| FAQ |

| Members List |

| Social Groups |

| Calendar |

| Search |

| Today's Posts |

|

|

| Pontiac - Boost Turbo, supercharged, Nitrous, EFI & other Power Adders discussed here. |

| Reply |

|

|

Thread Tools | Display Modes |

|

|

| Pontiac - Boost Turbo, supercharged, Nitrous, EFI & other Power Adders discussed here. |

| Reply |

|

|

Thread Tools | Display Modes |

|

#61

|

|||

|

|||

|

For reference, FAST uses Accufab's TB.

|

|

#62

|

|||

|

|||

|

Got side tracked on my EFI install after starting to clean up the car where the gas tank goes. I ended up pulling out the tail lights and harness after finding rust. Tried getting the bumper out but have issue with one stripped nut. I'll work on that next time. Ordered KBS coatings all-in-one chassis kit in gloss black.

Mounted the ECU on top of my glove box so it stays hidden and stock appearing. I'm debating about installing the igntion box under the console behind the shifter because my car doesn't have power windows. Disregard the ECU in front for my mockup. Anyways, hope some of the followers on this thread like the work. I always enjoy seeing a car come together nicely on a forum.

|

|

#63

|

|||

|

|||

|

Find another location. Tunnel will get warm - hot even with heat/ sound dampener. Electronics dont like heat. Also with the console, there is little air flow.

Killing glove box will probably be your best bet or mount it behind the box & above the heat box somehow. |

|

#64

|

|||

|

|||

|

Behind kick panel if you have room

|

|

#65

|

||||

|

||||

|

Floor insulation can avoid potential heat problems mounting it on the trans tunnel in front of the console. The only real thing to worry about there IMO is the heater vents, both one, blocking heat for you, and two, potentially blasting hot air directly at it, conversely in the summer with the vent set to cool it should get some fresh air at that location.

On my '69 Firebird I mounted it in front of the console, you can see the plugs. I drove the car all last summer and most the snow-less winter.  On my Skylark I mounted the ECU to the heater box. This car does not come with a heater control valve so hot coolant flows through the heater box all the time, and it's been there since 2009 without issue. Just trimmed the A/C vent cover and can still use the glove box.   The smaller MegaSquirt 1&2 case didn't require any trimming.

__________________

__________________________________________ "How I learned to stop worrying and love the OHC Pontiac L6"  The Silver Buick- '77 Skylark coupe w/455, SPX, MegaSquirt 3 & TKO-600 (Drag Week 2011, 2012 & 2015!) 1969 Firebird with a turbo'd Pontiac L6 controlled by a MegaSquirt 3 and backed with a microsquirt controlled 4L60e and 4.56 gears! (Drag Week 2018!) |

|

#66

|

||||

|

||||

|

My ECU has been mounted under the front of my console for 8 years with no problems.

__________________

1967 Firebird Convertible Factory 400/4spd Now 462/5spd Fuel Injected http://1967firebird.atwebpages.com/ |

|

#67

|

|||

|

|||

|

Nice spot Silverbuick!

I mocked up the ECU on top of my glovebox last weekend but I'm getting more distracted by body work now. I ended up purchasing my first welder this week. Got a barely used Lincoln 3200HD welder with an auto darkening helmet, hand mask, regulator, 3 spools of wire, tips, cart and a small gas line of craigslist. Need to get gas and practice some MIG work before I start welding on my header though. Any tips/information is much appreciated at this point. Now I have something to weld in an O2 sensor bung. Just pulled the bumper off this weekend and took some time with a wire wheel around the area where the gas tank goes. I still have much more to clean but after that, I'll come in with a paint stripper then use my KBS chassis coating kit to seal up the efi gas tank and area where it bolts in. The way I'm going about it is very dirty so I hope everyone is using a breather mask when doing body work on their cars. No pictures on this but I used a 4" grinder on my rear bumper and cleaned it up very nicely. That should get painted up once I get the other work done.

|

|

#68

|

|||

|

|||

|

Where are you guys getting the wires fed through to the engine bay? I started playing around with some scenarios and I was initially thinking about sending the harness through the top of the trans tunnel.

This premade harness from FAST seems very nice. I have my battery in the trunk so I am thinking about putting all the ECU power and fuel pump wires through the passenger side sill plate...main power and alternator wire through the driver side sill plate. I've been getting caught up doing body work the past week. Just sent my intake to get cut to match the heads as well. I'll hopefully be ready to start painting the back half of the undercarriage next week then be able to get back to being concentrated on the efi components of this install...been sidetracked trying to prep and paint everything I take apart. |

|

#69

|

||||

|

||||

|

I'm doing a bit of panel work to my firewall at the moment and have welded all of the holes up. I plan on sending my body and EFI harness through the firewall using these - http://www.ebay.com.au/itm/Deutsch-H...item339bc9a3fc

Water proof and serviceability is what I'm after. The main battery terminals I plan to use this up inside the inner guard where noone will see it - http://www.ebay.com.au/itm/BLUE-SEA-...item43db69a4d9 My battery was trunk mounted and i'm toying with the idea of putting it back in the factory spot, but if I keep it in the trunk, i'll just run 2 of these studs as my car is a "half chassis" so I need to run a negative all the way to the engine or else I get really bad voltage drop when cranking as the body created too much resistance.

__________________

'71 Holden HQ Monaro - 3850lbs race weight, 400c/i - 11.4 @ 120 '66 Pontiac GTO - 389, 4 speed street cruiser |

|

#70

|

||||

|

||||

|

On both my Skylark and Firebird I feed the wires through the area right above the heater box. There was already a hole for a vacuum line, I just made it bigger and added a second one.

__________________

__________________________________________ "How I learned to stop worrying and love the OHC Pontiac L6"  The Silver Buick- '77 Skylark coupe w/455, SPX, MegaSquirt 3 & TKO-600 (Drag Week 2011, 2012 & 2015!) 1969 Firebird with a turbo'd Pontiac L6 controlled by a MegaSquirt 3 and backed with a microsquirt controlled 4L60e and 4.56 gears! (Drag Week 2018!) |

|

#71

|

||||

|

||||

|

Same here, used two existing Holes in the firewall.

Run the 12V power wires through the smaller hole and run the sensor wires through larger hole, where the heater blower motor wires are.

__________________

Its ok to giggle and snicker, Dont laugh and point |

|

#72

|

||||

|

||||

|

Quote:

http://www.newark.com/itt-cannon/192...-24/dp/47M0119 One thing to keep in mind is need to make sure all connections are spot-on, but sure you know that. Also, need to maintain shield on some leads too. It's tough to find an affordable connector, many I was sourcing were over $600 once you buy all the pieces. I did a smoothy panel on my firewall, and heck if I'm going to cut a big gaping hole in it. The way most pre-made harnesses that come from the EFI manufacturers all use the crappy looking plastic accordion hose to cover the wires, and like a 2" rubber grommet to pass through the firewall. And there's no way to disconnect it. Aircraft connectors are the way to go. And I was going to cover the wires with the expanding mesh covering, will look way nicer. .

__________________

. 1970 GTO Judge Tribute Pro-Tour Project 535 IA2 http://forums.maxperformanceinc.com/...d.php?t=760624 1971 Trans Am 463, 315cfm E-head Sniper XFlow EFI, TKO600 extreme, 9", GW suspension, Baer brakes, pro tour car https://forums.maxperformanceinc.com...ght=procharger Theme Song: http://www.youtube.com/watch?v=7zKAS...ature=youtu.be |

|

#73

|

||||

|

||||

|

Quote:

I find that even with temp/pressure sensors, I twist the wires all the way from the connector to the sensor to help with noise. Once twisted, then wrap/heatshrink the harness.

__________________

'71 Holden HQ Monaro - 3850lbs race weight, 400c/i - 11.4 @ 120 '66 Pontiac GTO - 389, 4 speed street cruiser |

|

#74

|

|||

|

|||

|

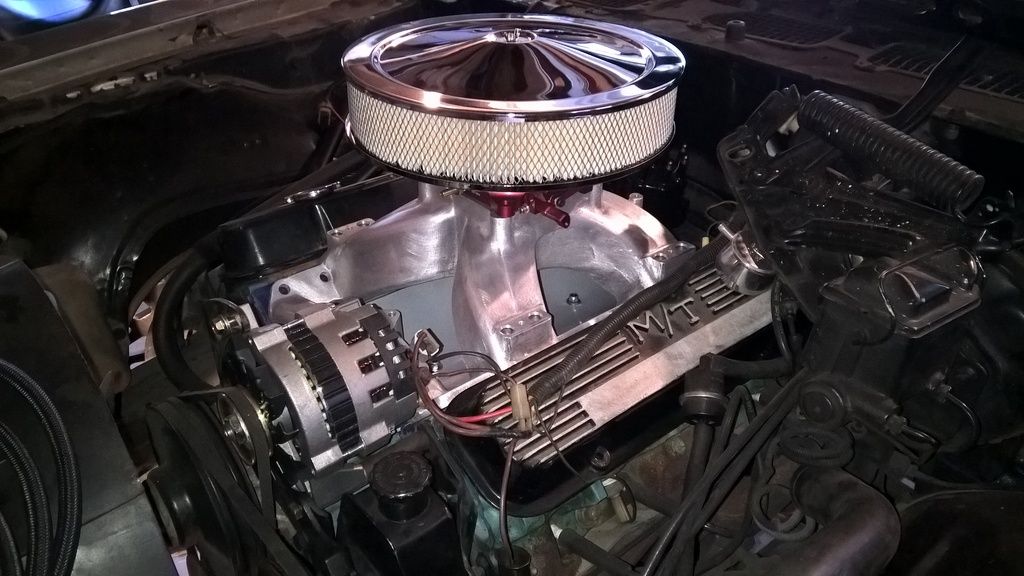

Haven't been on PY since the new change lately but I got some updates for the thread. I repainted the rear half of the underbody, got some suspension and just did a test fit on a new alternator. In regards to the efi, the alternator I just got was a built unit by a friend that owns an alternator shop. He assembled a later style GM alternator to bolt on my engine but it kicks out 180 amps and has internal/external fans. I also got an adapter plug so it plugs directly into my original harness.

|

|

#75

|

|||

|

|||

|

Been going slow on this project but making some progress. I broke one of my main ecu connectors today so I will have to replace that unfortunately. Got a new air cleaner today...

|

|

#76

|

||||

|

||||

|

You can buy Edelbrock PONTIAC intake manifolds ALREADY set up for Port Injection (Bungs) which is a good deal vs fabricating / welding on parts.

Tom V.

__________________

"Engineers do stuff for reasons" Tom Vaught Despite small distractions, there are those who will go Forward, Learning, Sharing Knowledge, Doing what they can to help others move forward. |

|

#77

|

|||

|

|||

|

That's what I have Mr. Tom. This one is the efi victor with 4500 FAST throttle body. You can see in earlier posts before I removed the Edelbrock lettering. I'm in debate between polishing it or painting stock style blue to look kind of stock.

|

|

#78

|

|||

|

|||

|

Another update to the madness and my first time trying out "porting"

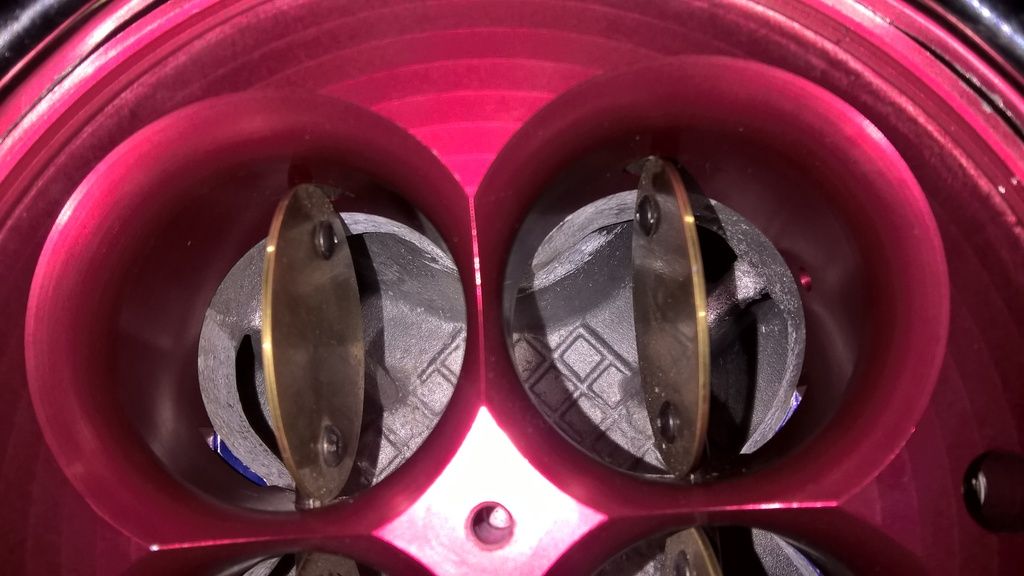

Had a lot of modifications I needed to do for the throttle body just to open and close. First off, it wouldn't bolt on correctly without a gasket because the throttle linkage and carb pad were in contact with each other. I had to grind off material along the outside of the intake. Once that was completed, I had to start opening up the plenum just so the throttle plates could open. Using Dykem and a scribe helped but I ultimately started accounting for core shift and finished everything by hand and eye. I must've had the throttle body on and off about 20 times to get it where it's at now.    Here you can see how close I got the transitions. This throttle body couldn't even open, close or even bolt on correctly prior to this!

|

|

#79

|

||||

|

||||

|

I can confirm for any EFI guys that don't want to cut a big hole in their firewall to feed wires through (and have a potential water leak each time you degrease your engine). The Deautsch plugs work FANTASTIC!. I put 3 of them in my firewall. I replaced the original chassis plug from 1971 and I put 2 of them behind my intake manifold for the EFI. If I didn't have sensors in the TH400 and was running batch fire with a normal distributor, i'd probably get away with just 1 plug. I terminated any shields through the plug too and twisted all sensor wires from the ECU to the plug and plug to the sensor which gave me zero noise.

__________________

'71 Holden HQ Monaro - 3850lbs race weight, 400c/i - 11.4 @ 120 '66 Pontiac GTO - 389, 4 speed street cruiser |

|

#80

|

|||

|

|||

|

If you can, it would be a good idea to mock up the fuel rails and injectors to see where you stand with regard to the Accufab throttle linkage.

The length of the fuel injector establishes the height of the fuel rail. Even the "shorty" injectors on my engine put the fuel rail squarely in the way of the throttle body linkage. I used a Holley throttle body, and it was a major interference and required a 1 3/4" (carb) spacer to buy clearance.  Here is a link with more pictures. http://forums.maxperformanceinc.com/...14&postcount=5

__________________

1964 Catalina 2+2 4sp, 421 Tri-power 1965 GTO, Roadster Shop chassis, 461, Old Faithful cam, KRE heads 305 CFM, Holley EFI, DIS ignition. 1969 GTO 467, Edelbrock 325 CFM, Terminator EFI 1969 Firebird Convertible |

| Reply |

|

|