weird. I filled the rad up removed most of the air in the system and when I would start the electric pump the water would drop like 7 inches in the radiator. I finally figured out what was causing that, which was the 2 inch adapter I installed on the crossover. I remove that adapter and everything in the rad came back to normal. I installed my crossover with the two fittings welded in it. (As in Pic) It had to do with the level of the radiator and the level of the water in the engine crossover being at different heights. This is a pic of my crossover for the water feed from back of the heads. The other pic is the adapter I tried on the water crossover. Having the fittings in the water crossover keeps the water level in the block and in the radiator at the level it was design for. So the radiator water lever never fluctuates when the water pump is turned on. I also believe now that the bypass and heater core return remain operational as it is essential if running an electric water pump, that way you never are dead heading the pump and also the water pump has a decent supply of water when the thermostat is closed. If there is no thermostat, then that’s a different deal. I also believe a couple 1/8 bypass holes in the thermostat help remove any air in the block/heads if there is or would be cavitation to the pump impeller. I guess what one has to take into consideration with these electric water pump is that they run at a constant speed regardless of engine rpm. I’m starting to think that is the reason that they want the thermostat removed, and then try to match the flow to the radiator with restrictor plates. Once the thermostat opens your essentially the same as if your running a restrictor plate. I like the idea of the thermostat in place as it allows the engine to come up to temp faster and also helps heat the oil up. Thermostat also help regulate the engine temp. Keeps the engine at 160* in my case. Just my .02.

__________________

68 Firebird. IA2 block, 505 cu in, E-head, Solid roller 3650 weight. Reid TH400 4:11 gear. 29" slick. Best so far 10.12@133 mph. 1.43 60 ft. 76 Trans am, TKX .81 o/d, 3.73 Moser rearend, 468 with KRE D-ports, Doug headers, 3" Exh. Last edited by chuckies76ta; 02-02-2022 at 12:18 PM. |

|

#36

|

||||

|

||||

|

https://www.meziere.com/Products/Coo...ut-55-GPM.aspx

Above is the Meziere Radiator-Mount/Electric-Pump-Radiator-Mounted-High-Flow-Dual-out-55-GPM link. Dual outlets go to the Moon Timing cover ears. Tom V. I posted the Factory Timing Cover to show that you can add bypass water from the heads to the heater return nipple on the timing cover. It feeds the inlet side of the normal water pump, or timing cover electric water pump.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

| The Following 2 Users Say Thank You to Tom Vaught For This Useful Post: | ||

|

#37

|

||||

|

||||

|

Quote:

__________________

James 1970 Trans Am Spotts Built 484" IA2, Highports, EFI Northwind Terminator X sequential EFI fabrication and suspension by https://www.funkhouserracecars.com/ |

|

#38

|

||||

|

||||

|

Morning James: Ya I think the water adapter sets the water level like two inches higher. What was happening was as you know water will settle out to it level point on two different objects. So if you put liquid in a clear hose and move both ends up and down the liquid will settle out to the same level in the hose. What I believe was happening was the water in the engine block was filling the coolant lines on the heads to the crossover and the return hose to the radiator and causing the water in the radiator to drop like the 7 ". As I kept filling and the radiator it started to drop less and less. I just didn't like the way it was working every time I turned the water pump on. I figured since there was no thermostat I could fill the rad right up and purge all the air out of the system. When I did this and turned the water pump on the water dropped down in the radiator and when I shut the water pump off the water rose up and overflowed out the radiator.

Anyhow, If you want the adapter, you can borrow it and down the road when there available send me mine back. I might still try do some experimenting with the adapter this summer. If that works for you P/M me and I'll send it to you.

__________________

68 Firebird. IA2 block, 505 cu in, E-head, Solid roller 3650 weight. Reid TH400 4:11 gear. 29" slick. Best so far 10.12@133 mph. 1.43 60 ft. 76 Trans am, TKX .81 o/d, 3.73 Moser rearend, 468 with KRE D-ports, Doug headers, 3" Exh. |

| The Following User Says Thank You to chuckies76ta For This Useful Post: | ||

|

#39

|

||||

|

||||

|

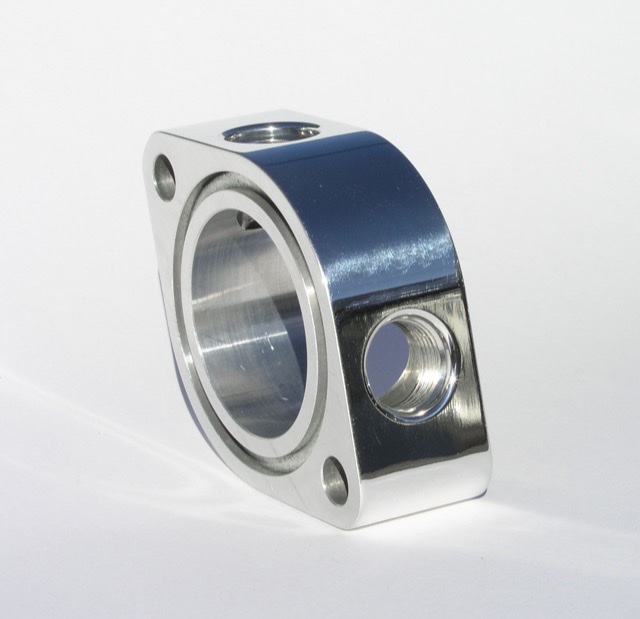

I need a new flex plate so I reached out to Meziere and while looking on the website they apparently make water neck spacers. I talked to Don via email and he’s willing to make one for me if I can give him the correct center-to-center distance on the bolt holes for a Pontiac water neck. Does anyone know off the top of their head or have any of you measured? I know it could be slotted but I’m trying to have it done right. Who knows, maybe after this he’ll start stocking them for Pontiac as well since he’ll have the measurements? Any help is greatly appreciated!

They are only $38 so I may order a few in case anyone else needs one. https://www.meziere.com/Products/Coo...-BB-Mopar.aspx

__________________

James 1970 Trans Am Spotts Built 484" IA2, Highports, EFI Northwind Terminator X sequential EFI fabrication and suspension by https://www.funkhouserracecars.com/ |

|

#40

|

||||

|

||||

|

Quote:

__________________

James 1970 Trans Am Spotts Built 484" IA2, Highports, EFI Northwind Terminator X sequential EFI fabrication and suspension by https://www.funkhouserracecars.com/ |

| Reply |

|

|